Low-temperature lubricating supply device, high-speed stamping die with same and control method thereof

A supply device and low-temperature lubrication technology, which is applied in the direction of lubricating parts, engine lubrication, forming tools, etc., can solve the problems of shortening the service life of high-speed stamping dies, heat dissipation, and reducing plasticity, so as to ensure stamping accuracy and production efficiency , Reduce deformation and damage, improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

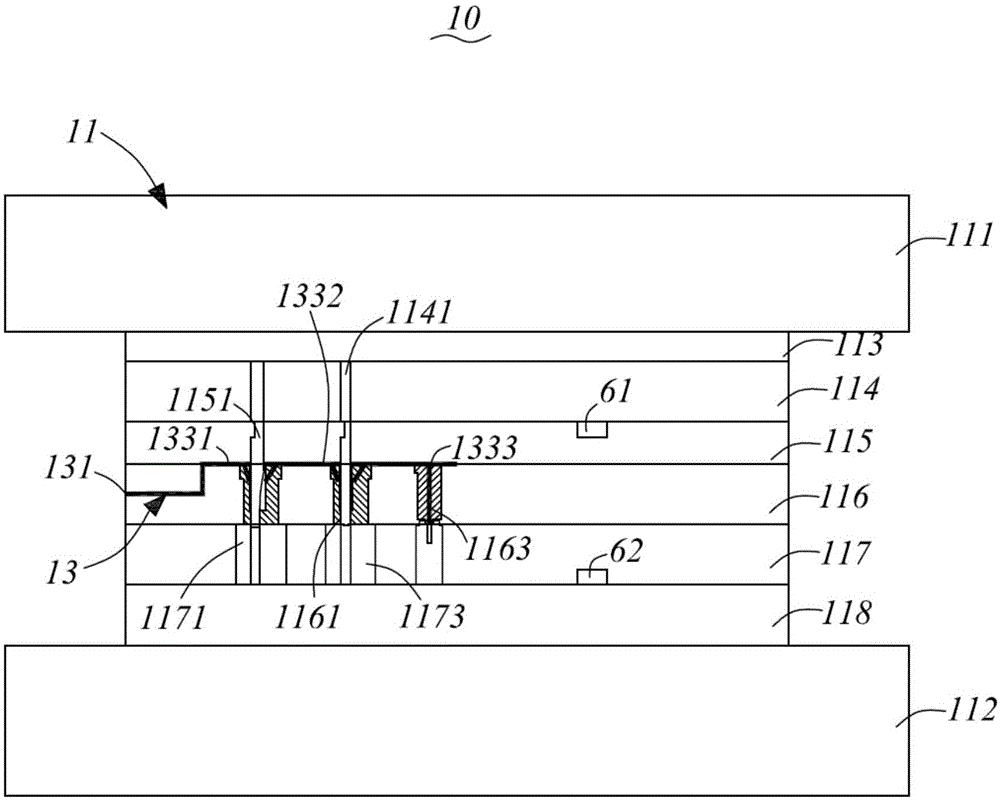

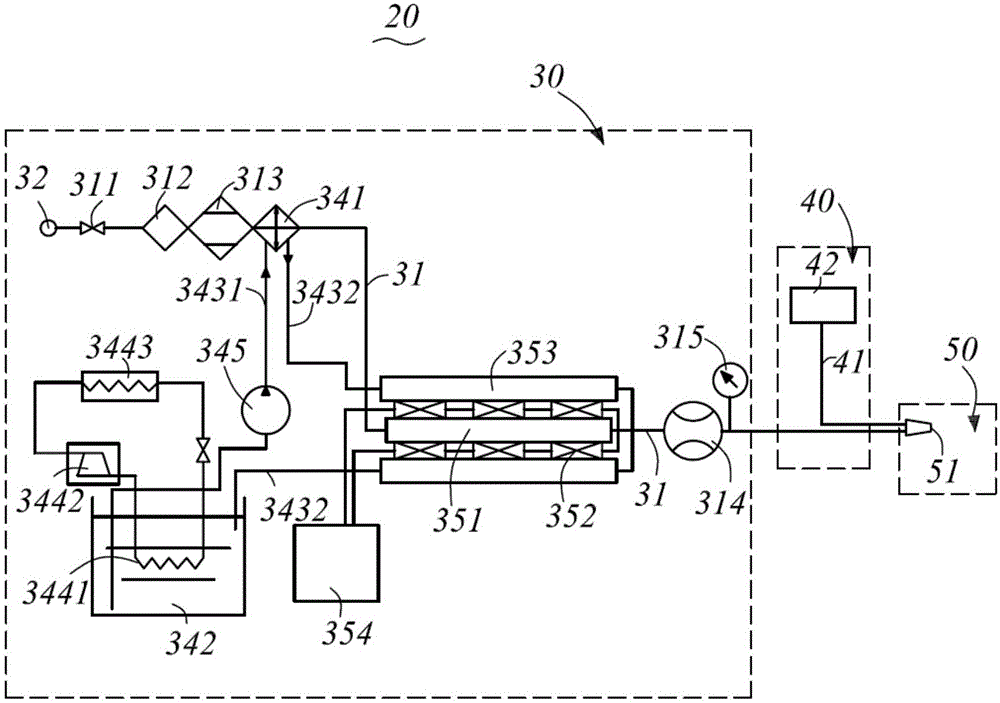

[0039] combine figure 1 , figure 2 As shown, the high-speed stamping die provided by the present invention includes: a stamping body 10 , and a low-temperature lubrication supply device 20 .

[0040] The stamping body 10 includes: a stamping processing area 11 , and oil and gas passages 13 distributed in the stamping body.

[0041] The stamping processing area 11 includes: an upper die base 111, a lower die base 112, and a forming plate group (not shown) arranged between the upper die base 111 and the lower die base 112, and the forming plate set is sequentially arranged from top to bottom Includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com