Method for online detection of longitudinal tear fault of conveyor belt

A technology of longitudinal tearing and detection method, applied in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of poor accuracy and reliability, easy damage, etc., to achieve high accuracy, easy fault detection, The effect of improving reliability and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and embodiments.

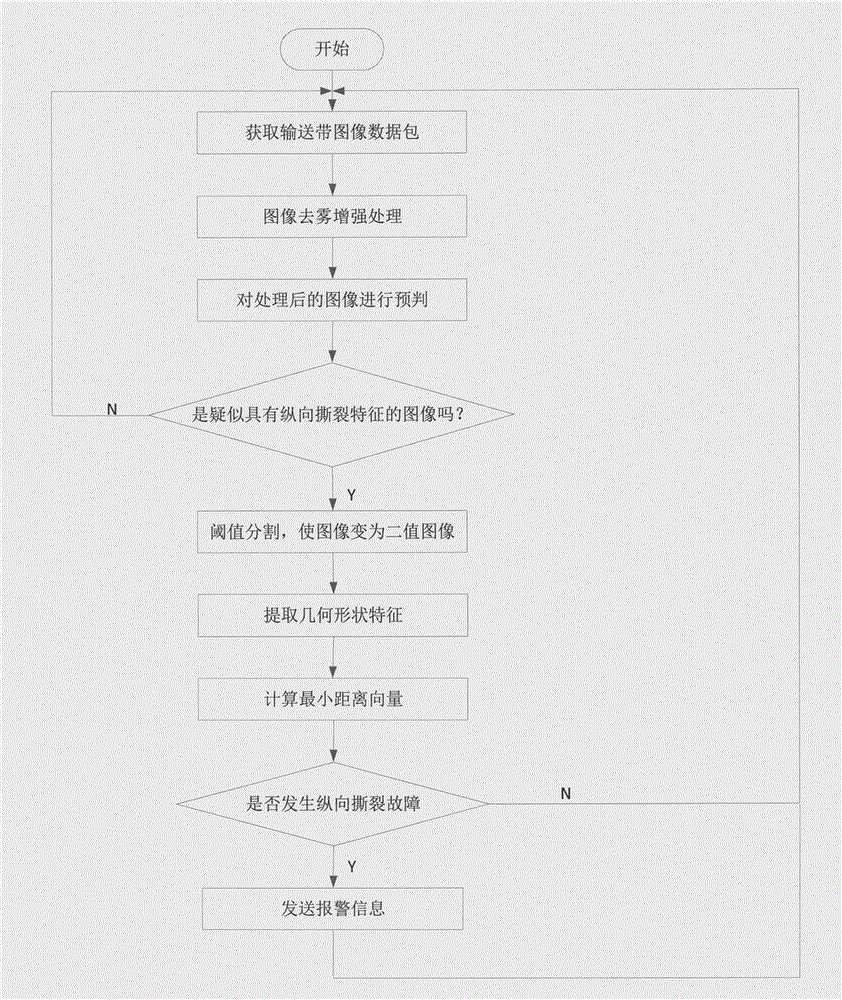

[0036] The overall flow of the method proposed by the present invention is as attached figure 1 As shown, in the specific implementation, it is generally divided into three parts to realize the conveyor belt image acquisition, the conveyor belt image processing, the conveyor belt fault detection and the alarm.

[0037] The realization of conveyor belt image acquisition:

[0038] The on-line detection system for longitudinal tearing failure of the conveyor belt running on the computer side needs to send collection parameters and collection commands to the linear CCD camera. The linear CCD camera collects the image data of the conveyor belt according to the received parameters and commands, and integrates it into a two-dimensional image and sends it to the conveyor belt longitudinal tear fault online detection system through Gigabit Ethernet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com