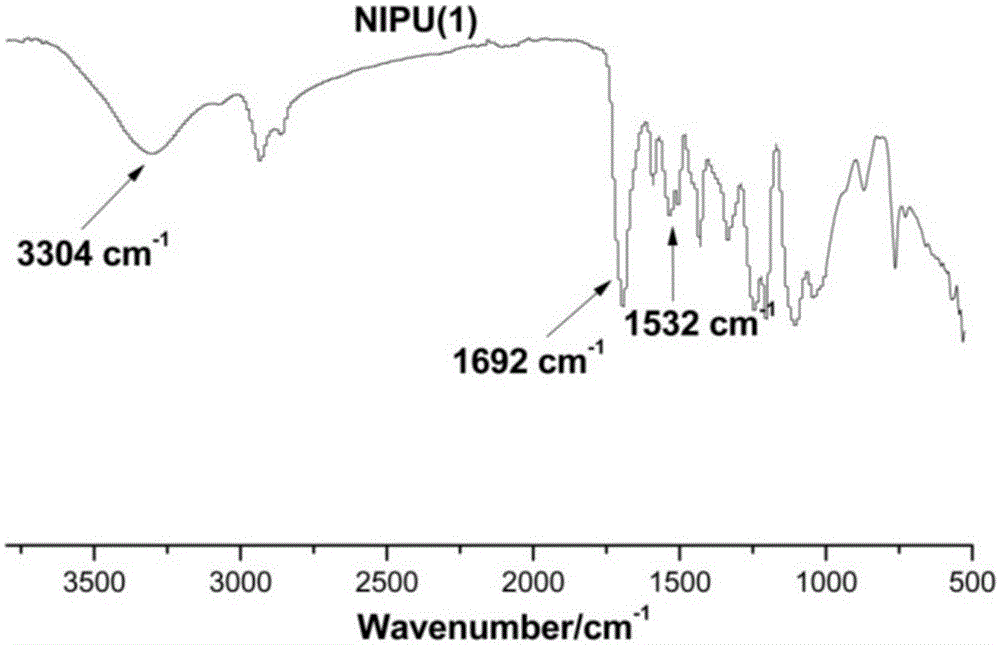

Gallate base cyclic carbonate, non-isocyanate polyurethane and preparation method thereof

An acid-based non-isocyanate and non-isocyanate technology is applied in the field of preparation of biomass-based cyclic carbonates and non-isocyanate polyurethanes, which can solve problems such as human health and environmental hazards, and achieve safe preparation process, high product conversion rate, and high reaction efficiency. mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

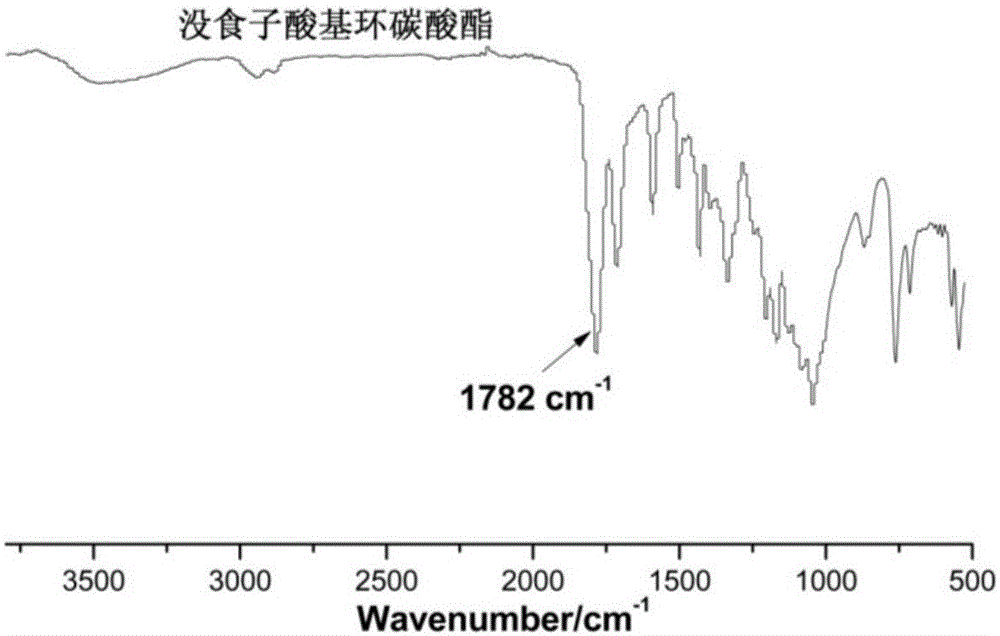

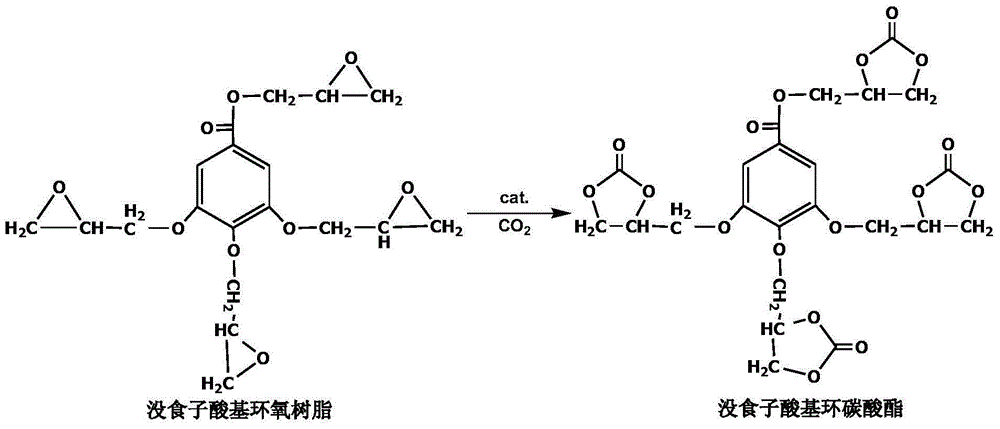

[0033] In a 1L autoclave, add 200g of gallic acid-based epoxy resin, 2g of lithium bromide, 1g of ethylene glycol and 100mL of N-methylpyrrolidone (NMP), raise the temperature to 110°C, and introduce CO 2 To a certain pressure, vent after leak detection. Repeat the operation three times, completely remove the air in the kettle, and introduce CO 2 Keeping the pressure at 2MPa, the reaction was stirred for 9h. After the reaction was completed, the remaining CO in the kettle was evacuated. 2 , The product was poured out while it was hot, the catalyst and NMP were removed by washing with hot water, and the water was distilled off under reduced pressure to obtain a brown solid, namely gallic acid-based cyclocarbonate. The epoxy value of the product was analyzed, and the conversion rate of the epoxy group was 98.9%.

[0034] Product gallic acid base cyclocarbonate in embodiment 1 1 HNMR (500MHz, DMSO-d 6 ,δ):7.01-7.34(m,hydrogensofaromatic); 5.03-5.19(m,methinehydrogensofcyclic...

Embodiment 2

[0038] In a 1L autoclave, add 200g of gallic acid-based epoxy resin, 2g of lithium bromide, 2g of ethylene glycol and 100mL of N,N-dimethylformamide, raise the temperature to 80°C, and introduce CO 2 To a certain pressure, vent after leak detection. Repeat the operation three times, completely remove the air in the kettle, and introduce CO 2 Keep the pressure at 5MPa, and stir the reaction for 15h. After the reaction was completed, the remaining CO in the kettle was evacuated. 2, The product was poured out while it was hot, the catalyst and solvent were removed by washing with hot water, and the water was distilled off under reduced pressure to obtain a brown solid, namely gallic acid-based cyclocarbonate.

Embodiment 3

[0040] In a 1L autoclave, add 200g of gallic acid-based epoxy resin, 2g of lithium bromide, 4g of ethylene glycol and 100mL of N-methylpyrrolidone (NMP), raise the temperature to 130°C, and introduce CO 2 To a certain pressure, vent after leak detection. Repeat the operation three times, completely remove the air in the kettle, and introduce CO 2 Keep the pressure at 0.5MPa, and stir the reaction for 24h. After the reaction was completed, the remaining CO in the kettle was evacuated. 2 , The product was poured out while it was hot, the catalyst and NMP were removed by washing with hot water, and the water was distilled off under reduced pressure to obtain a brown solid, namely gallic acid-based cyclocarbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com