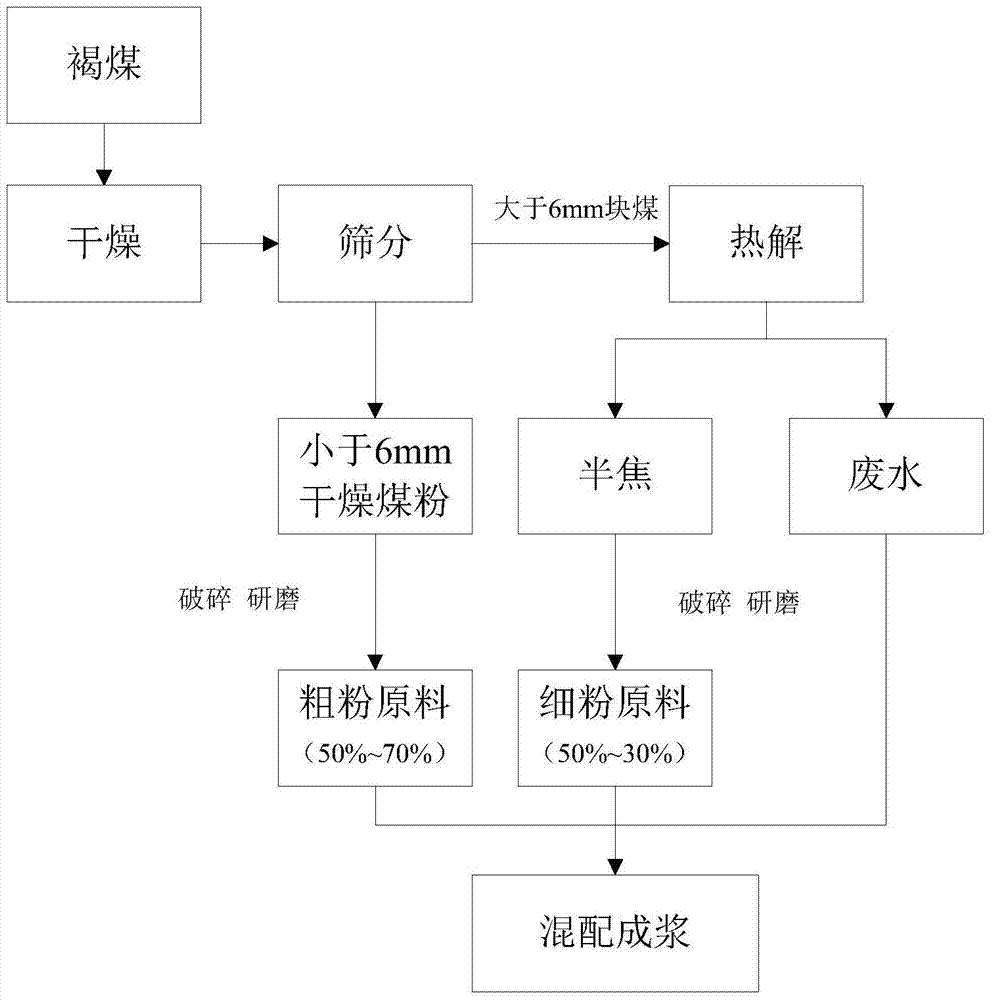

A method of preparing gasified coal-water slurry by combining dry coal powder and semi-coke

A technology for gasifying coal-water slurry and drying coal, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., and can solve the problems of difficult processing, utilization, storage and transportation of dry coal powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The lignite dried at 100-200°C is taken and sieved to obtain a dry powder smaller than 6mm. The dry coal powder smaller than 6mm is further crushed and ground until the particle size smaller than 0.075mm accounts for 34.9%, and its air-dry basis moisture is 9.2%, which is used as raw material for pulping coarse powder. Continue to pyrolyze dry coal blocks larger than 6mm at 500-600°C to obtain semi-coke. The semi-coke is further crushed and ground until the particle size of less than 0.075mm accounts for 74.0%, and its air-drying basis moisture content is 3.5%, which is used as a fine powder raw material for pulping. Take 60% of the above-mentioned coarse powder and 40% of the above-mentioned fine powder according to the mass ratio, add a naphthalene-based dispersant accounting for 1.0% of the total mass of the dry base coarse and fine coal powder, add pyrolysis process wastewater accounting for 32% of the total mass of the coal-water slurry, Stir evenly to prepare a c...

Embodiment 2

[0012] The lignite dried at 180-280°C is taken and sieved to obtain a dry powder smaller than 3mm. The dry coal powder smaller than 3mm is further crushed and ground until the particle size smaller than 0.075mm accounts for 30.2%, and its air-dry basis moisture is 6.1%, which is used as raw material for pulping coarse powder. Continue to pyrolyze dry coal blocks larger than 3mm at 500-700°C to obtain semi-coke. The semi-coke was further crushed and ground until the particle size smaller than 0.075mm accounted for 84.8%, and its air-dried basis moisture content was 4.5%, which was used as a fine powder raw material for pulping. Take 50% of the above-mentioned coarse powder and 50% of the above-mentioned fine powder according to the mass ratio, add a naphthalene-based dispersant accounting for 1.2% of the total mass of the dry base coarse and fine coal powder, add pyrolysis process wastewater accounting for 37% of the total mass of the coal-water slurry, Stir evenly to prepare ...

Embodiment 3

[0014] The lignite is dried at 120-200° C. and then sieved to obtain a dry powder smaller than 6 mm. The dry powder smaller than 6mm was further crushed and ground until the particle size smaller than 0.075mm accounted for 45.1%, and its air-drying basis moisture was 12.2%, which was used as raw material for pulping coarse powder. Continue to pyrolyze dry coal larger than 6mm at 500-700°C to obtain semi-coke. The semi-coke is further crushed and ground, so that the particle size smaller than 0.075mm accounts for 88.3%, and its air-dried basis moisture is 1.0%, which is used as a fine powder raw material for pulping. Take 55% of the above-mentioned coarse powder and 45% of the above-mentioned fine powder according to the mass ratio, add a naphthalene-based dispersant accounting for 1.2% of the total mass of the dry base coarse and fine coal powder, add new water accounting for 35% of the total mass of the coal-water slurry, and stir evenly , the prepared concentration is 59.2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com