Desalination method by using sludge to improve topsoil of saline and alkaline land

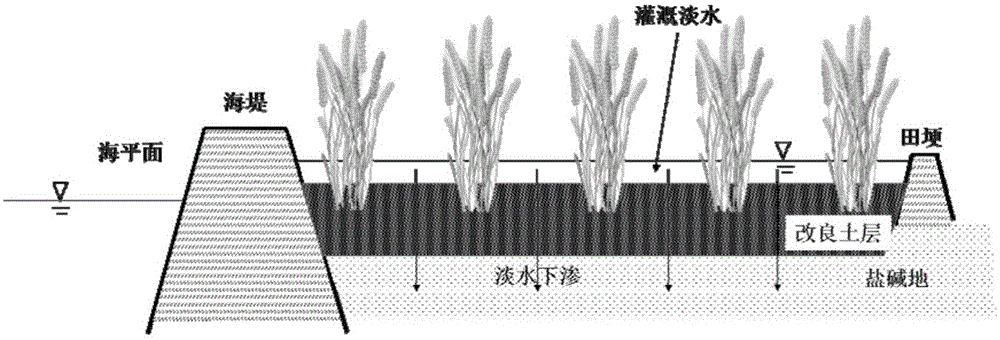

A technology of saline-alkali land and surface soil, which is applied in the field of improving saline-alkali land and using silt to improve saline-alkali surface soil for desalination. It can solve the problems of nutrient deficiency, high consumption, and slow growth of rice, and achieve the reduction of infiltration rate, improvement of soil fertility, and infiltration The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a method for desalinating saline-alkali topsoil by utilizing silt, which includes the following steps:

[0026] (a) Pave silt with a moisture content of 100% on the surface of the saline-alkali soil (the measured N content is about 500 mg / kg, and the P content is about 400 mg / kg), and then the soil and silt within 40 cm of the saline-alkali surface soil are mixed. Mixing (the mass percentage of silt and surface soil is 15%) to form a permeability coefficient of 5.0×10 -5 The mixed area of cm / s, that is, the improved area;

[0027] (b) Surround the mixed area with silt to set up field ridges, irrigate with fresh water, and keep the water depth at 10 cm for 2 months;

[0028] (c) Plant rice in the mixed area, ensure continuous water on the surface of the mixed area during the water demand period of rice growth, the water depth is 15cm, and drain and irrigate water according to the growth characteristics and needs of rice.

Embodiment 2

[0030] The present embodiment provides a method for desalinating saline-alkali topsoil by utilizing silt, which includes the following steps:

[0031] (a) Pave silt with a moisture content of 150% on the surface of the saline-alkali soil (the measured N content is about 600 mg / kg, and the P content is about 500 mg / kg), and then mix the soil and silt within 30 cm of the saline-alkali surface soil Mixing (the mass percentage of silt and surface soil is 20%) to form a permeability coefficient of 1.0×10 -6 cm / s mixing zone;

[0032] (b) Surround the mixed area with silt to set up field ridges, irrigate with fresh water, and keep the water depth at 15 cm for 4 months;

[0033] (c) Plant rice in the mixed area, ensure continuous water on the surface of the mixed area during the water demand period of rice growth, the water depth is 20cm, and drain and irrigate water according to the growth characteristics and needs of rice.

Embodiment 3

[0035] The present embodiment provides a method for desalinating saline-alkali topsoil by utilizing silt, which includes the following steps:

[0036] (a) Pave silt with a water content of 120% on the surface of the saline-alkali soil (the measured N content is about 550 mg / kg, and the P content is about 450 mg / kg), and then mix the soil and silt within 25 cm of the saline-alkali surface soil Mixing (the mass percentage of silt and surface soil is 18%), forming a permeability coefficient of 9.0×10 -5 The mixed area of cm / s, that is, the improved area;

[0037] (b) Surround the mixed area with silt to set up field ridges, irrigate with fresh water, and keep the water depth at 12 cm for 3 months;

[0038] (c) Plant rice in the mixed area, ensure continuous water on the surface of the mixed area during the water demand period of rice growth, the water depth is 18cm, and drain and irrigate water according to the growth characteristics and needs of rice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com