Lignite upgrading method

A technology of lignite and raw coal gas, which is applied in coking carbonaceous materials, petroleum industry, coking ovens, etc. It can solve the problems of high dust content in coal gas, high dust removal load, low porous strength of semi-coke, easy to break and mix in, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

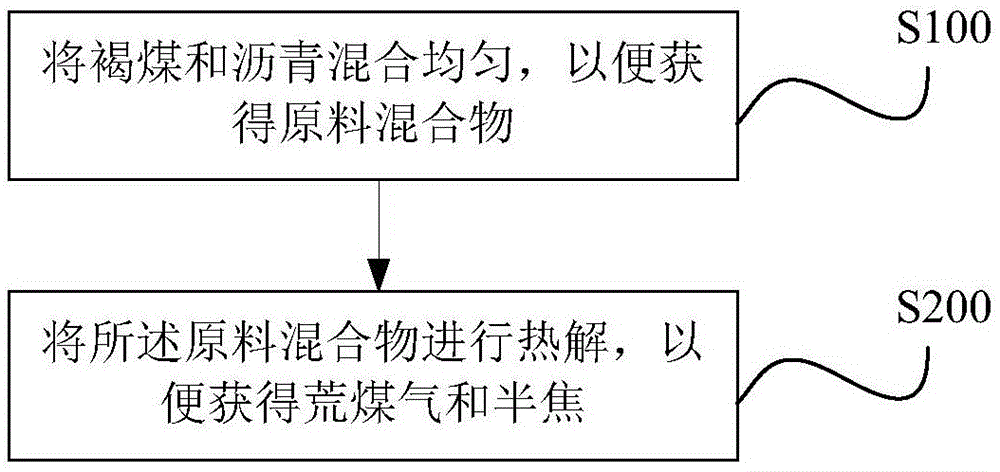

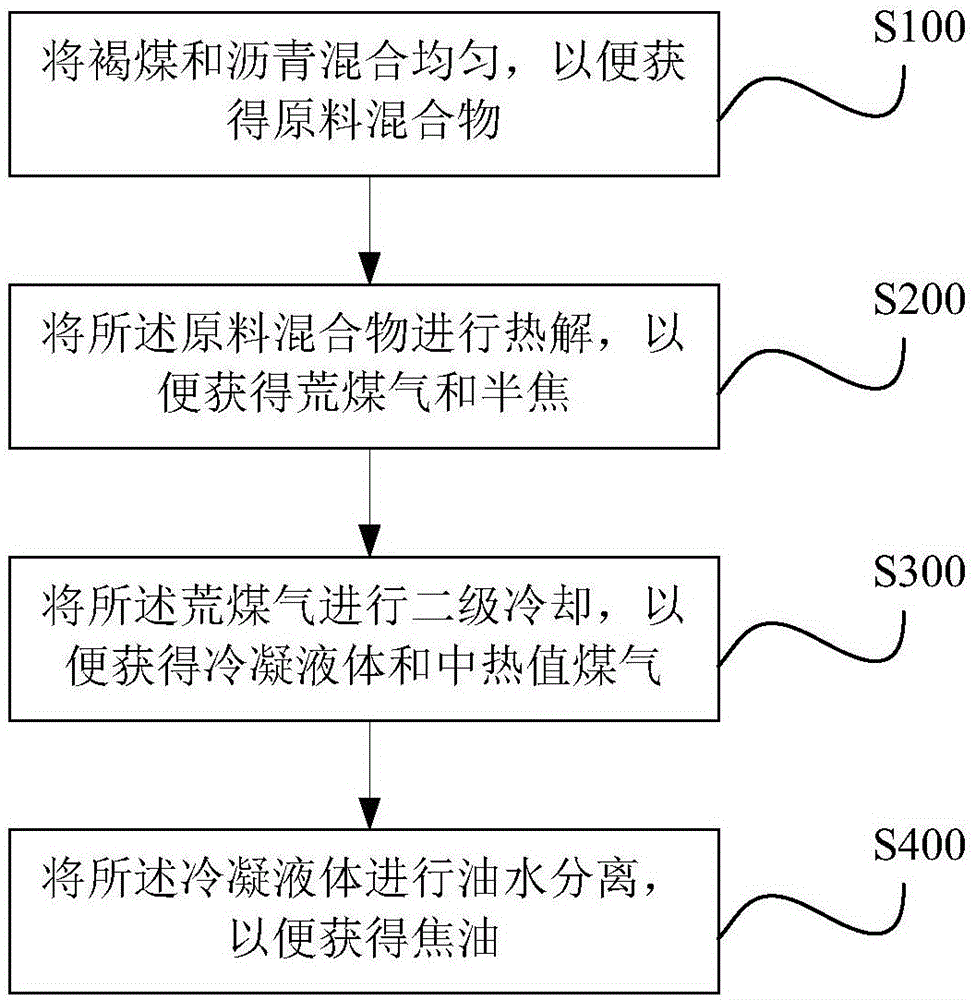

Method used

Image

Examples

Embodiment 1

[0040] In this example, the lignite used in the experiment was selected from Tongliao, Inner Mongolia, and the base moisture was about 40 wt%.

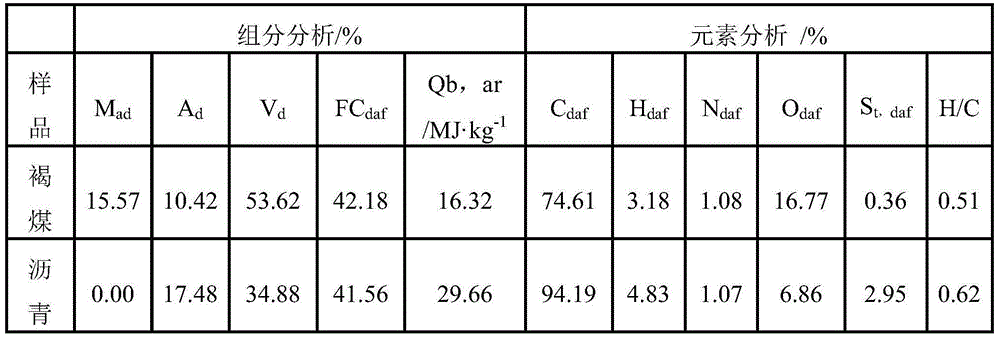

[0041] Table 1 Coal quality indicators

[0042]

[0043] The pyrolysis experiment was carried out using a fixed bed pyrolysis furnace, as follows:

[0044] The lignite is crushed to 6-13mm, and the high-moisture lignite is dried to a moisture content of about 4wt%, and the particle size of the asphalt is crushed to less than 1mm for later use.

[0045] Then, 1kg lignite, 1kg pitch, and 1kg lignite pitch blend (the mass fraction of pitch in the blend is 10%) are placed in a high temperature resistant reaction tube respectively, and the pyrolysis temperature is set to be 550° C., and the holding time is 60min, the heating rate is 10°C / min, and the lignite-bituminous blend is fully mixed with a mixer before entering the furnace.

[0046] The raw coal gas obtained by pyrolysis is indirectly cooled by two stages to obtain condensed li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com