Slurry with time-variable viscosity and preparation method thereof

A time-varying, slurry technology, applied in the field of viscosity time-varying slurry and its preparation, can solve the problems of complex production process, unsuitable use, long setting time, etc., and achieve rich material sources, good pourability, and high water retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

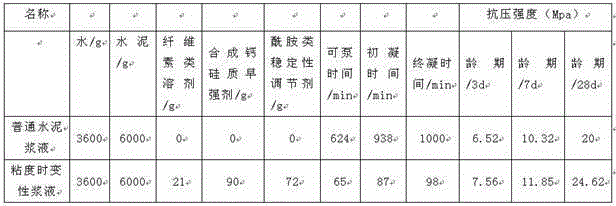

[0047] A time-varying viscosity slurry, comprising the following components in parts by weight:

[0048] Cement -------- 10 parts

[0049] Cellulose solvent --------0.02 parts

[0050] 0.5 parts of synthetic calcium and silicon early strength agent

[0051] 0.05 part of amide stability modifier

[0052] 5 parts of water.

[0053] The cellulose solvent is hydroxyethylmethylcellulose.

[0054] The synthetic calcium siliceous accelerator includes calcium nitrate and sodium silicate.

[0055] The amide stability modifier includes polyacrylamide and sodium acrylate.

[0056] This example is the most basic implementation mode. The time-varying viscosity slurry formed by this specific ratio has less raw material consumption, lower production cost, and has the characteristics of rapid strength growth in the early stage and high strength in the later stage, and good pourability.

[0057] The performance index of viscosity time-varying slurry is:

[0058] Pumpable time: 65min

[0...

Embodiment 2

[0064] A time-varying viscosity slurry, comprising the following components in parts by weight:

[0065] Cement -------- 20 parts

[0066] Cellulose solvent --------0.07 parts

[0067] Synthetic calcium silicate early strength agent 1 part

[0068] 0.08 part of amide stability modifier

[0069] 8 parts of water.

[0070] The cellulose solvent is hydroxyethylmethylcellulose.

[0071] The synthetic calcium siliceous accelerator includes calcium nitrate and sodium silicate.

[0072] The amide stability modifier includes polyacrylamide and sodium acrylate.

[0073] This embodiment is a better implementation mode. The time-varying viscosity slurry has the characteristics of fast strength growth in the early stage and high strength in the later stage, and has good groutability.

Embodiment 3

[0075] A time-varying viscosity slurry, comprising the following components in parts by weight:

[0076] Cement -------- 30 parts

[0077] Cellulose solvent --------0.1 parts

[0078] Synthetic calcium silicate early strength agent 2 parts

[0079] 0.1 part of amide stability modifier

[0080] 10 parts of water.

[0081] The cellulose solvent is hydroxyethylmethylcellulose.

[0082] The synthetic calcium siliceous accelerator includes calcium nitrate and sodium silicate.

[0083] The amide stability modifier includes polyacrylamide and sodium acrylate.

[0084] This embodiment is the best implementation mode. The cellulose solvent adopts hydroxyethyl methylcellulose, which has good salt tolerance and is easily soluble in water. When metal salts or organic electrolytes exist, it is relatively stable in aqueous solution. It has high viscosity and high water retention; synthetic calcium siliceous early strength agents include calcium nitrate and sodium silicate, which are r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com