Middle-low temperature regenerated carbon dioxide capturing absorbent and application method thereof

A carbon dioxide and low-temperature regeneration technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as difficulty in achieving the collection rate of the absorption tower, affecting the efficiency of the collection process, and the load cannot reach expectations, etc., to achieve Effects of reduced latent and sensible heat consumption, low operating temperature, and reduced temperature rise range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

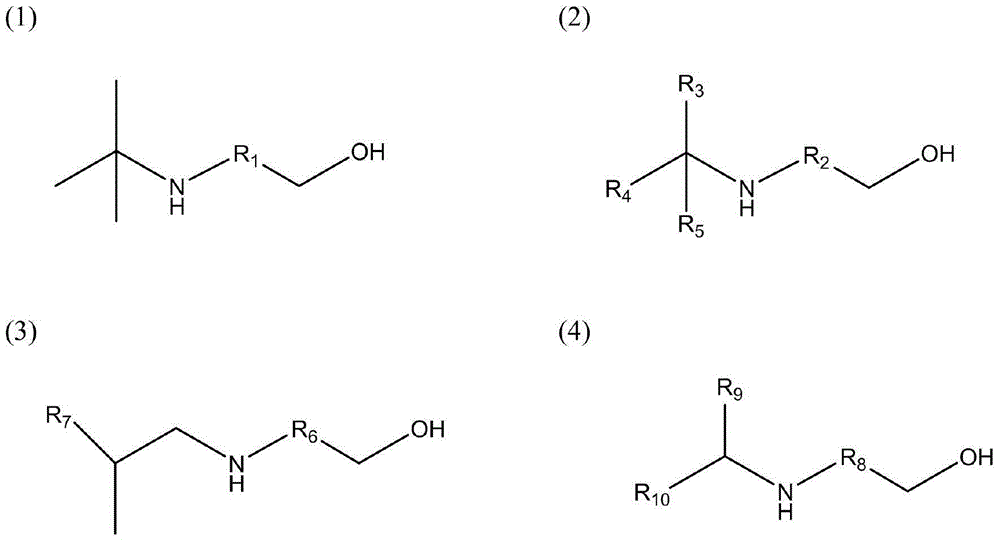

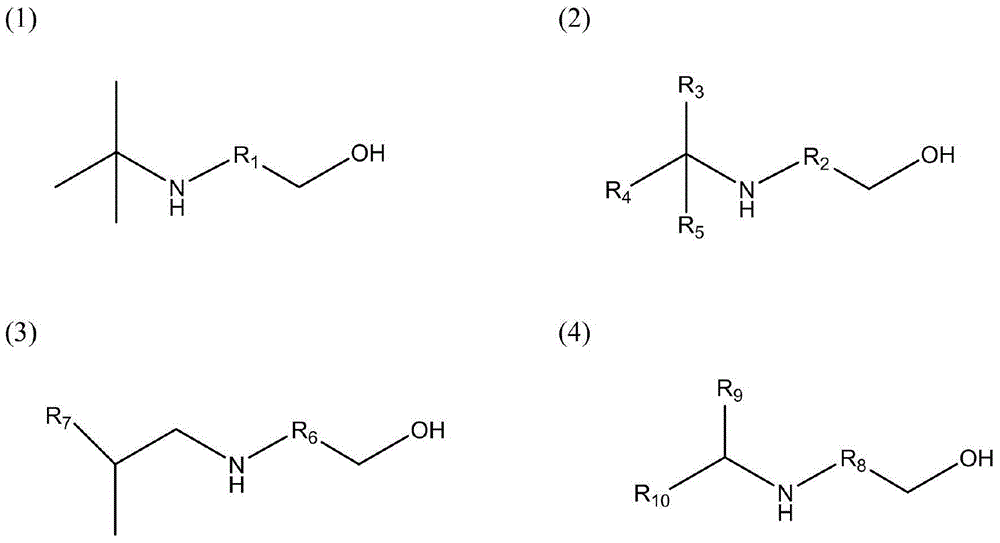

Method used

Image

Examples

Embodiment 1

[0023] A low-temperature regenerated carbon dioxide absorbent. The components are recorded in mass percent: low-temperature regenerated amine: 25.00%; pH regulator: 5.00%; auxiliary agent: 0.03%; water: the balance. The low-temperature regenerative amine is 2-(tert-butylamino)ethanol, the pH regulator is potassium carbonate, and the auxiliary agent is organosiloxane defoamer.

[0024] The method of use is: the low-temperature regenerated carbon dioxide absorbent in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 40°C, the absorption pressure: 0.1Mpa, the amount of absorbed carbon dioxide and the low-temperature regenerated amine substance The volume ratio is above 0.40. The rich liquid is preheated through the lean-rich liquid heat exchanger, and a part of carbon dioxide gas is flashed out. The flashed rich liquid enters the regeneration tower for low-temperature pyrolysis, and the regeneration forms lean liq...

Embodiment 2

[0026] A low-temperature regenerated carbon dioxide absorbent. The components are recorded in mass percent: low-temperature regenerated amine: 25.00%; pH regulator: 5.00%; auxiliary agent: 0.02%; water: the balance. The low-temperature regenerative amine is 3-(sec-butylamino)propanol, the pH regulator is potassium hydroxide, and the auxiliary agent is organosiloxane defoamer.

[0027] The method of use is: the low-temperature regenerated carbon dioxide absorbent in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 40°C, the absorption pressure: 0.1Mpa, the amount of the absorbed carbon dioxide substance and the low-temperature regeneration amine substance The amount ratio is above 0.35, the rich liquid is preheated through the lean liquid heat exchanger, and a part of carbon dioxide gas is flashed out, and the flashed rich liquid enters the regeneration tower for low-temperature pyrolysis, regenerates into lean...

Embodiment 3

[0029] A low-temperature regenerated carbon dioxide absorbent. The components are recorded in mass percent: low-temperature regenerated amine: 25.00%; pH regulator: 5.00%; auxiliary agent: 0.02%; water: the balance. The low-temperature regenerative amine is 2-(2,2-dimethylpropylamino)ethanol, the pH regulator is sodium bicarbonate, and the auxiliary agent is organosiloxane defoamer.

[0030] The method of use is: the absorbent solution in the absorption tower reacts with the gas containing carbon dioxide to form a rich liquid, the absorption temperature: 35°C, the absorption pressure: 1Mpa, the ratio of the amount of absorbed carbon dioxide to the amount of low-temperature regenerated amine is 0.45 Above, the rich liquid is preheated through the lean-rich liquid heat exchanger, and a part of carbon dioxide gas is flashed out. The flashed rich liquid enters the regeneration tower for low-temperature pyrolysis, regenerates into lean liquid and produces carbon dioxide, and the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com