Copper alloy disc motor clamp piston shockproof dry cleaning machine

A disc motor and copper alloy technology, applied in the field of washing machines, can solve the problems of increasing the diameter of the motor spindle, easy shrinkage, and longer sealing of the motor spindle, and achieve the effects of compact overall size, extended service life and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

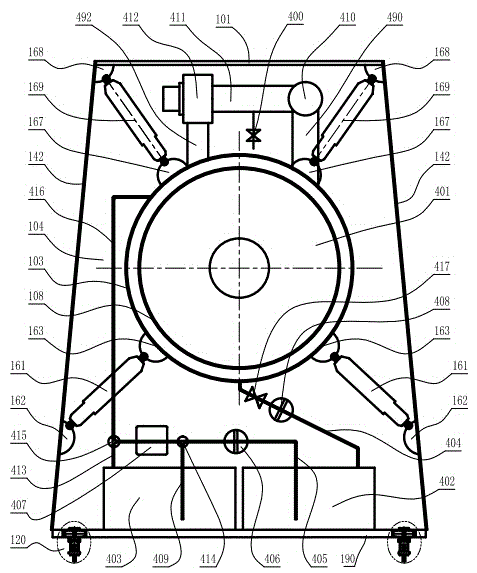

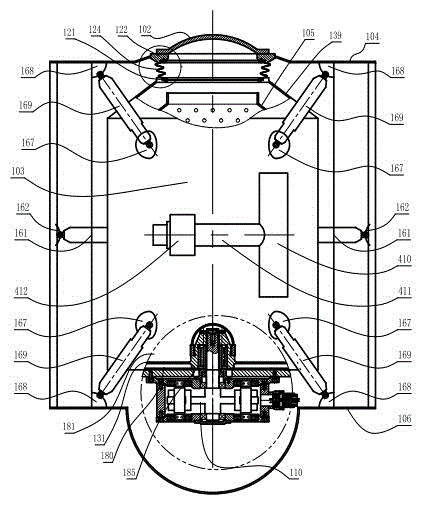

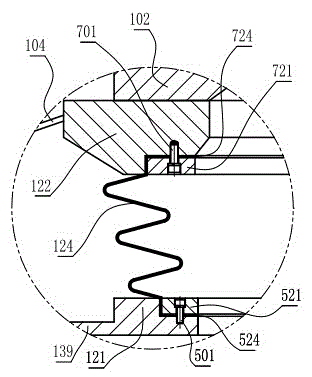

[0046] figure 1 , figure 2 and Figure 10 Middle: Copper alloy disc motor clamp piston shock absorber dry cleaning machine, including a casing 101 and a washing tub 401, and also includes a heat pump drying system, a solvent recovery system, an inner shock absorber assembly, an outer shock absorber wheel set 120 and a disc type Flameproof motor assembly 110; the heat pump drying system includes a gas delivery device 412, a condenser 411, an evaporator 410, and a solvent recovery pipe valve 400, and the air inlet 492 and the air outlet 490 of the heat pump drying system are connected to the washing machine. The tank 401 communicates; the solvent recovery system includes a dirty liquid tank 402 and a clean liquid tank 403; the dirty liquid tank 402 communicates with the washing drum 401 through a first pipeline 404; the dirty liquid tank 402 communicates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com