Lithium ion battery low temperature electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as poor discharge performance and achieve the effect of improving low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

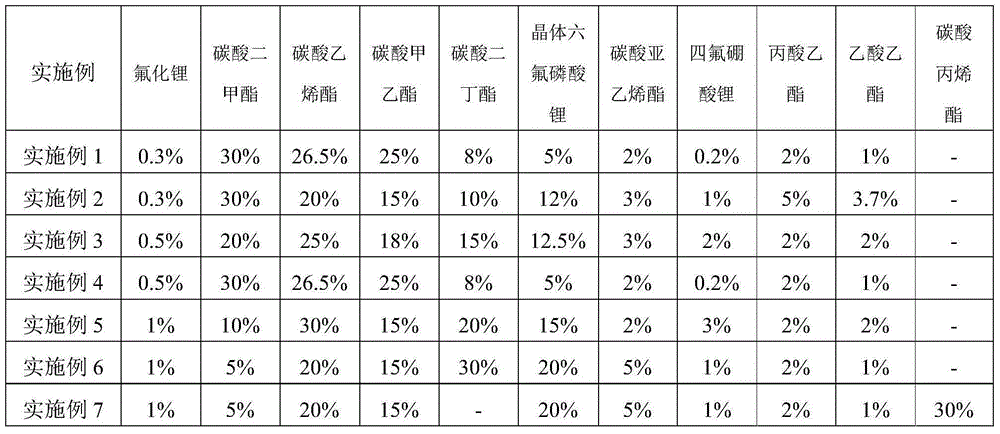

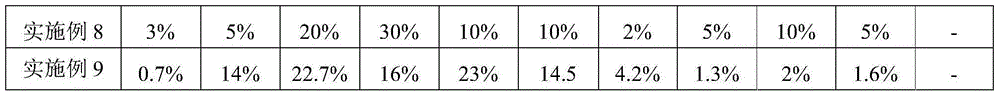

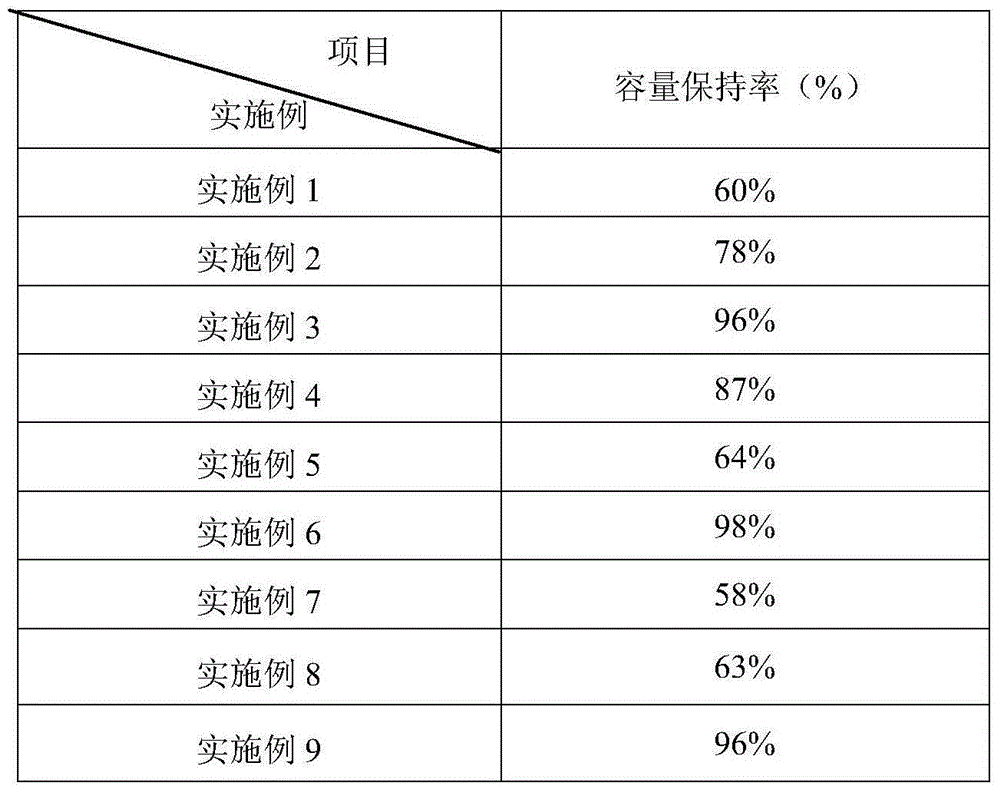

Embodiment 1

[0017] The lithium-ion battery low-temperature electrolyte of this embodiment is composed of the following components in weight percent: lithium hexafluorophosphate 5%, lithium fluoride 0.3%, lithium tetrafluoroborate 0.2%, dimethyl carbonate 30%, ethylene carbonate 26.5%, 25% ethyl methyl carbonate, 8% dibutyl carbonate, 2% vinylene carbonate, 2% ethyl propionate, 1% ethyl acetate.

[0018] In a glove box filled with argon gas, the moisture content is controlled to be <0.1ppm, and the oxygen content is <0.1ppm, and the above-mentioned components are uniformly mixed in proportion to obtain a low-temperature electrolyte for lithium-ion batteries.

[0019] The lithium-ion battery of this embodiment uses the ternary material as the positive electrode and artificial graphite as the negative electrode. The above-mentioned lithium-ion battery low-temperature electrolyte is injected into the battery system, and a lithium-ion battery with a battery capacity of 10Ah is prepared by using...

Embodiment 2

[0021] The lithium-ion battery low-temperature electrolyte of this embodiment is composed of the following components in weight percent: 12% lithium hexafluorophosphate, 0.3% lithium fluoride, 1% lithium tetrafluoroborate, 30% dimethyl carbonate, 20% ethylene carbonate, 15% ethyl methyl carbonate, 10% dibutyl carbonate, 3% vinylene carbonate, 5% ethyl propionate, 3.7% ethyl acetate.

[0022] In a glove box filled with argon gas, the moisture content is controlled to be <0.1ppm, and the oxygen content is <0.1ppm, and the above-mentioned components are uniformly mixed in proportion to obtain a low-temperature electrolyte for lithium-ion batteries.

[0023] In the lithium-ion battery of this embodiment, the ternary material is used as the positive electrode and the artificial graphite is used as the negative electrode. The above-mentioned lithium-ion battery low-temperature electrolyte is injected into the battery system, and a lithium-ion battery with a battery capacity of 10Ah i...

Embodiment 3

[0025] The lithium-ion battery low-temperature electrolyte of the present embodiment is composed of the following components in weight percent: 12.5% lithium hexafluorophosphate, 0.5% lithium fluoride, 2% lithium tetrafluoroborate, 20% dimethyl carbonate, 25% ethylene carbonate, 18% ethyl methyl carbonate, 15% dibutyl carbonate, 3% vinylene carbonate, 2% ethyl propionate, 2% ethyl acetate.

[0026] In a glove box filled with argon gas, the moisture content is controlled to be <0.1ppm, and the oxygen content is <0.1ppm, and the above-mentioned components are uniformly mixed in proportion to obtain a low-temperature electrolyte for lithium-ion batteries.

[0027] In the lithium-ion battery of this embodiment, the ternary material is used as the positive electrode and the artificial graphite is used as the negative electrode. The above-mentioned lithium-ion battery low-temperature electrolyte is injected into the battery system, and a lithium-ion battery with a battery capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com