A method for separating heparinoids from heparin by-product waste protein

A technology for heparin by-products and proteins, applied in the field of separating heparinoids from heparin by-products, can solve the problems of difficult separation of effective substances, waste of resources, etc., and achieve the effects of low cost, cost saving, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

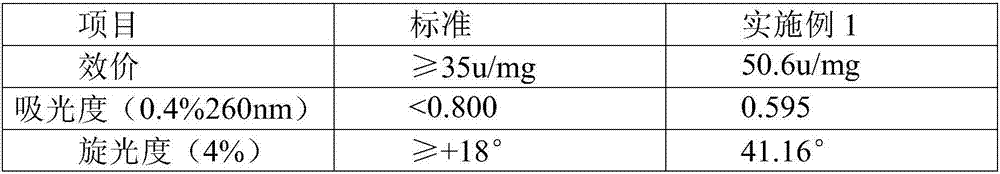

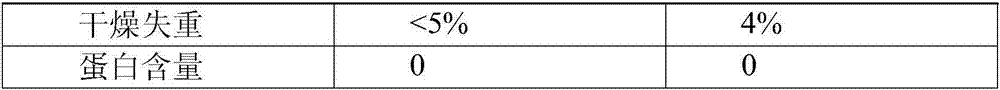

Embodiment 1

[0023] Take 8L of heparin by-product waste protein and dissolve it with 16L of water. According to the ratio of adding 6g of resin per liter of protein, add 48g of resin for adsorption. The adsorption temperature is 59°C, the pH is 7.67, the salt concentration is 0.75mol / L, and the adsorption time is 8h. Collect the resin after adsorption, add 0.82mol / L sodium chloride solution for washing, add 4.5mol / L sodium chloride solution for elution after washing for 20 minutes, collect eluent after 4 hours of elution, add 300ml 90% ethanol, precipitation 16h. After the precipitation, the ethanol in the upper layer was poured off, and 180ml of water was added for dissolution. Use 30% sodium hydroxide to adjust the pH to 11.22, add 2ml of 30% hydrogen peroxide, stir evenly, and the oxidation time is 6 hours. After the oxidation is completed, use 8% hydrogen chloride to adjust the pH to 6.05, and add 40% hydrogen sulfite drop by drop Sodium, use Merck test paper to judge whether there a...

Embodiment 2

[0027] Take 8L of heparin by-product waste protein and dissolve it with 16L of water. According to the ratio of adding 8g of resin per liter of protein, 64g of resin was added for adsorption. The adsorption temperature was 59°C, the pH was 7.79, the salt concentration was 0.78mol / L, and the adsorption time was 8h. Collect the resin after adsorption, add 0.82mol / L sodium chloride solution for washing, add 4.5mol / L sodium chloride solution for elution after washing for 20 minutes, collect eluent after 3 hours of elution, add 300ml 90% ethanol, precipitation 16h. After the precipitation, the ethanol in the upper layer was poured off, and 180ml of water was added for dissolution. Use 30% sodium hydroxide to adjust the pH to 11.3, add 2ml of 30% hydrogen peroxide, stir evenly, and the oxidation time is 6 hours. After the oxidation is completed, use 8% hydrogen chloride to adjust the pH to 6.83, and add 40% hydrogen sulfite drop by drop Sodium, use Merck test paper to judge whethe...

Embodiment 3

[0031] Take 10L of heparin by-product waste protein and dissolve it in 25L of water. According to the ratio of adding 7g of resin per liter of protein, 70g of resin was added for adsorption. The adsorption temperature was 59°C, the pH was 7.96, the salt concentration was 0.78mol / L, and the adsorption time was 6h. Collect the resin after adsorption, add 0.82mol / L sodium chloride solution for washing, add 4.5mol / L sodium chloride solution for elution after washing for 20 minutes, collect eluent after 4 hours of elution, add 410ml 90% ethanol, precipitation 16h. After the precipitation, the ethanol in the upper layer was poured off, and 360ml of water was added for dissolution. Use 30% sodium hydroxide to adjust the pH to 11.36, add 4ml of 30% hydrogen peroxide, stir evenly, and the oxidation time is 9 hours. After the oxidation is completed, use 8% hydrogen chloride to adjust the pH to 7, and add 40% hydrogen sulfite drop by drop Sodium, use Merck test paper to judge whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com