Slurry supply system of ceramic sanitary ware high-pressure slurry injection production line

A high-pressure grouting and production line technology, applied in supply devices, manufacturing tools, etc., can solve the problems of not being too long, reducing mud performance, and large fluctuations in slurry temperature, avoiding local overheating, meeting slurry supply requirements, and improving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

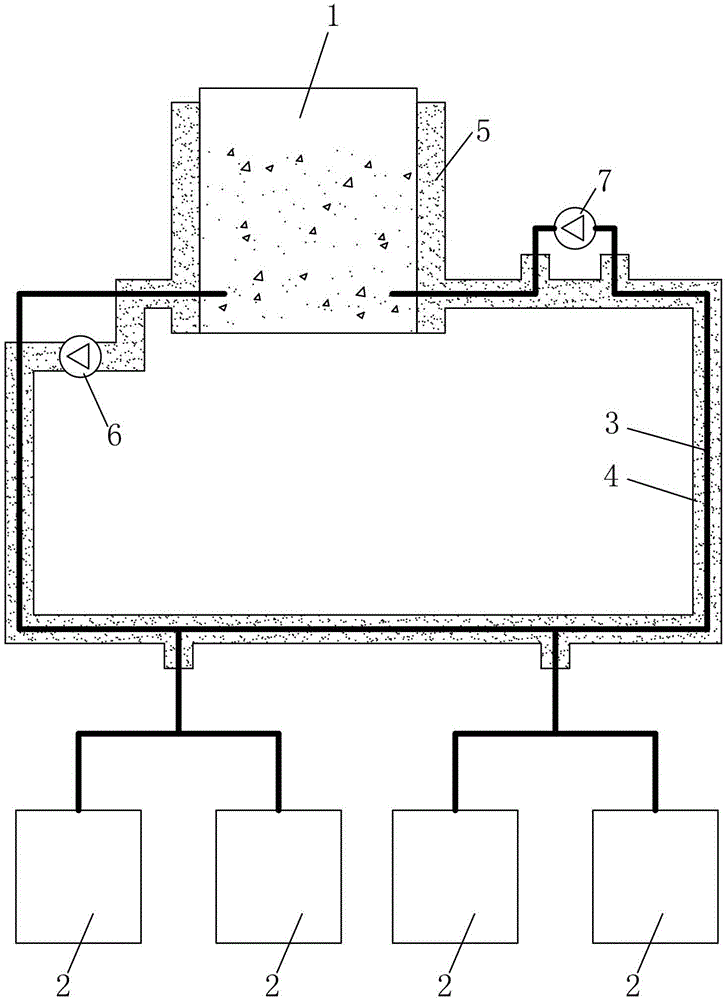

[0012] see figure 1 According to the slurry supply system of a high-pressure grouting production line for ceramic sanitary ware provided by the present invention, it includes a slurry tank 1, a slurry delivery pipe 3 is connected between the slurry tank 1 and the grouting machine 2, and the slurry delivery pipe 3 is wrapped in In the hot water pipe 4. The slurry delivery pipe 3 is represented by a thick solid line among the figures. The interface of the slurry delivery pipe 3 on the mud tank 1 is located below the slurry liquid level in the mud tank 1 . The mud tank 1 is provided with an agitator (the agitator is omitted in the figure). The outer wall of the mud tank 1 is provided with a hot water interlayer 5 for storing hot water, and the first and last ends of the hot water pipe 4 are connected with the hot water interlayer 5 to form a hot water circulation loop. A water pump 6 is connected in series in the hot water circulation circuit, and the water pump 6 drives the h...

Embodiment 2

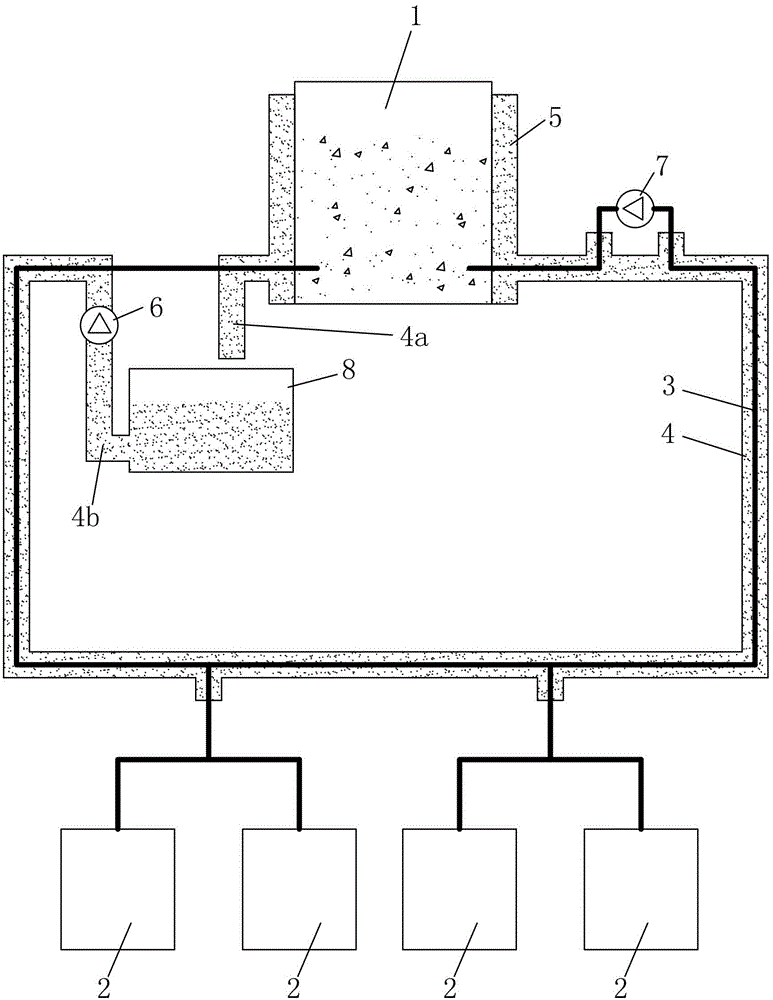

[0017] see figure 2 , the present embodiment adds a reservoir 8 on the basis of the first embodiment. The water storage tank 8 is connected in series in the hot water circulation circuit. The water inlet of the reservoir 8 is connected to the water outlet of the hot water interlayer 5 through a section of hot water pipe 4a, and the water outlet of the reservoir 8 is connected to the suction port of the water pump 6 through another section of hot water pipe 4b. The reservoir 8 has the function of stabilizing the temperature of the hot water, and the reservoir can be used to conveniently adjust the temperature of the hot water, replenish the hot water, adjust the water quality, and achieve the purpose of stably regulating the hot water. The water storage tank 8 can be heated by electricity or by means of a heat exchanger to generate hot water.

[0018] Other structures of this embodiment are the same as those of Embodiment 1.

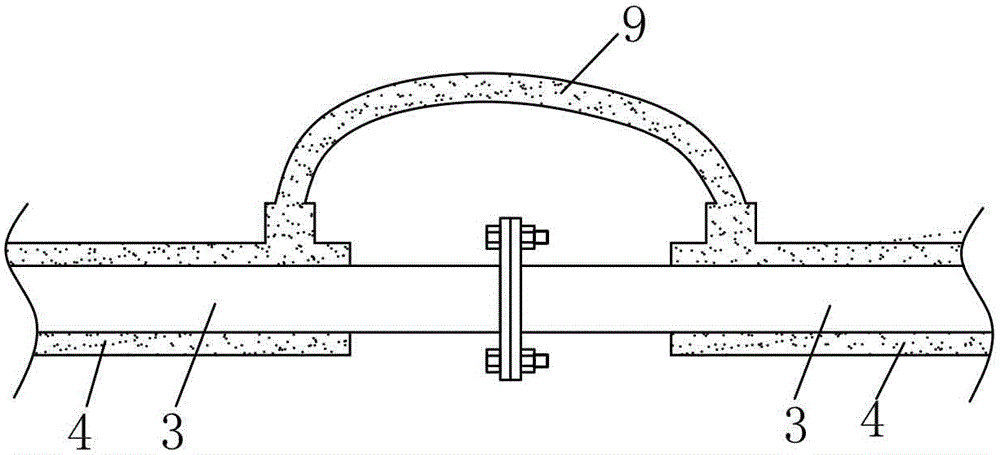

[0019] In the above example, figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com