Preservation method of egg liquid

A fresh-keeping method and egg liquid technology, applied in the field of egg product processing, can solve the problems of high temperature sterilization, protein variability, etc., and achieve the effect suitable for storage, transportation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The fresh-keeping method of albumen liquid, the steps are:

[0031] Take the eggs within 30 days, wash, test, select, sterilize and air-dry with ultraviolet light, beat the eggs to separate 5kg of protein liquid; adjust the pH value to 7.0 with citric acid, add 500mg of Nisin, and stir until completely dissolved. Then use a Sanovo pasteurizer to sterilize the obtained protein solution at 56° C. for 200 seconds under normal pressure, and aseptically fill it to obtain a finished product.

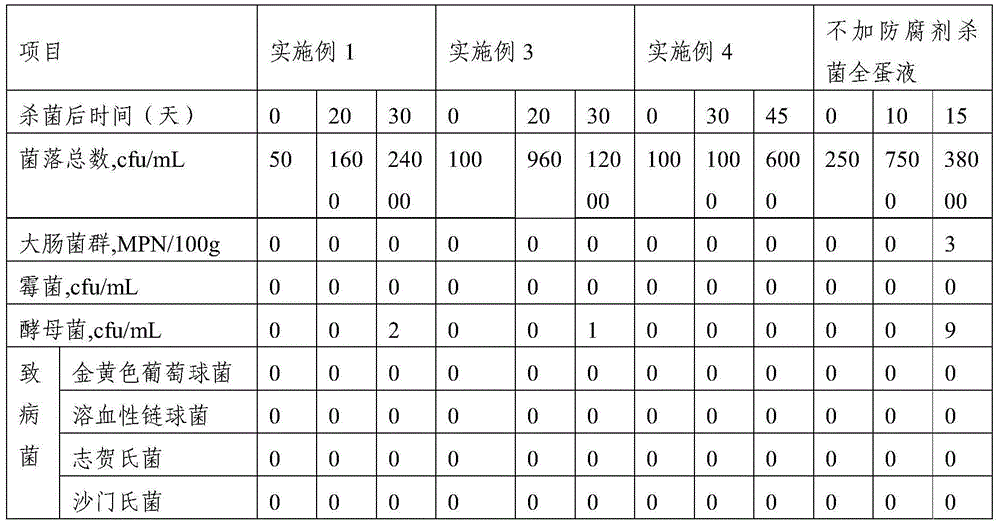

[0032] The prepared egg liquid was tested by GB-T4789.2-2010 food microbiology test for the determination of the total number of colonies, GB-T4789.4-2008 food hygiene microbiology test Salmonella detection and GB-T4789.38-2010 food hygiene microbiology test Escherichia coli count .

Embodiment 2

[0034] The fresh-keeping method of albumen liquid, the steps are:

[0035] Take the eggs within 30 days, wash, test, select, sterilize and air-dry with ultraviolet rays, beat the eggs to separate 5kg of protein liquid; cool to 4°C, adjust the pH value to 7.0 with citric acid, add 500mg of Nisin and 1.5g of potassium sorbate, and stir until completely dissolve. Then use a Sanovo pasteurizer to sterilize the obtained protein solution at 56° C. for 200 seconds under normal pressure, and aseptically fill it to obtain a finished product.

[0036] The prepared egg liquid was tested by GB-T4789.2-2010 food microbiology test for the determination of the total number of colonies, GB-T4789.4-2008 food hygiene microbiology test Salmonella detection and GB-T4789.38-2010 food hygiene microbiology test Escherichia coli count . Table 1 is the comparison of embodiment 1 and embodiment 2 anticorrosion effect. It can be seen from the experimental results that the combination of the two prese...

Embodiment 3

[0040] The fresh-keeping method of whole egg liquid, the steps are:

[0041] Take the eggs within 30 days, wash, test, select, sterilize and air-dry with ultraviolet rays, beat the eggs to separate 5kg of whole egg liquid; cool to 4°C, adjust the pH value to 7.0 with sodium lactate, add 500mg of Nisin, and stir until completely dissolved. Homogenize once under 0.6Mpa. The obtained whole egg liquid was sterilized at 68°C for 180s under normal pressure with a Sanovo pasteurizer, and aseptically filled to obtain a finished product.

[0042] The prepared whole egg liquid was tested by GB-T4789.2-2010 food microbiology test for the determination of the total number of colonies, GB-T4789.4-2008 food hygiene microbiology test Salmonella detection and GB-T4789.38-2010 food hygiene microbiology test Escherichia coli count.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com