Mucilage glue sheet for tire bonding

An adhesive sheet and bonding technology, which can be used in film/sheet adhesives, adhesives, non-polymer organic compound adhesives, etc., which can solve the problems of poor viscosity and insufficient tensile strength of adhesive sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

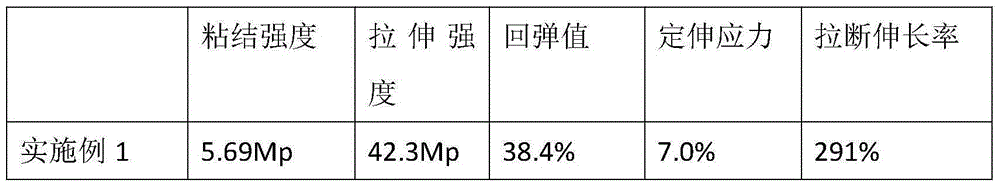

Examples

Embodiment Construction

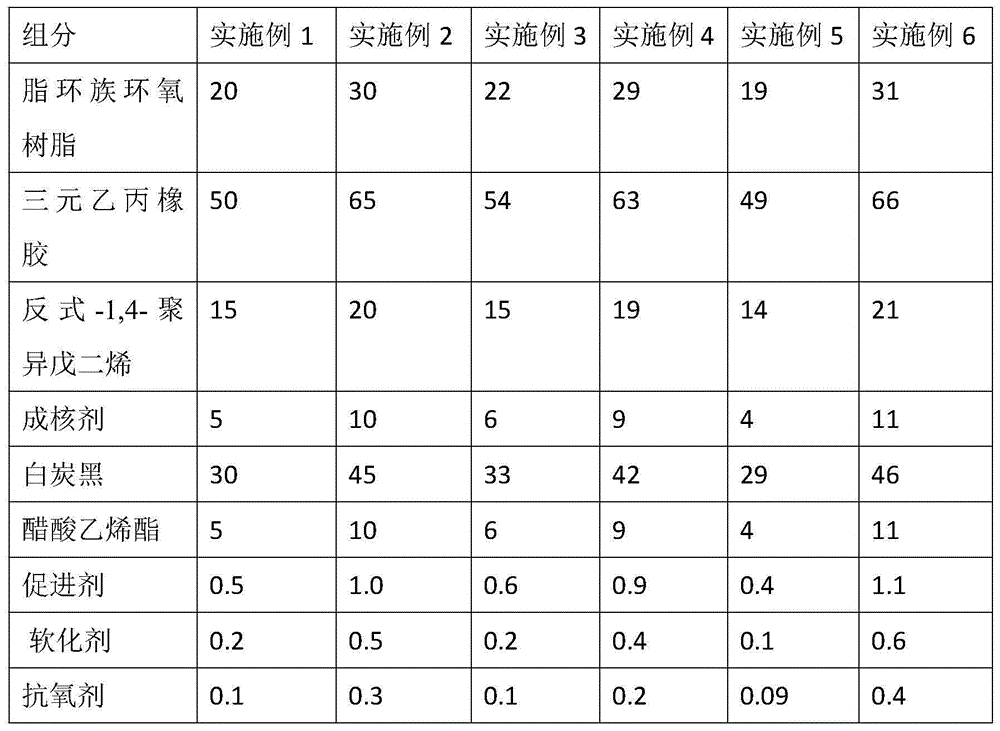

[0009] 1. The components of this formula will be proportioned in different parts by mass, as shown in the following table.

[0010]

[0011] Table 1

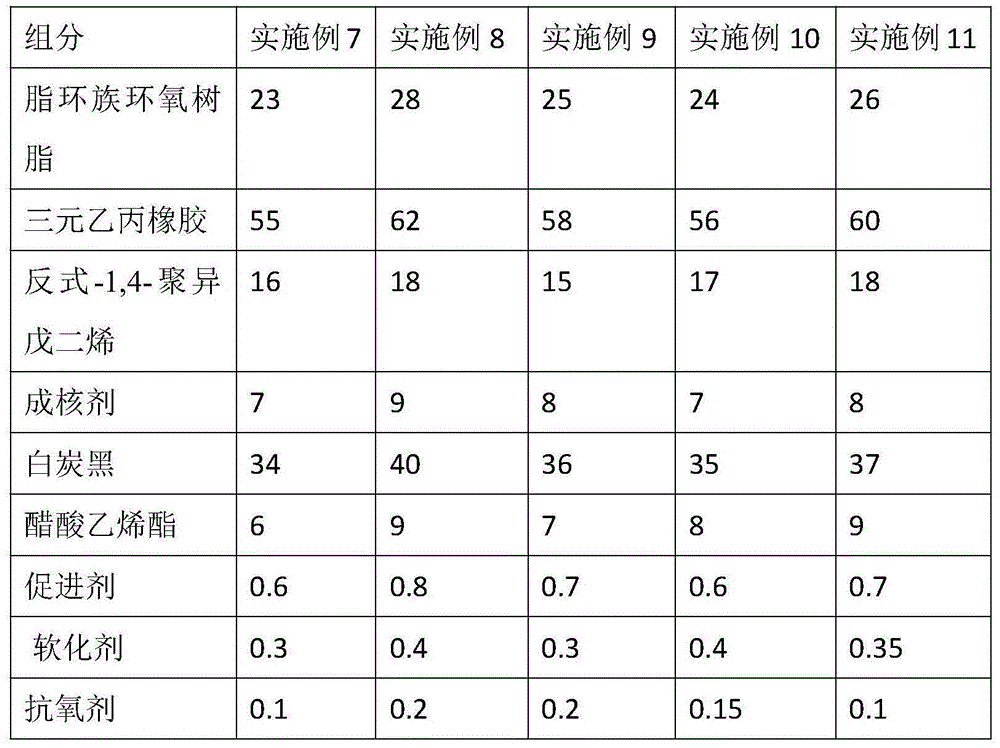

[0012]

[0013] Table 2

[0014] Two, the preparation method of above-mentioned each embodiment is all the same, and concrete steps are as follows:

[0015] Step 1: put alicyclic epoxy resin, EPDM rubber, trans-1,4-polyisoprene, nucleating agent, and white carbon black into an internal mixer for mastication, wherein, the dense The rotation speed of the mill is 60r / min-70r / min, the internal pressure is 4Mp-5Mp, the heating temperature is 160°C-165°C, after plasticizing for 2-3min, discharge and stand for 5-7 hours to obtain glue A.

[0016] Step 2: Stir 6 parts of iodonitro blue tetrazolium chloride and 18 parts of ethylene glycol solution evenly to prepare an accelerator for future use.

[0017] Step 3: Put the glue A, vinyl acetate, softener and antioxidant obtained in step 1 into the internal mixer for mixing, and slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com