A method for modifying cellulose acetate filter rods for cigarettes by using high-energy electron beams

A technology of cellulose acetate and high-energy electron beams, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problem that the modification effect of cigarette filter rods is not obvious, and achieve good production and application prospects, simple operation process, and water absorption performance increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Utilize high-energy electron accelerator to modify the specific steps of cellulose acetate bundle filter rod as follows:

[0016] According to the requirements of the filter rod forming production process, a cellulose acetate tow filter rod (100 / 120mm) was prepared and placed for 2 hours after forming.

[0017] Under a nitrogen atmosphere, the cellulose acetate bundle filter rod filter rod is placed on the high-energy electron beam drive track. Through the crawler transmission, the filter rod passes through the irradiation area of the electron accelerator at a constant speed. Control the irradiation dose to 50-100KGy, and irradiate the cellulose acetate bundle filter sticks one by one. Leave for 4 hours after irradiation.

[0018] After irradiation, the filter rod is immersed in 5% sodium carbonate solution for 2-3 hours, and then vacuum-dried; or directly placed at 40-60° C. and vacuum negative pressure for 10 hours.

[0019] After equilibrating under the conditio...

Embodiment 2

[0021] Utilize the cobalt source high-energy electron beam emission source to modify the concrete steps of cellulose acetate filter rod as follows:

[0022] According to the requirements of the filter rod forming production process, a cellulose acetate filter rod (100 / 120mm) was prepared and placed for 2 hours after forming.

[0023] Under nitrogen or air atmosphere, place the filter rod in the radiation sector of the cobalt source, control the radiation dose at 50-100KGy, take out the filter rod and place it for 4 hours.

[0024] After irradiation, the cellulose acetate filter stick is immersed in 5% sodium carbonate solution for 2-3 hours and then vacuum-dried; or directly placed at 40-60° C. under vacuum negative pressure for 10 hours.

[0025] After equilibrating under the condition of normal temperature and constant humidity, it is applied to the slitting and wrapping process to prepare cigarettes.

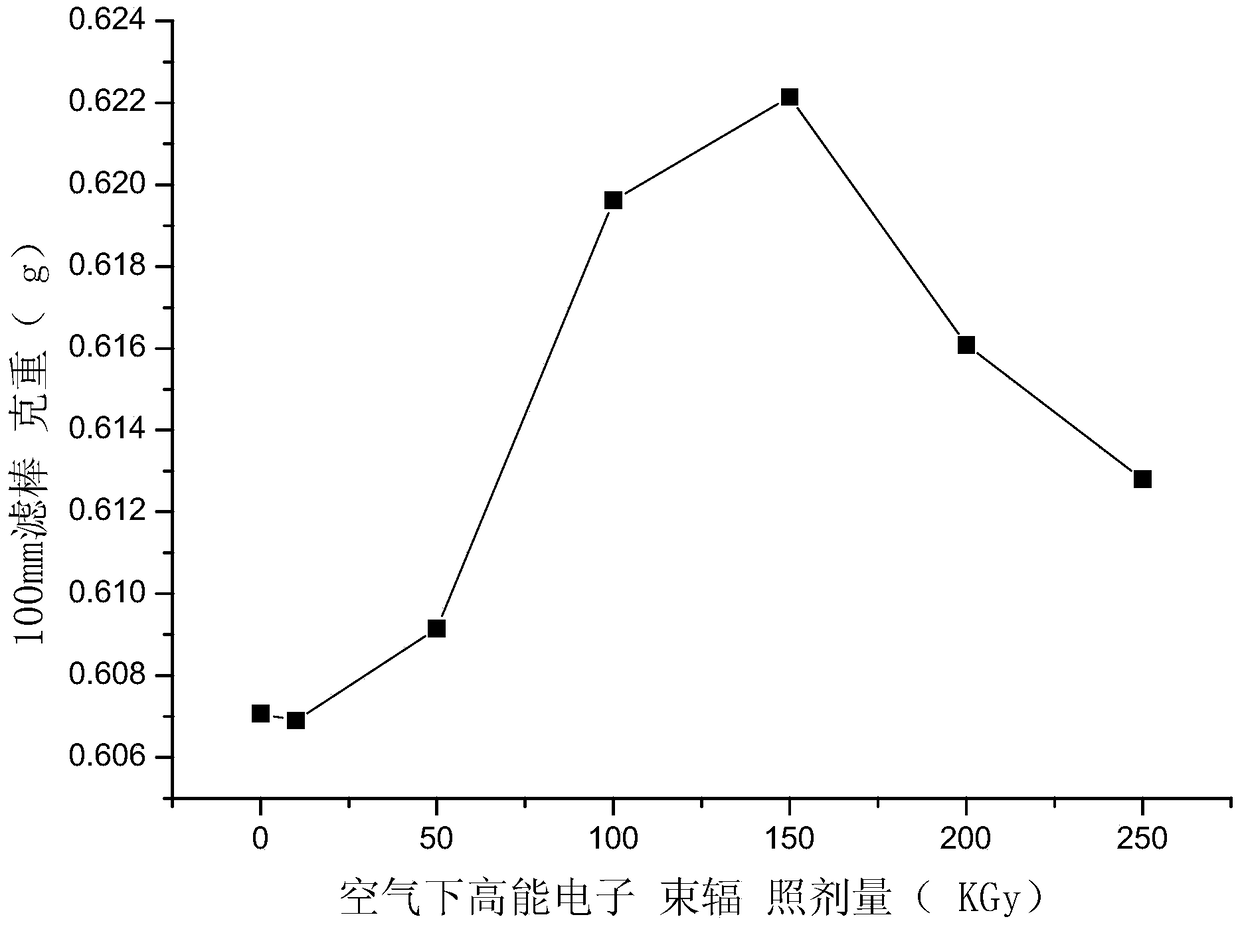

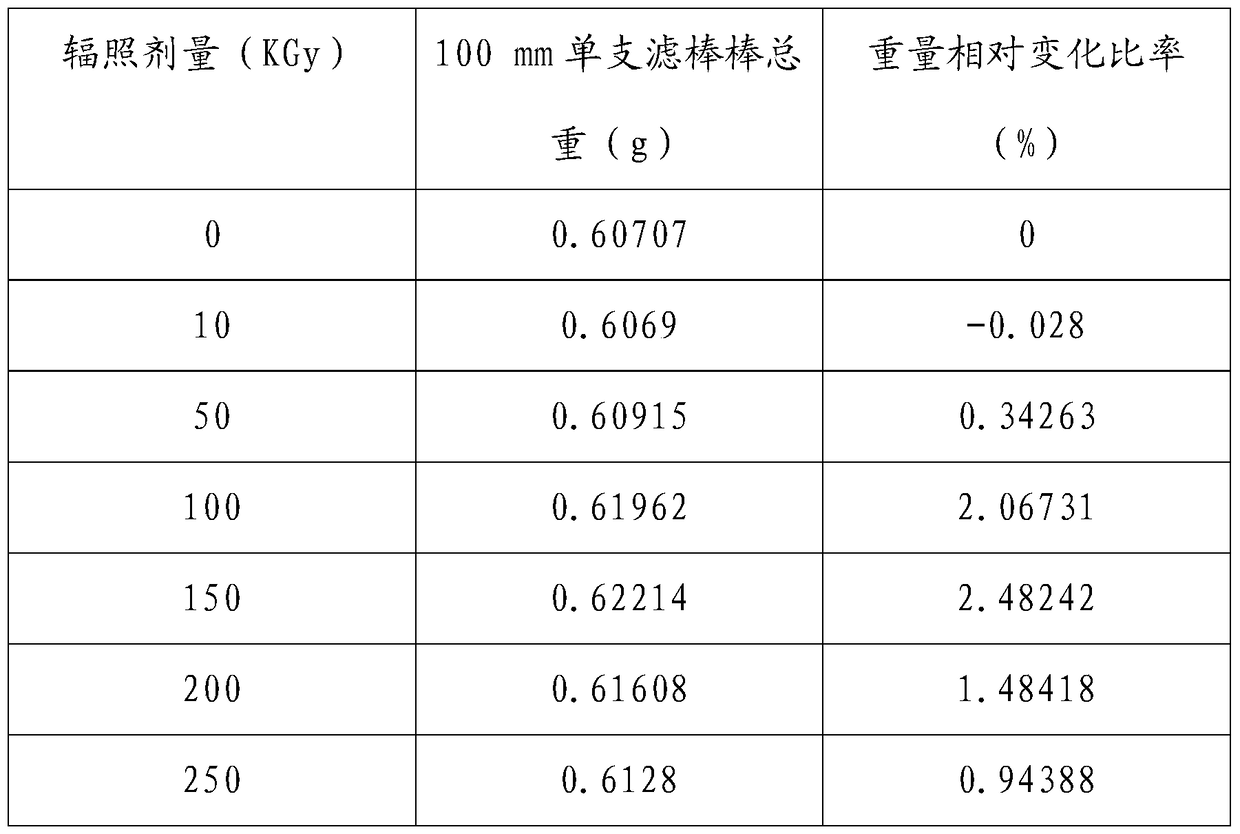

[0026] In order to prove the superiority of the preparation method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com