Gearbox lubricating agent composition and preparation method thereof

A technology of lubricant composition and gearbox, which is applied in the fields of gearbox lubricant composition and its preparation, anti-leakage lubricant composition and its preparation, and can solve the problem of unreasonable structural design of the reducer and leakage of the seal in the gearbox To achieve excellent low-speed and heavy-load shear stability, reduce heat, and inhibit tooth surface pitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of a gearbox lubricant composition, comprising the step of mixing the components of the composition.

[0040] Preferably, the method comprises the steps of:

[0041] (1) Pour the base oil into the stainless steel blending kettle, stir evenly, and heat up to 70-90°C;

[0042] (2) Pour the adhesive into the stainless steel mixing kettle, keep warm and stir evenly for 20-30 minutes;

[0043] (3) Pour polyurea-based grease into a stainless steel blending kettle, keep warm and stir evenly for 30-40 minutes;

[0044] (4) Cool down to 45-55°C, put anti-micropitting additives, extreme pressure anti-wear agents, antioxidants, and friction modifiers into the stainless steel blending kettle, keep warm and stir evenly for 30-40 minutes;

[0045] (5) The material in the stainless steel blending kettle is beaten out, and the finished composition is obtained after grinding.

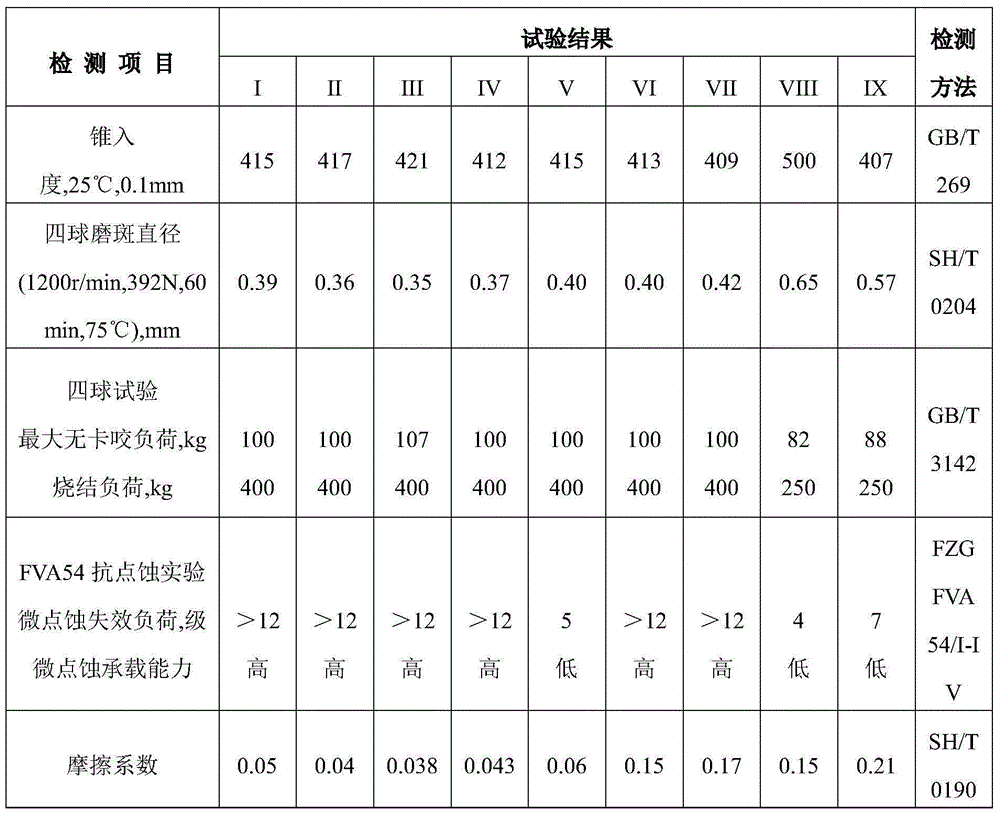

Embodiment 1

[0048] Mix 42 parts of pentaerythritol ester base oil (U.S. Hatco company, brand: HATCOL3320, the same below) with 5 parts of cyclohexane diisocyanate (Yutai Haina Environmental Protection Technology Co., Ltd., brand: MDI-100), and heat to Dissolved at 75°C to obtain the first solution; 45 parts of pentaerythritol ester base oil and 4 parts of octadecylamine (Sichuan Tianyu Oleochemical Co., Ltd., brand: 9518) were mixed, heated to 75°C, and then 2 parts of aniline ( Dongying Longxing Chemical Co., Ltd., brand: aniline) and 2 parts of methylaniline (Shanghai Yiji Industrial Co., Ltd., brand: methylaniline), stir evenly to obtain the second solution; inject the first solution into the second solution Mix and stir at a constant temperature, then raise the temperature to 160°C, heat and stir to obtain polyurea-based grease.

[0049] Pour 23.5 parts of base oil polyalphaolefin (ExxonMobil Company of the United States, brand SPEOTRASYN40, the same below) and 25 parts of dipentaeryt...

Embodiment 2

[0051] Pour 23.5 parts of base oil polyalphaolefin and 25 parts of dipentaerythritol ester into a stainless steel blending kettle, stir evenly and raise the temperature to 80°C; put 8 parts of adhesive polyisobutylene PB24000 and double ester Priolube39867 parts into a stainless steel blending kettle, and heat evenly Stir for 30 minutes; put 30 parts of polyurea-based grease (preparation method is the same as in Example 1) into the blending kettle, keep warm and stir evenly for 40 minutes; 2.5 parts of phosphoric acid, 1 part of extreme pressure anti-wear agent methylene bis-dibutyl dithiocarbamate (Vanderbilt Company of the United States, brand Vanlube7723, the same below), 1 part of amine phosphate compound, antioxidant P, 1 part of p-octyl diphenylamine (Vanderbilt Company of the United States, brand Vanlube81, the same below), 1 part of friction modifier epoxy oleate (Wroda Company of the United Kingdom, brand PerfadFM3339, the same below), and inject The blending kettle w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com