High-specific-energy super capacitor negative pole sheet and preparation method thereof

A technology for supercapacitors and negative plates, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of low specific energy of supercapacitors, achieve good power characteristics, increase specific energy, and high specific energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, put the binder in the solvent, stir well until it dissolves evenly;

[0031] Step 2, pour the conductive agent into the binder solution and stir thoroughly;

[0032] Step 3, pour the active material powder into the solution in the above step 2, and stir until a uniform slurry is formed; the active material is a mixture of activated carbon, natural graphite, and mesophase carbon microspheres, wherein the amount of activated carbon is based on the active material The mass percentage content is 5%, and the specific surface area is 1000~2000m 2 / g, the particle size is 5~20μm, and the mass ratio of natural graphite to mesophase carbon microspheres is 1:1;

[0033] Step 4, evenly coat the slurry on the current collector, and after drying, press to form an electrode sheet, which is the negative electrode sheet of the high specific energy supercapacitor of the present invention; the current collector is copper foil with a thickness of 10~ 15 μm.

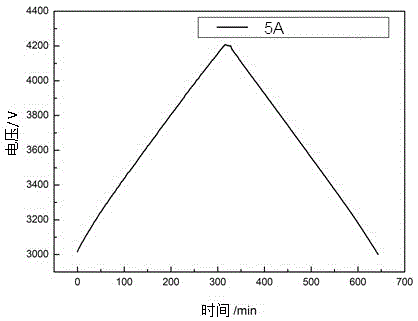

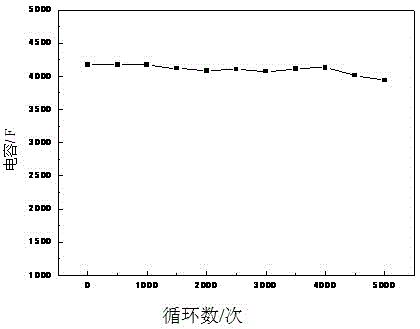

[0034] Use the neg...

Embodiment 2

[0039] Step 1, put the binder in the solvent, stir well until it dissolves evenly;

[0040] Step 2, pour the conductive agent into the binder solution and stir thoroughly;

[0041] Step 3, pour the active material powder into the solution of the above step 2, fully stir until a uniform slurry is formed; the active material is a mixture of activated carbon, natural graphite, and hard carbon, wherein the amount of activated carbon is based on the mass of the active material. The component content is 20%, and the specific surface area is 1000~2000m 2 / g, the particle size is 5~20μm, and the mass ratio of natural graphite to hard carbon is 1:1;

[0042] Step 4, evenly coat the slurry on the current collector, and after drying, press to form an electrode sheet, which is the negative electrode sheet of the high specific energy supercapacitor of the present invention; the current collector is copper foil with a thickness of 10~ 15 μm.

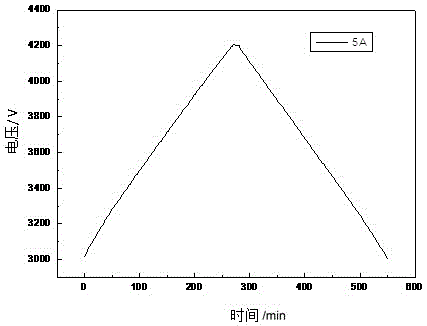

[0043] The same method as in Example 1 is us...

Embodiment 3

[0045] Step 1, put the binder in the solvent, stir well until it dissolves evenly;

[0046] Step 2, pour the conductive agent into the binder solution and stir thoroughly;

[0047]Step 3, pouring the active material powder into the solution of the above step 2, fully stirring until a uniform slurry is formed; the active material is a mixture of activated carbon and natural graphite, wherein the amount of activated carbon is based on the mass percentage of the active material 50%, the specific surface area is 1000~2000m 2 / g, the particle size is 5~20μm;

[0048] Step 4, evenly coat the slurry on the current collector, and after drying, press to form an electrode sheet, which is the negative electrode sheet of the high specific energy supercapacitor of the present invention; the current collector is copper foil with a thickness of 10~ 15 μm.

[0049] Using the same method as in Example 1 to assemble a supercapacitor for testing, the test results show that the charge and disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com