Combination cantilever beam probe sensing method and device based on optical fiber exit light detection

A cantilever beam probe and sensing device technology, which is applied to measurement devices, optical devices, mechanical counter/curvature measurement, etc., can solve the problems of low resolution, difficult miniaturization, and complex overall device, and achieves high resolution. , Small size, simple overall device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

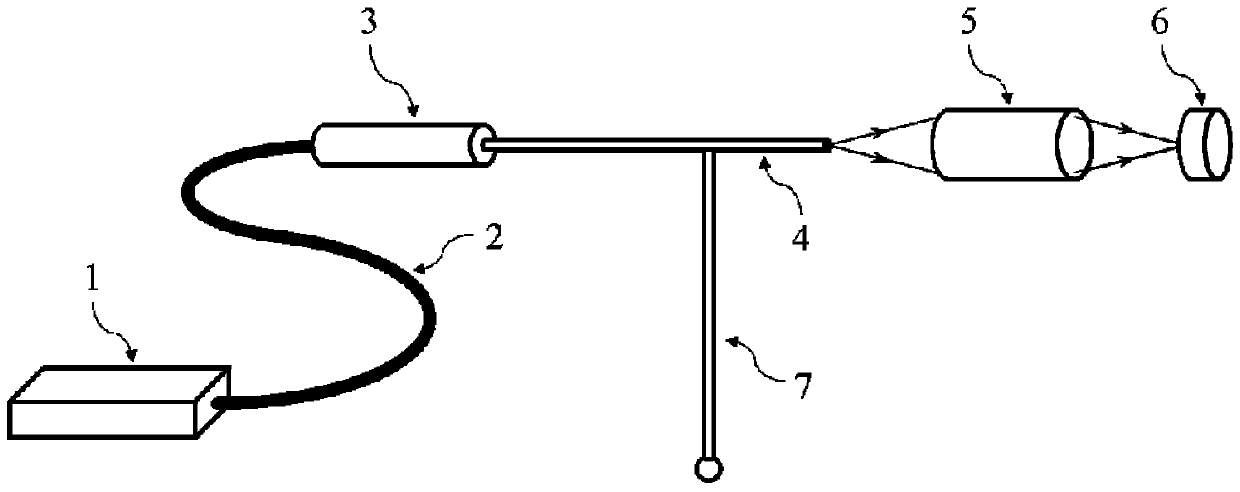

[0023] A combined cantilever beam probe sensing method based on optical fiber exit light detection. The laser beam exits through the optical fiber and then is focused by the lens. The photodetector detects the position of the focused spot. When the probe touches the object, it drives the optical fiber exit end to shift. , causing the position of the spot formed by the focusing of the outgoing light on the photodetector to shift, and the sensing is completed.

[0024] A combined cantilever beam probe sensing device based on optical fiber outgoing light detection. The light emitted by the laser 1 exits through the optical fiber 2, and the optical fiber 2 is fixed by the holder 3 to form a single-end fixed optical fiber cantilever beam 4. A lens 5 and a photodetector 6 are sequentially disposed on the outgoing optical path of the optical fiber 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com