2D layered structure V2C electrode material and preparation method and application

An electrode material, two-dimensional layered technology, applied in the field of electrochemical materials, to achieve high specific capacitance, good electrochemical stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

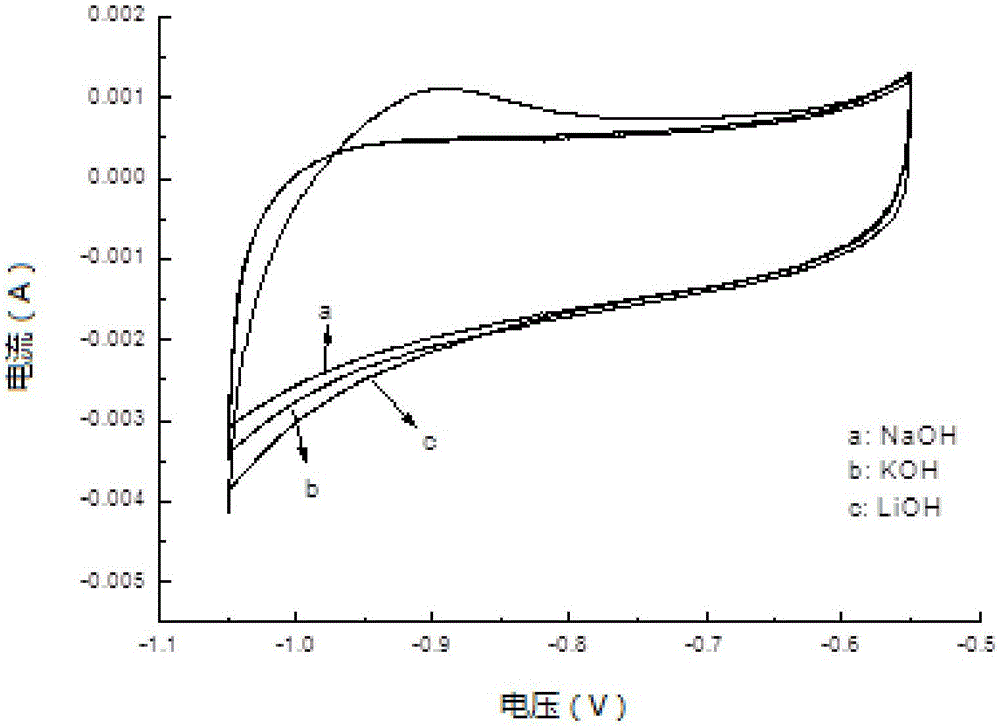

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment two-dimensional layered structure V 2 The C electrode material is prepared by the following steps:

[0032] (1) In an inert gas atmosphere, add vanadium powder, aluminum powder and graphite powder into the ball milling tank at a material ratio of 2:1.3:1. The ball-to-material ratio in the ball milling tank is 1:1. 6h, prepare the precursor mixture;

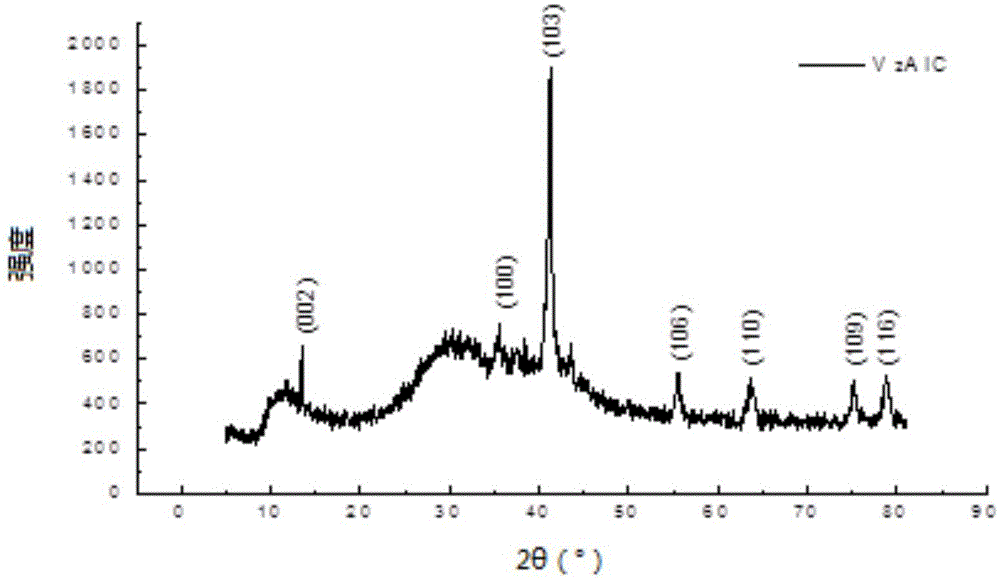

[0033] (2) Transfer the precursor mixture to a tube furnace, pass in an inert gas, raise the temperature of the tube furnace to 1500 °C at 5 °C / min, and treat at a constant temperature for 4 hours to obtain a two-dimensional carbide crystal V 2 AlC;

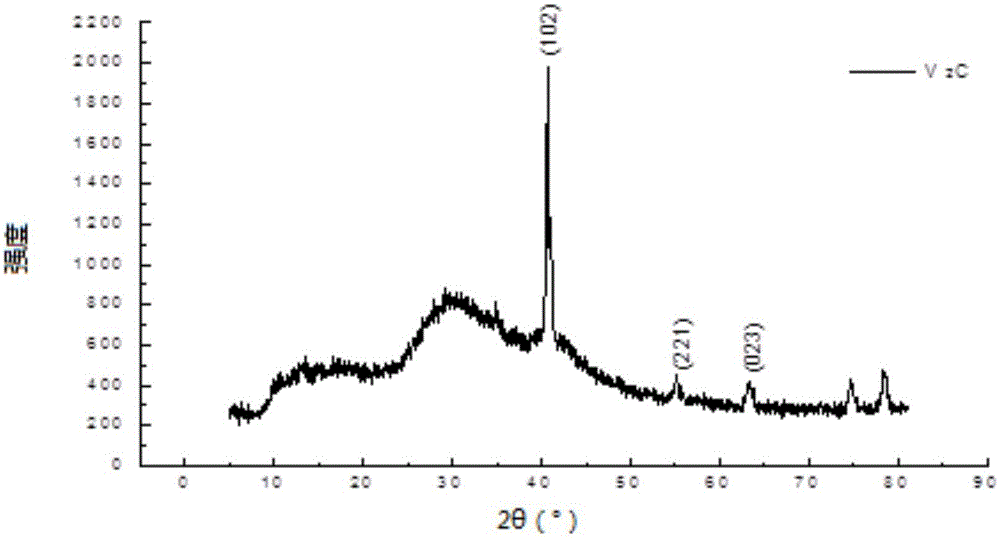

[0034] (3) The two-dimensional carbide crystal V 2 AlC is placed in a HF solution with a mass fraction of 20%, etched for 90 hours, filtered, washed, and dried to obtain the two-dimensional layered structure V 2 C electrode material.

[0035] Wherein, the purity of vanadium powder, aluminum powder and graphite powder are analytical pure, and graphit...

Embodiment 2

[0044] The present embodiment two-dimensional layered structure V 2 The C electrode material is prepared by the following steps:

[0045] (1) In an inert gas atmosphere, add vanadium powder, aluminum powder and graphite powder into the ball milling tank at a mass ratio of 2:1.5:1, and the ball-to-material ratio in the ball milling tank is 1.5:1 , ball milling and mixing for 3 hours to prepare the precursor mixture;

[0046] (2) Transfer the precursor mixture to a tube furnace, pass in an inert gas, raise the temperature of the tube furnace to 1600 °C at 4 °C / min, and treat at a constant temperature for 2 hours to obtain a two-dimensional carbide crystal V 2 AlC;

[0047] (3) The two-dimensional carbide crystal V 2 AlC is placed in a HF solution with a mass fraction of 10%, etched for 120 hours, filtered, washed, and dried to obtain the two-dimensional layered structure V 2 C electrode material.

[0048] Wherein, the purity of vanadium powder, aluminum powder and graphite ...

Embodiment 3

[0052] The present embodiment two-dimensional layered structure V 2 The C electrode material is prepared by the following steps:

[0053] (1) In an inert gas atmosphere, add vanadium powder, aluminum powder and graphite powder into the ball milling tank at a material ratio of 2:1:1. The ball-to-material ratio in the ball milling tank is 2:1. 4h, prepare the precursor mixture;

[0054] (2) Transfer the precursor mixture to a tube furnace, pass in an inert gas, raise the temperature of the tube furnace to 1300 °C at 6 °C / min, and treat at a constant temperature for 5 hours to obtain a two-dimensional carbide crystal V 2 AlC;

[0055] (3) The two-dimensional carbide crystal V 2 AlC is placed in a HF solution with a mass fraction of 30%, etched for 60 hours, filtered, washed, and dried to obtain the two-dimensional layered structure V 2 C electrode material.

[0056] Wherein, the purity of vanadium powder, aluminum powder and graphite powder are analytical pure, and graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com