Current compensation-based unbalance vibration control system for bearingless asynchronous motor

A technology of asynchronous motor and current compensation, applied in motor generator control, electronic commutation motor control, control system, etc., can solve problems such as limited vibration suppression effect, affecting rotor suspension control accuracy, rotor unbalanced vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

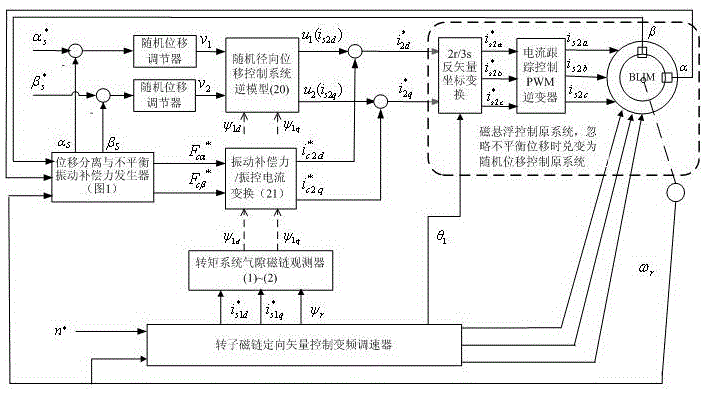

[0037] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

[0038] Core idea of the present invention is:

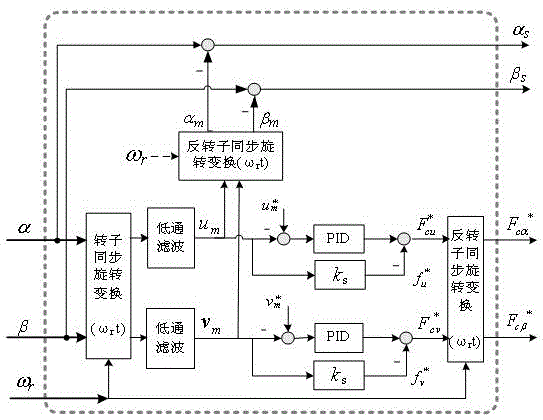

[0039] 1. During the rotation of the bearingless motor rotor, the inevitable rotor mass eccentricity will excite the excitation force in the same direction as the eccentricity; if no vibration control measures are added, under the action of the excitation force, the rotor shaft will The heart produces periodic radial displacement fluctuations or vibrations, that is, unbalanced vibration displacements. The unbalanced vibration displacement signal of the bearingless asynchronous motor rotor is a sinusoidal alternating signal with the same frequency as the rotational speed. Based on this feature, the unbalanced vibration displacement signal can be filtered, tracked and extracted in real time.

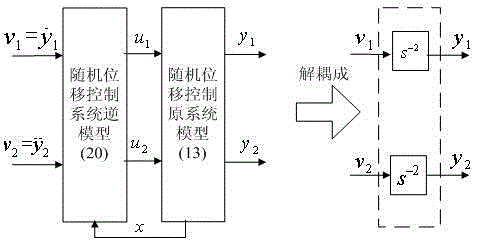

[0040] 2. In order to improve the speed contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com