Motor drives and electrical equipment using them

A driving device and motor technology, applied in the direction of motor control, starting device, AC motor control, etc., can solve problems such as poor starting, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

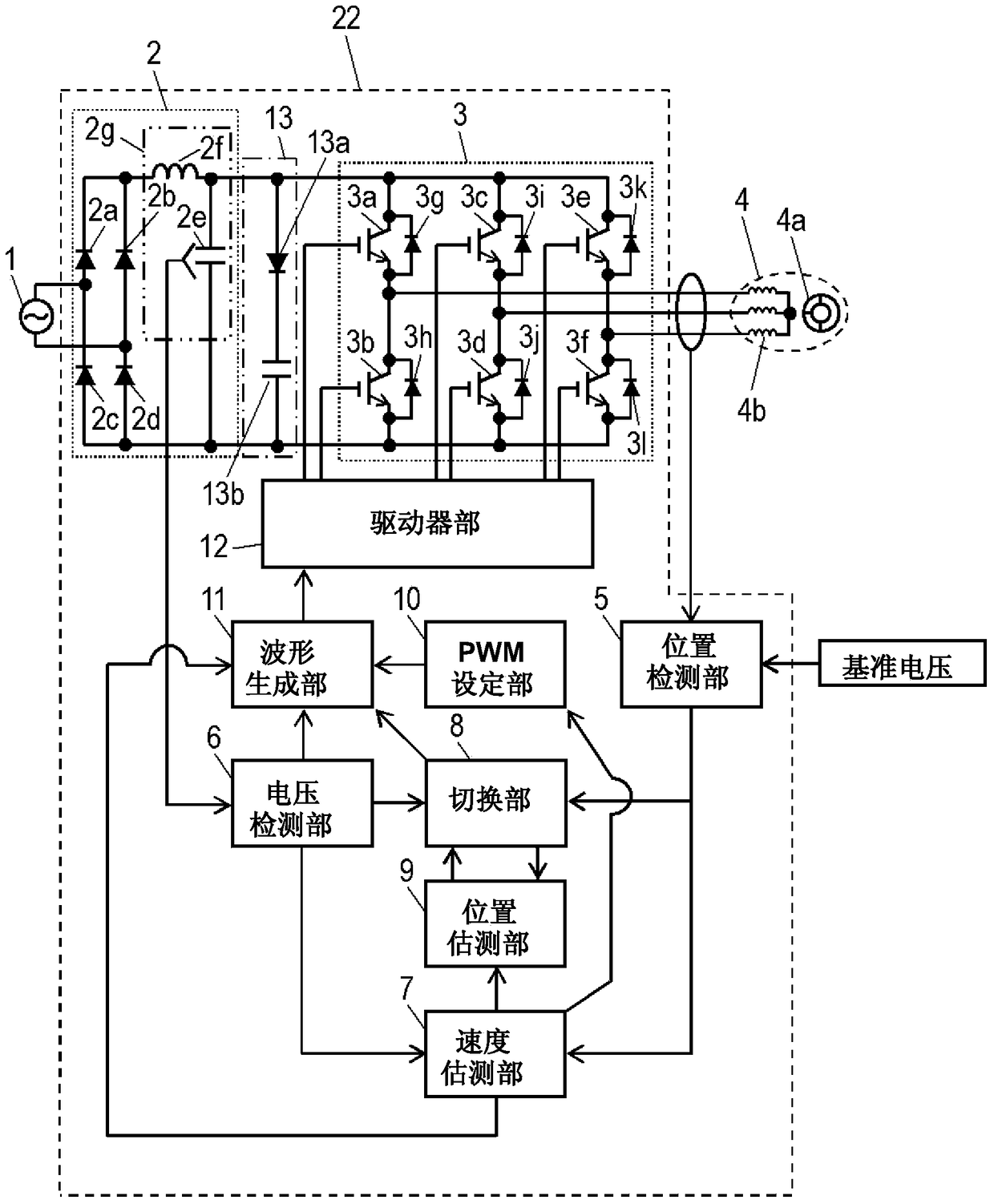

[0061] figure 1 It is a block diagram including the motor drive device 22 according to Embodiment 1 of the present invention.

[0062] exist figure 1 Among them, the AC power supply 1 is a general industrial frequency power supply, which is a 50 or 60 Hz power supply with an effective value of 100V in Japan. The motor drive unit 22 is connected to the AC power source 1 and drives the brushless DC motor 4 . Below, use figure 1 The motor drive device 22 will be described.

[0063] The rectifying and smoothing circuit 2 is a circuit for rectifying and smoothing the AC power generated by the AC power supply 1 into DC power, and includes four bridge-connected rectifying diodes 2a to 2d, a smoothing capacitor 2e, and a reactor 2f. The output of the rectification smoothing circuit 2 is input to the inverter 3 .

[0064] In addition, the smoothing capacitor 2e and the reactor 2f constitute the smoothing unit 2g, and are set so that the resonance frequency becomes a frequency 4...

Embodiment approach 2

[0123] Image 6 It is a block diagram of refrigerator 21 in Embodiment 2 of this invention.

[0124] exist Image 6 in, right with figure 1 The same symbols are attached to the same components, and detailed descriptions thereof are omitted.

[0125] Refrigerator 21 of the present embodiment uses motor drive device 22 of Embodiment 1. As shown in FIG.

[0126] In this embodiment, a reciprocating compressor 17 is used.

[0127] In the compressor 17, the rotational motion of the rotor 4a of the brushless DC motor 4 is converted into a reciprocating motion by a crankshaft (not shown). A piston (not shown) connected to the crankshaft reciprocates in a cylinder (not shown), thereby sucking in refrigerant, compressing it, and circulating it.

[0128] As the compression method (mechanism method) of the compressor, any method such as a rotary type or a scroll type can be used, and a reciprocating type is used in this embodiment. The reciprocating compressor 17 has a large inerti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com