Semicoke passivation technology and system

A semi-coke and process technology, applied in the field of passivation process and passivation system, can solve the problems of high operating cost, complicated operation, poor resistance effect, etc., and achieve the effect of solving spontaneous combustion, reducing costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail as follows:

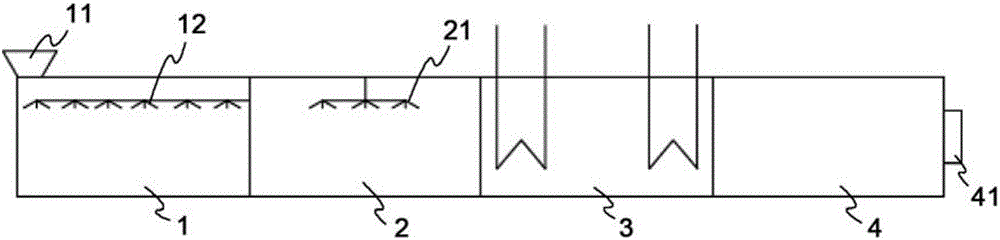

[0038] Such as figure 1 As shown, the semi-coke passivation system described in the present invention includes a chilling zone 1, a spraying zone 2, a cooling zone 3 and an oxidation zone 4 arranged laterally in sequence, and a semi-coke conveying device arranged in the above-mentioned areas. The focal conveying device can transfer the semi-focus according to the order of the above-mentioned sequentially arranged areas. In addition, the semi-coke passivation system also includes a water supply device to provide cooling water to the nozzles or water pipes in the quenching zone 1, the spraying zone 2 and the cooling zone 3.

[0039] The quenching zone 1 is provided with a feed inlet 11, and the top of the quenching zone 1 is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com