Internal combustion engine cylinder anti-eccentric wear device

An internal combustion engine cylinder and anti-eccentric wear technology, which is applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of reduced heat energy utilization rate of internal combustion engines, damage to the inner wall of the cylinder or piston, and uneven friction, so as to eliminate the phenomenon of partial wear , easy processing, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

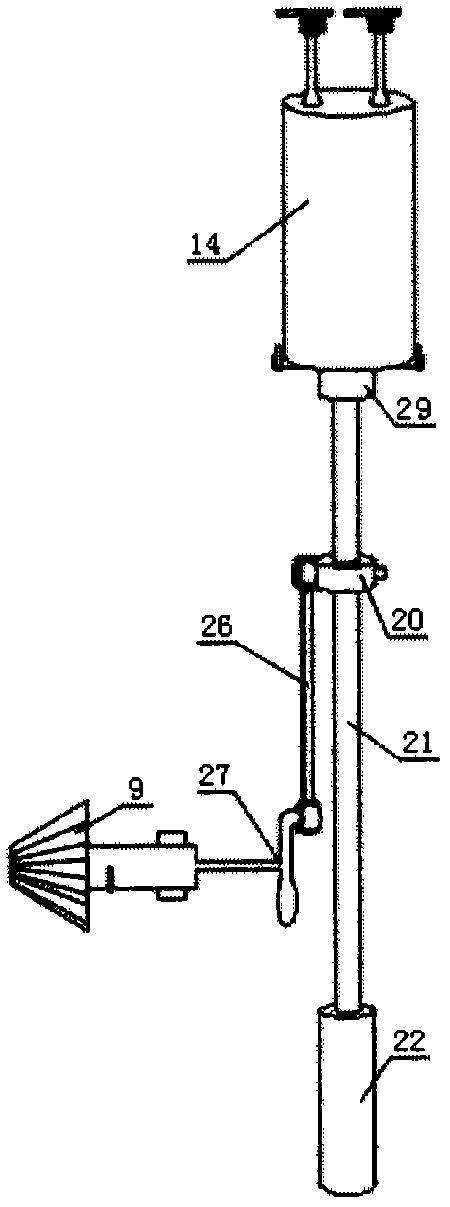

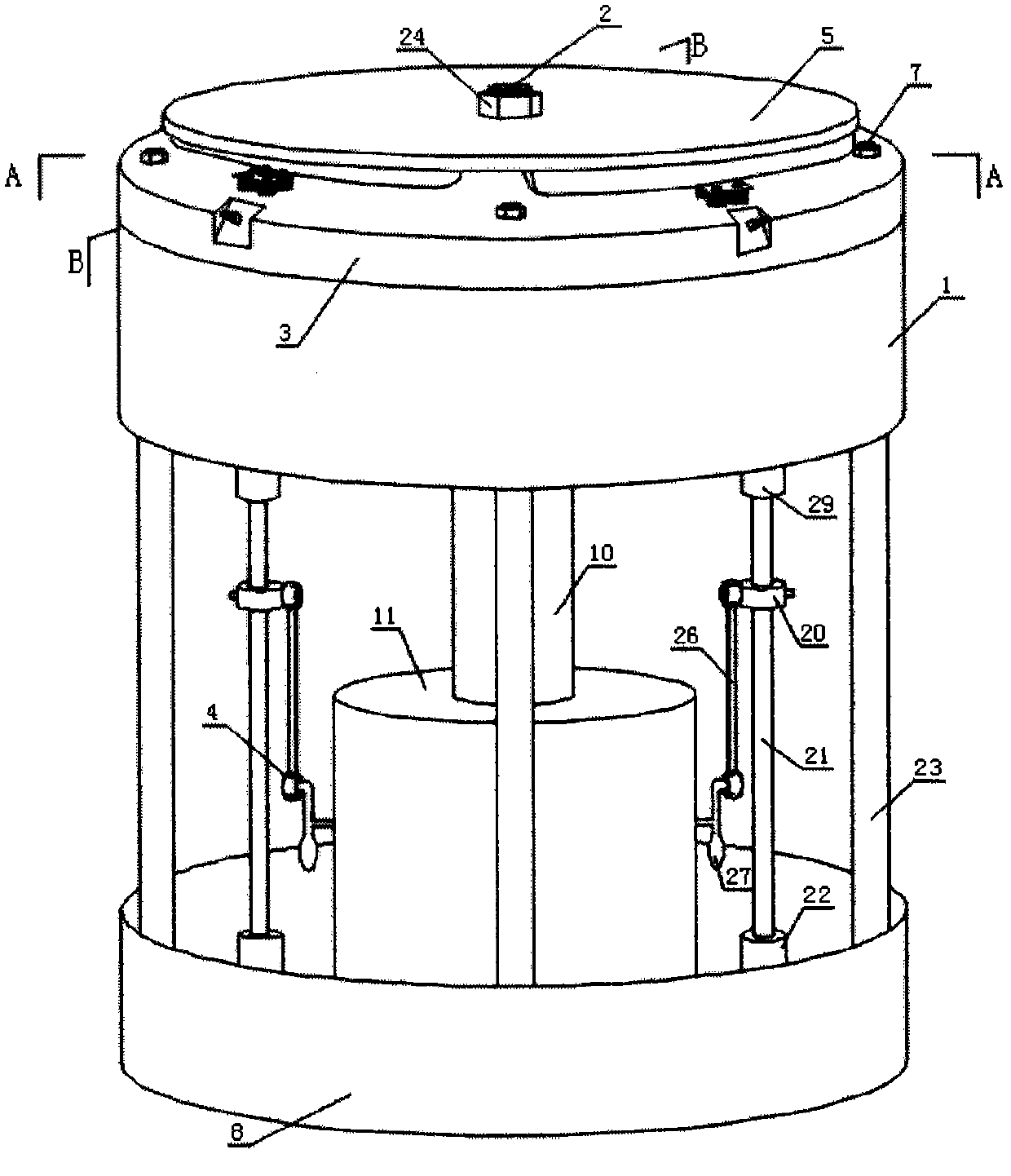

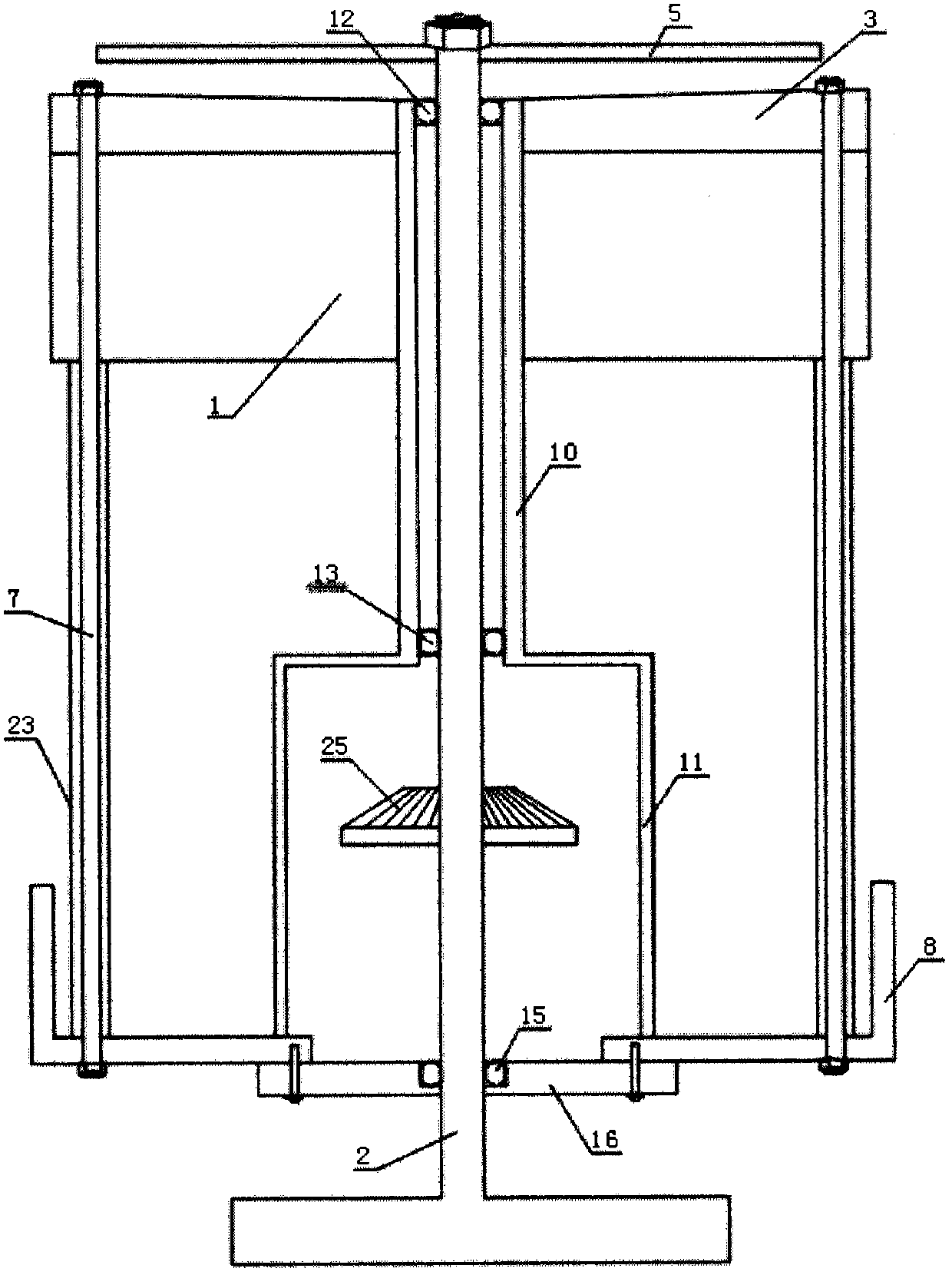

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the eccentric wear prevention device for the cylinder of an internal combustion engine of this embodiment includes a cylinder block 1, an output power shaft 2, a cylinder head 3, a crankshaft connecting rod device 4, a cam disc 5, and a lubricating device 6, and the cylinder block 1 is provided The cylinder bore 18 and the piston 28, the crankshaft connecting rod device 4 includes a crankshaft 27, a connecting rod 26 and a crankshaft gear 9, and the lubricating device 6 is provided with a lubricating oil tank 8 bottom plate. The internal combustion engine cylinder anti-eccentric wear device is provided with an upper sleeve 29, a lower sleeve 22 and a piston guide rod 21. The upper sleeve 29 is fixed to the lower end of the cylinder bore 18 of the cylinder block 1, and the lower sleeve 22 is fixed to the inner bottom of the lubricating oil tank 8. , The two ends of the piston guide rod 21 are respectively slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com