Amine bis(phenolate) tetradentate ligand fourth sub-group metal complex and application thereof

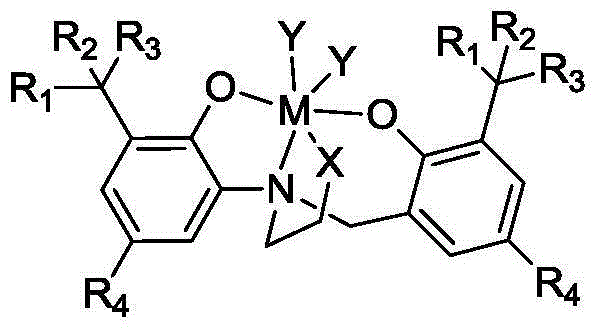

A technology of metal complexes and tetradentate ligands, used in the application of catalytic olefin polymerization, [N,X,O,O]amine bisphenol tetradentate ligands in the field of fourth subgroup metal complexes, which can solve the structural problems Unsuitable and other problems, to achieve the effect of stable structure, high catalytic activity and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

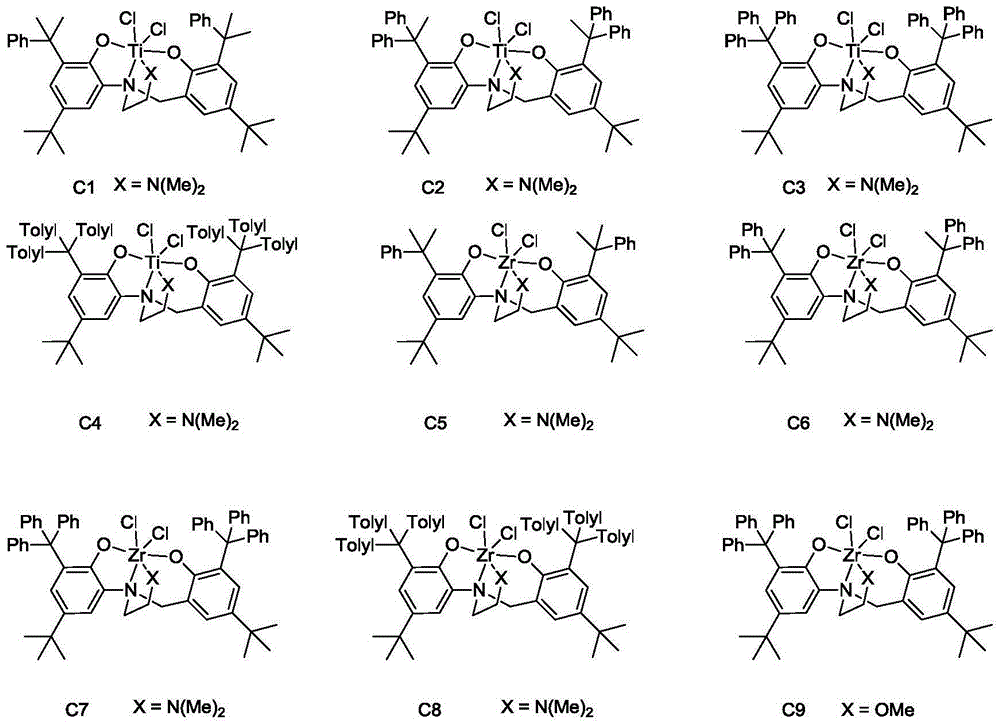

Examples

Embodiment 1

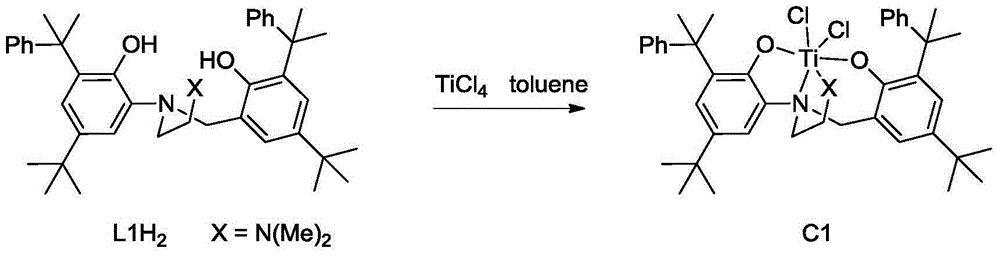

[0019] Example 1 Preparation of Complex C1.

[0020]

[0021] At -78°C, add dropwise 0.4 mL of a toluene solution of titanium tetrachloride with a concentration of 0.825 mol / L to 20 mL of a ligand L1H with a concentration of 0.0165 mol / L 2 In the toluene solution, the mixture was naturally raised to room temperature, stirred for 3 hours, and the solvent was drained to obtain 223 mg of a brick-red metal titanium complex with a yield of 96.2%, which was designated as C1.

Embodiment 2

[0022] Example 2 Preparation of Complex C2.

[0023]

[0024] At -78°C, add 0.4 mL of a toluene solution of titanium tetrachloride with a concentration of 0.825 mol / L dropwise to 20 mL of a ligand L2H with a concentration of 0.0165 mol / L 2 Naturally rise to room temperature in a toluene solution, stir for 3 h, and drain the solvent. That is to say, 276.4 mg of the brick-red compound metal titanium complex was obtained in high yield, with a yield of 95.6%, which was denoted as C2.

Embodiment 3

[0025] Example 3 Preparation of Complex C3.

[0026]

[0027] At -78°C, add 0.4 mL of a toluene solution of titanium tetrachloride with a concentration of 0.825 mol / L dropwise to 20 mL of a ligand L3H with a concentration of 0.0165 mol / L 2 Naturally rise to room temperature in a toluene solution, stir for 3 h, and drain the solvent. 287.8 mg of brick-red metal titanium complex can be obtained with a yield of 87.2%, which is denoted as C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com