Optical fiber drawing method and optical fiber drawing device

An optical fiber and wire drawing technology, which is applied in the field of optical fiber drawing and optical fiber drawing devices, can solve the problems of glass optical fiber diameter changes and changes, and achieve the effects of reducing space volume, reducing pressure changes in the furnace, and stabilizing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

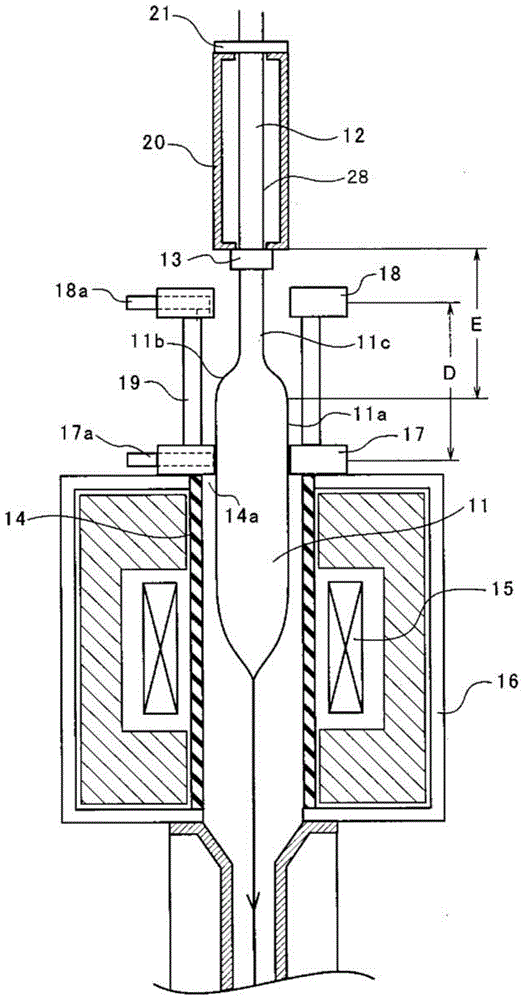

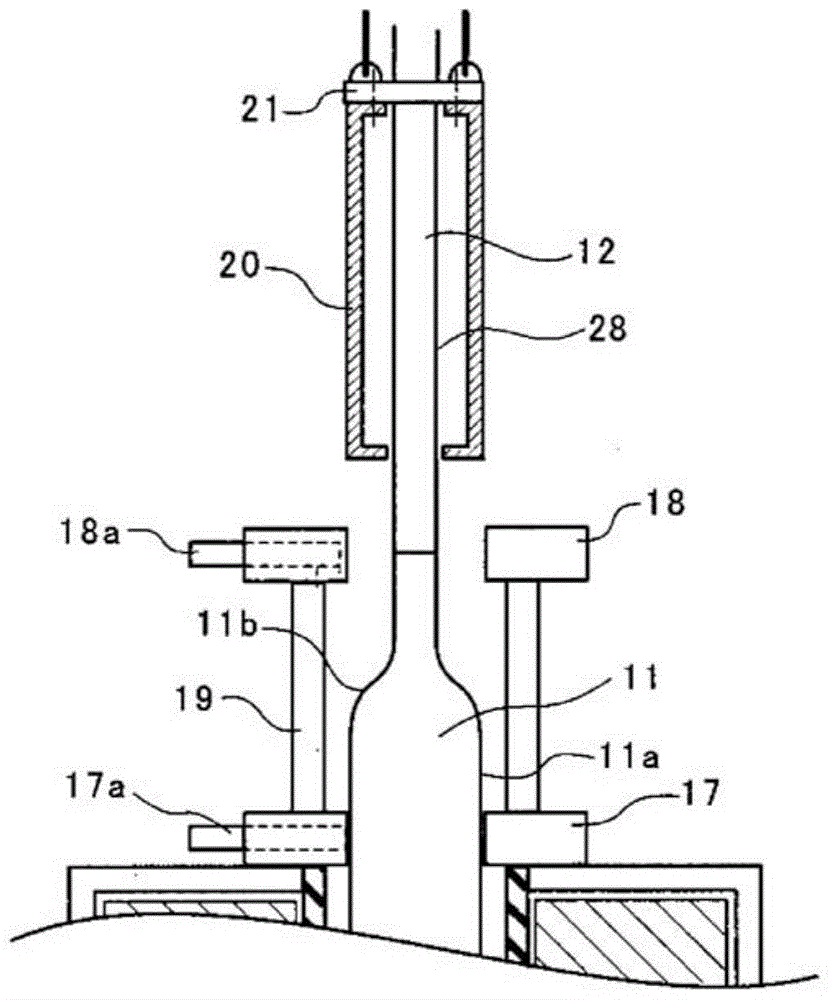

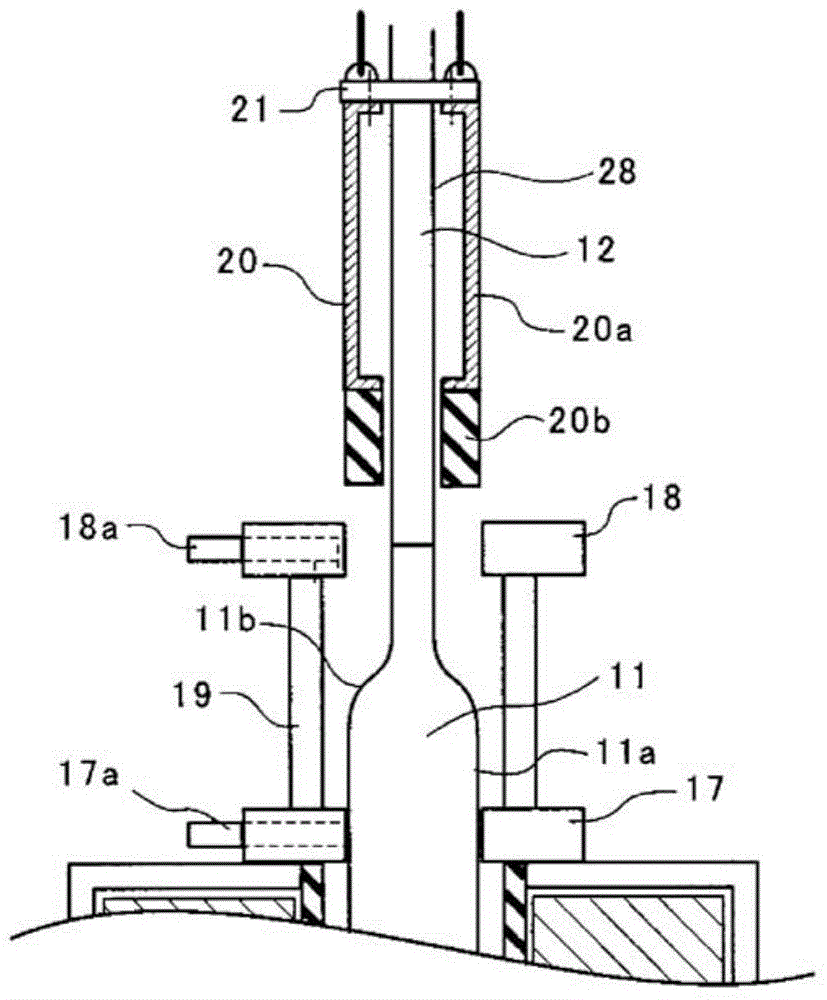

[0030] Next, specific examples of the optical fiber drawing method and the optical fiber drawing apparatus according to the embodiment of the present invention will be described with reference to the drawings.

[0031] In addition, although a resistance furnace in which a core tube is heated by a heater is described below as an example, the present invention can also be applied to an induction furnace in which a core tube is heated by induction by applying a high-frequency power supply to a coil.

[0032] exist figure 1 ~Among Fig. 4, 11 represents glass base material, 11a represents straight body portion, 11b represents taper portion, 11c represents diameter reducing portion, 12 represents assembly rod, 13 represents connecting member, 14 represents furnace tube, 15 represents heater, 16 17 denotes the first sealing part, 17a denotes the gas supply port, 18 denotes the second sealing part, 18a denotes the gas supply port, 19 denotes the upper chamber, 20 denotes the sleeve me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com