Fireproof yarn high in limit oxygen index, preparation method of fireproof yarn and fabric of fireproof yarn

A technology of limiting oxygen index and yarn, applied in the field of high limiting oxygen index fireproof yarn and its preparation, can solve the problems of complex process, unsmooth sliver making, poor cohesion, etc., and achieve simple process and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

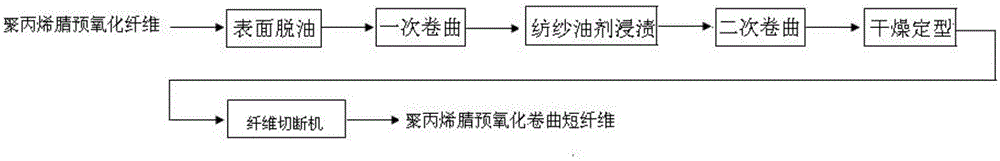

[0033] see figure 2 , the preparation method of high limit oxygen index fireproof yarn, comprises the steps:

[0034] (1) Preparation of polyacrylonitrile preoxidized short fibers

[0035] The polyacrylonitrile preoxidized fiber is subjected to surface deoiling, primary crimping, spinning oil impregnation, secondary crimping, drying and setting, and cutting to obtain polyacrylonitrile preoxidized short fibers with excellent cohesion;

[0036] (2) Preparation of fireproof yarn with high limiting oxygen index

[0037] The polyacrylonitrile preoxidized short fiber prepared in step (1) is blended with the flame-retardant and high-temperature-resistant short fiber to obtain a fireproof yarn with a high limiting oxygen index.

Embodiment 1

[0040] The 320,000-denier polyacrylonitrile preoxidized fiber is deoiled in a 3-meter-long deoiling bath containing 1% sodium dodecylsulfonate surfactant at a temperature of 85°C, and then crimped for the first time to obtain the number of crimps The fiber tape is 3-4 pieces / cm. After dipping in a 3-meter-long mixed oil water bath containing antistatic agent, softener and emulsifier at a temperature of 85 ° C, it is curled for the second time to obtain the number of crimps. It is a fiber tape of 8 pieces / cm, dried and heat-set and cut into 51mm long polyacrylonitrile pre-oxidized fiber for future use. The fiber shows obvious curl and fluffy state.

Embodiment 2

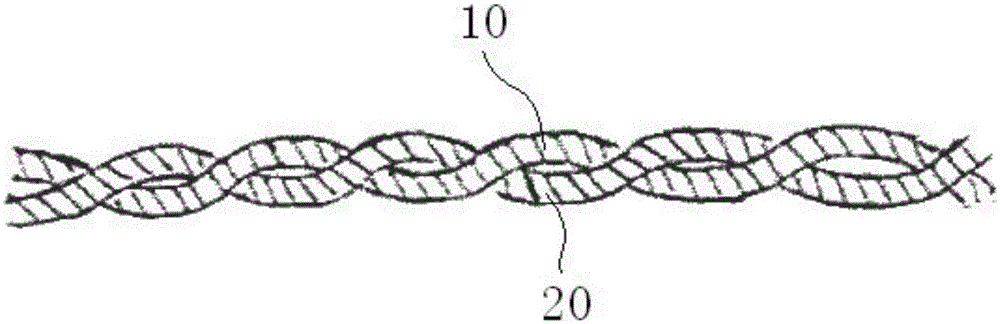

[0042] Take the polyacrylonitrile pre-oxidized staple fiber prepared in Example 1 and para-aramid fiber blended according to the ratio of 85:15, through conventional methods such as blowing, carding, drawing, slubbing, fine spinning, doffing, and twisting, etc. In the ring spinning process, the yarn 40Nm / 2 containing 85% polyacrylonitrile preoxidized fiber is spun, and it is woven into a plain weave fabric. The limiting oxygen index LOI is 42% and the fabric production rate is 95.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com