Pipe type air-air heat exchanger in annular channel

An annular channel, gas heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of poor pressure resistance and thermal expansion adaptability, limited applicable temperature and pressure ranges, and in-tube heat exchangers. The problem of high flow resistance can reduce the flow resistance in the tube, improve the heat transfer effect, and reduce the resistance outside the tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

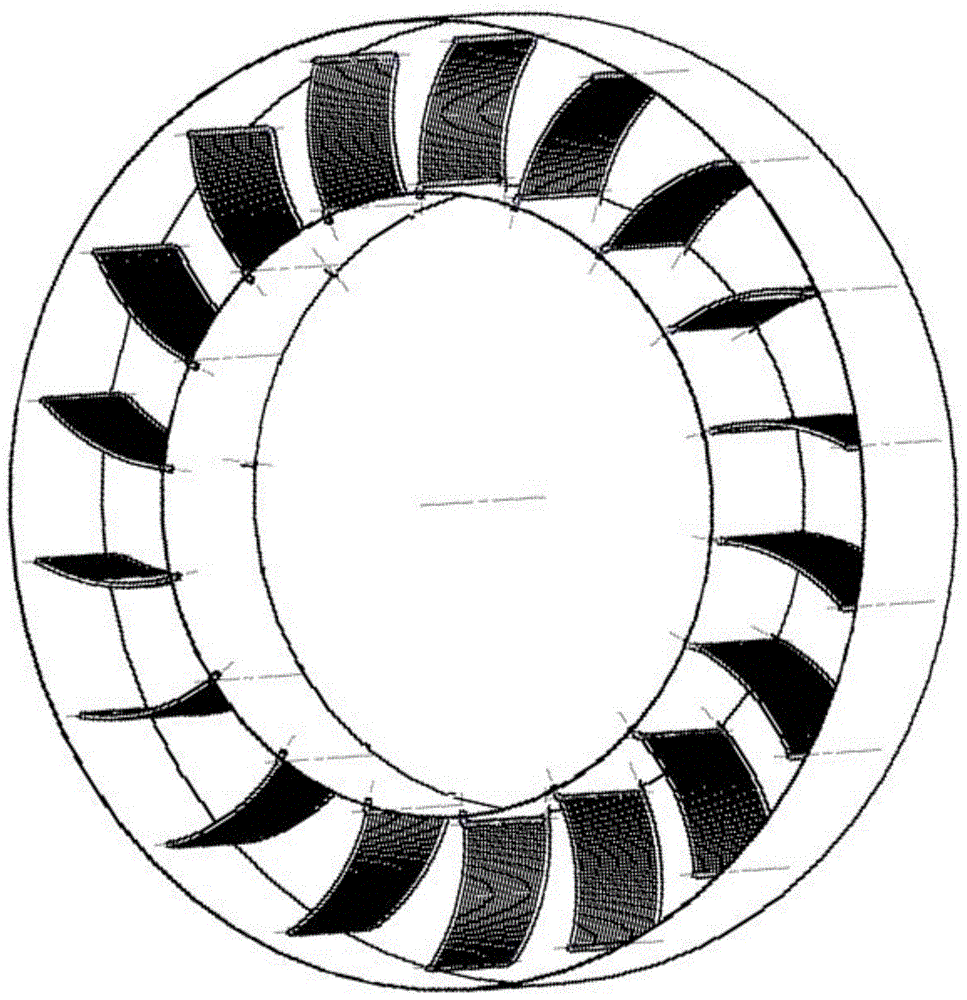

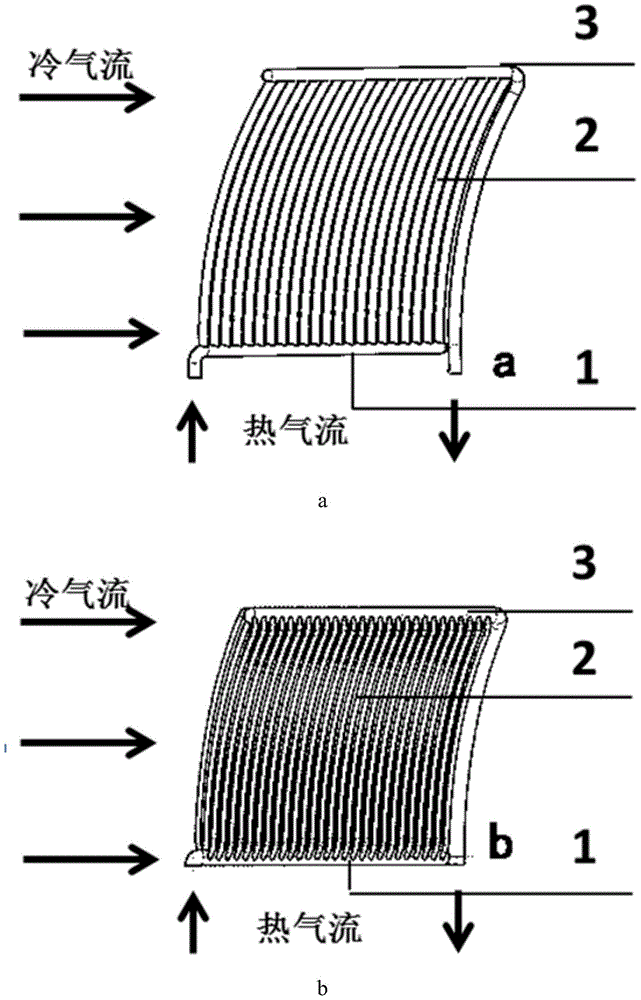

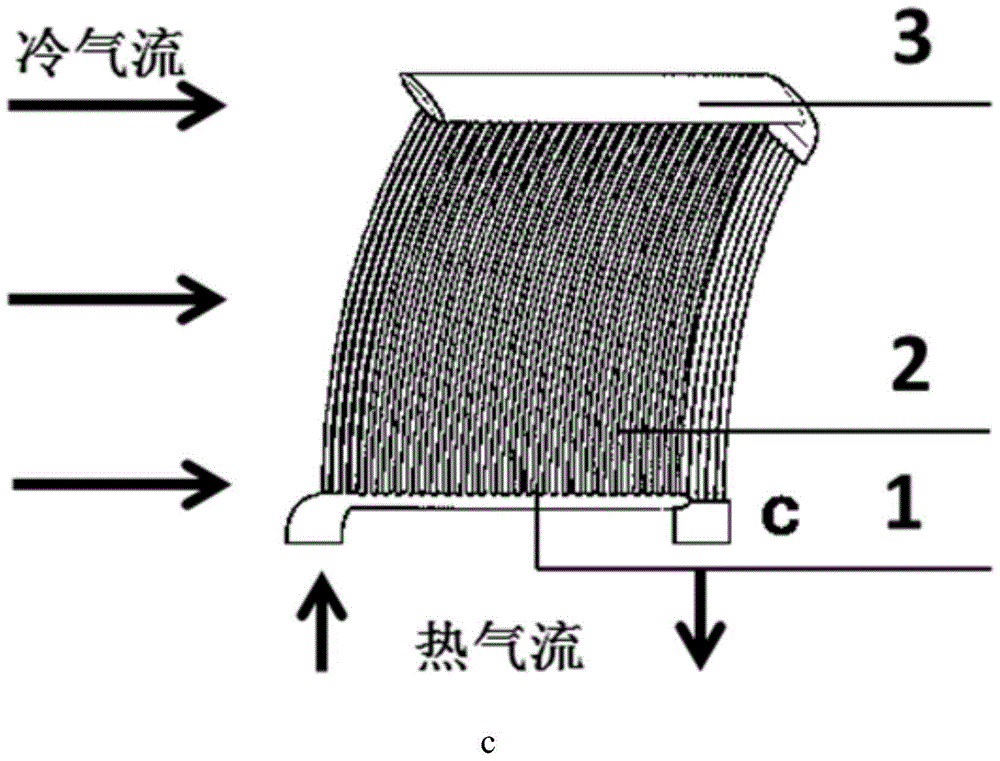

[0025] The present invention is a tube-type gas-gas heat exchanger in an annular channel, such as figure 1 and image 3 As shown, it includes a number of heat exchange units uniformly arranged along the circumferential direction of the annular channel; the cold air flow in the annular duct moves axially, and the heat exchange unit includes the hot air flow out of the collector 1 and the hot air flow arranged along the flow direction of the cold air flow. Inflow air collection pipe 3, and a number of heat exchange tubes 2 connected with hot air flow out of air collection pipe 1 and hot air flow in air collection pipe 3 at both ends; The outlet of the air collecting pipe 1 and the inlet of the hot air flow into the air collecting pipe 3 are located at the same end of the heat exchange unit, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com