Dry-mixed mortar dust-proof agent and dry-mixed mortar containing same

A technology of dry powder mortar and dustproof agent, applied in the field of dry powder mortar dustproof agent and dry powder mortar, can solve problems such as affecting the physical and mental health of air quality operators, and achieve obvious dust collection effect, reduce cracking, and add less effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Preparation of dry powder mortar dustproof agent

[0016] (1) Grind the straw into 0.2-0.3mm pieces in a pulverizer, soak in hot water at 95°C for 2 hours, and stir for 20 minutes with a high-speed disperser with a speed of 800-2000 rpm, and then use a wire mesh Filtration and drying to obtain dry fibers;

[0017] (2) Stir the fibers obtained in step (1) with a weight component of 70% and 5% sodium bentonite in a mixer for 20 minutes, and then use a sprayer to spray 25% simethicone oil into the mixer, and continue Stir for 20 minutes until uniform to obtain a powder dustproof agent.

[0018] 2. Preparation of dry powder mortar

[0019] (1) Tile bonding mortar formula containing dustproof agent (weight ratio)

[0020] Cement 400

[0021] Quartz sand (40-140 mesh) 600

[0023] Redispersible latex powder 15

[0024] Anti-dust agent 8

[0025] (2) Preparation

[0026] According to the above formula, add cement, quartz sand, cellulose...

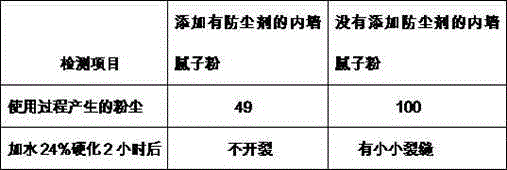

Embodiment 2

[0033] 1. Preparation of dry powder mortar dustproof agent

[0034] (1) Crush the straw into 0.1-0.2mm fines in a pulverizer, soak in hot water at 90°C for 2 hours, and stir for 25 minutes with a high-speed disperser at a speed of 800-2000 rpm, then filter with a steel mesh , drying to obtain dry fibers;

[0035] (2) Stir the fiber obtained in step (1) with a weight component of 75% and 10% calcium-based bentonite in a mixer for 20 minutes, then use a sprayer to spray 15% amino silicone oil into the mixer, and continue stirring for 20 minutes until uniform, to obtain a powder dustproof agent.

[0036] 2. Preparation of dry powder mortar

[0037] (1) Formula of interior wall putty powder containing dustproof agent (weight ratio)

[0038] Ash Calcium 150

[0039] Heavy calcium (325 mesh) 850

[0041] Redispersible latex powder 5

[0042] Anti-dust agent 8

[0043] (2) Preparation

[0044] Add ash calcium, heavy calcium, cellulose ether, redi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com