A miniaturized high-isolation ceramic packaging structure

A high-isolation, ceramic packaging technology, which is applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of high crosstalk and coupling effects in transmission channels, limited wiring space, and increased signal loss, etc., to reduce Effects of crosstalk and coupling effects, reduction of influence, and reduction of signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

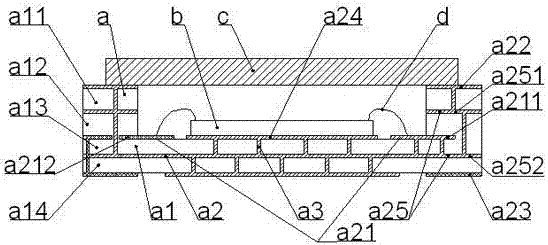

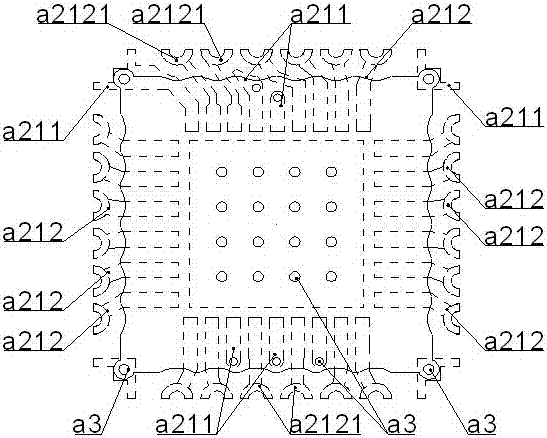

[0024] Embodiment one: if figure 1 As shown, a miniaturized high-isolation ceramic package structure includes a shell a, a chip b, a metal cover c, and a bonding wire d; the shell a is composed of a ceramic layer a1, a metallization layer a2, and an interconnection blind hole a3 The metallization layer a2 is composed of the bonding finger layer a21, the sealing area a22, the connection area a23, the sticky core area a24 and the printed line layer a25; the center of the shell a is provided with a sticky core for placing the chip b area a24; bonding finger layer a21 is provided around the sticky core area a24; the bonding finger layer a21 includes ground bonding finger a211 and signal bonding finger a212, and the ground bonding finger a211 is connected to the The printed wiring layer a25 is connected to the sealing area a22 and the core bonding area a24, and the signal bonding finger a212 is connected to the connection area a23.

[0025] The metallization layer area a2 is base...

Embodiment 2

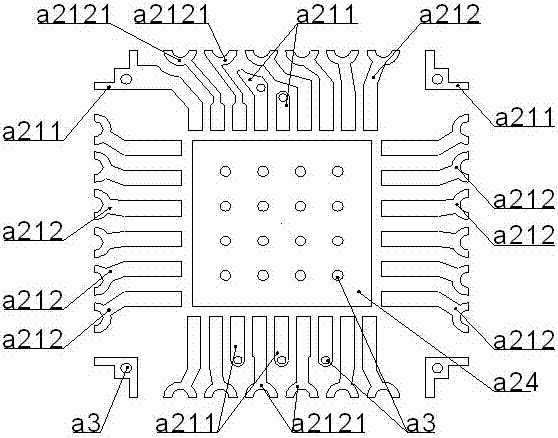

[0031] Embodiment two: if Figure 4 As shown, the difference from the first embodiment is that the core bonding area a24 is in the same layer as the second printed wiring layer a252. Compared with Embodiment 1, the advantage is that the thickness of the shell a can be reduced, but at the same time, the mechanical reliability of the shell a can be reduced. Therefore, this form is mainly used in occasions where the shape of the shell a is small and the thickness of the shell a is required to be high.

Embodiment 3

[0032] Embodiment three: as Figure 5 As shown, the difference from the first embodiment is that the signal bonding finger a212 is interconnected with the connection area a23 through the interconnection blind hole a3 to realize electrical connection. Compared with the first embodiment, since there is no semicircular hole on the edge of the package a, the outer shape of the package a can be further reduced on the premise of ensuring the reliability of the package a, and the miniaturization of the package can be realized. However, it is necessary to reduce the influence of the interconnection blind hole a3 on the mechanical properties of the shell a as much as possible, and the position of the hole needs to be moved inward, which will shorten the wiring length of the bonding finger layer a21 and increase the difficulty of wiring. Therefore, this form is mainly used in occasions where the requirement for isolation is not high, and the requirements for the shape and size of the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com