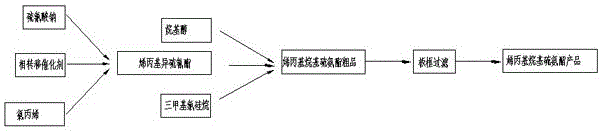

Synthetic process of N-allyl-O- isobutyl thionocarbamate

A synthesis process, allyl technology, applied in the direction of organic chemistry, etc., can solve the problems of low content of allyl isobutyl thiourethane, low conversion rate, etc., and achieve strong reaction activity, improved environmental conditions, and residual amount. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

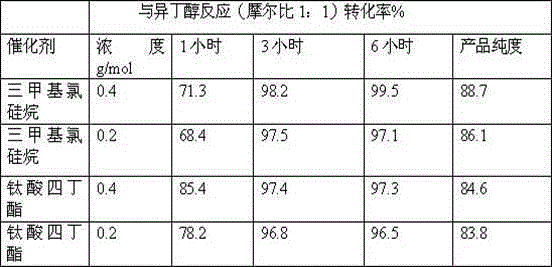

[0020] 0.25 moles of allyl isothiocyanate and 0.5 moles of isobutanol are co-heated to 110°C under normal pressure, and catalyzed by 0.4 g / mole of trimethylchlorosilane or tetrabutyl titanate. The reaction was carried out accordingly, and the conversion was determined by gas chromatography. The reaction results are shown in Table 1:

[0021]

[0022] The data in Table 1 shows that using trimethylchlorosilane as a catalyst compared with tetrabutyl titanate or iron acetylacetonate as a catalyst, the conversion rate has been greatly improved after 3-6 hours of reaction.

Embodiment

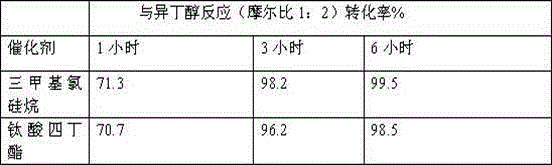

[0024] Carry out the reaction according to Experiment 1, and change the molar ratio of reaction with isobutanol to 1:1, and the test results are shown in Table 2:

[0025]

[0026] The data given in Table 2 shows that when the molar ratio of the reaction with isobutanol is 1:1, using trimethylchlorosilane as the catalyst, the conversion rate and purity of this reaction are relatively high in a short period of time.

Embodiment 3

[0028] The reaction of allylthiocarbamate with propanol

[0029] Except that 0.25 mol of isobutanol was replaced by 0.25 mol of propanol, the experimental procedure was the same as that of experiment 2. Use 0.1 g trimethylchlorosilyl ester (0.4 g / mol allyl thiocyanate). Heating at 110°C for 6 hours yielded N-allyl-O-propyl-thiocarbamate with a conversion rate of 97.2% and a purity of 89.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com