Washable touch screen temporary protection ink as well as preparation method and application thereof

A temporary protection, touch screen technology, applied in the field of ink, can solve the problems of touch screen cover glass or ITO glass corrosion, operator health damage, slow film stripping speed, etc., to achieve easy expansion of production and convenient cleaning process. , the effect of less control points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

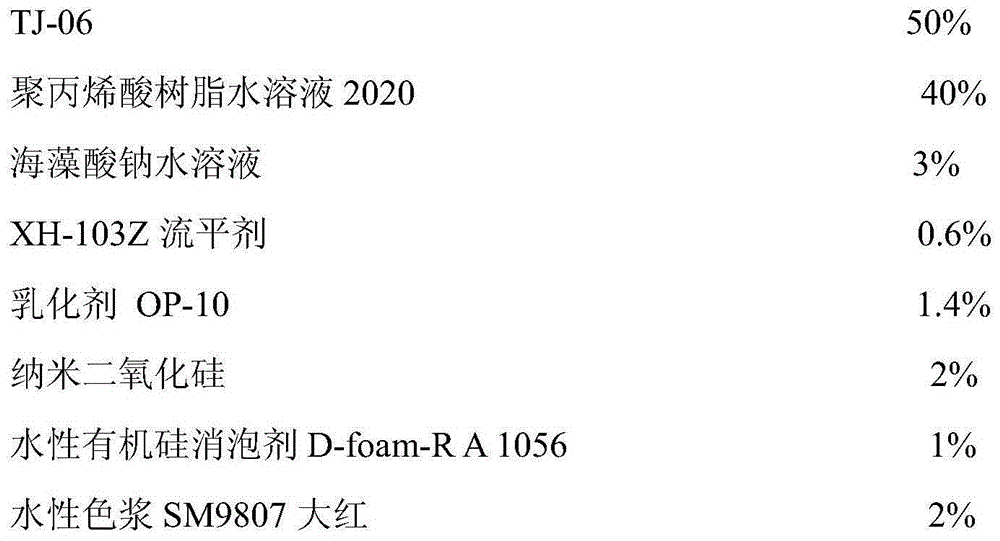

Examples

Embodiment 2

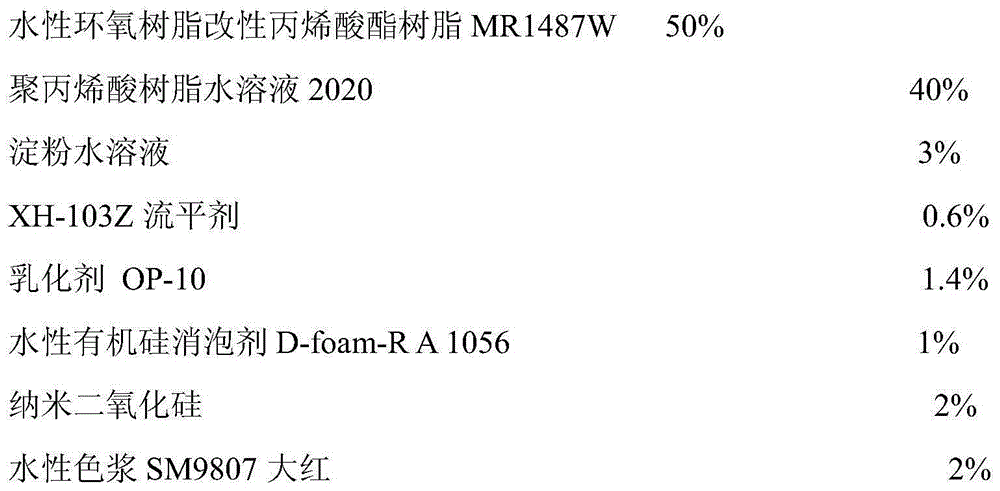

[0060] A washable touch screen temporary protection ink, first equipped with a water-based acrylic modified epoxy resin aqueous solution with a solid content of 40%, and a starch aqueous solution with a solid content of 5%, and then weighed according to the mass ratio:

[0061]

[0062] Add the above-mentioned polyacrylic acid resin aqueous solution, XH-103Z leveling agent, and nano silicon dioxide into the disperser and stir at 400r / min for 10min until uniform, then add other remaining raw materials and stir at 300r / min for 50min to obtain ink.

[0063] The obtained ink was printed with a 200-mesh screen brush on a 10 μm coating film on the above-mentioned touch screen cover glass and ITO glass, first dried at 80°C for 30 minutes, and then placed in an oven at 200°C for 2 hours before testing. The hardness tested by the GB / T6739 method is B, and the film is smooth and yellowish. The effect of film removal in 50°C water is about 90s and it falls off in pieces.

Embodiment 3

[0065] A washable touch screen temporary protection ink, first equipped with a water-based amino resin aqueous solution with a solid content of 40%, and an aqueous solution of sodium alginate with a solid content of 5%; then weighed according to the mass ratio

[0066]

[0067] Add the above-mentioned polyacrylate emulsion and XH-103Z leveling agent into the disperser and stir at 400r / min for 15min until uniform, then add other remaining raw materials and stir at 300r / min for 60min to obtain the ink.

[0068] The obtained ink was printed with a 200-mesh screen brush on a 10 μm coating film on the above-mentioned touch screen cover glass and ITO glass, first dried at 80°C for 30 minutes, and then placed in an oven at 200°C for 2 hours before testing. The hardness tested by the GB / T6739 method is B, the film is smooth and light yellow, and the effect of film removal in 50°C water is about 50s, and it will fall off in large blocks.

[0069] Implementation 4

[0070] A washabl...

Embodiment 6

[0080] A kind of washable touch screen temporary protective ink, first equipped with a water-based polyacrylate aqueous solution with a solid content of 40%, and an aqueous solution of polyvinylpyrrolidone (K30) with a solid content of 40%

[0081] Then weigh it according to the mass ratio

[0082]

[0083]

[0084] Add the above polyacrylic acid resin aqueous solution, XH-103Z leveling agent and nano silicon dioxide into the disperser and stir at 400r / min for 10min until uniform, then add other remaining raw materials and stir at 300r / min for 40min to obtain ink.

[0085] The obtained ink was printed with a 200-mesh screen brush on a 10 μm coating film on the above-mentioned touch screen cover glass and ITO glass, first dried at 80°C for 30 minutes, and then placed in an oven at 200°C for 2 hours before testing. The hardness tested by the GB / T6739 method is 2B, the film is smooth and yellowish, and the film removal effect in 50°C water is about 45s, and it will fall off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com