Method for utilizing gibberellins raffinate to prepare high-activity water flush fertilizer

A technology of gibberellin and raffinate, which is used in fertilization devices, applications, fertilizer mixtures, etc., to increase production, improve quality, and prevent pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

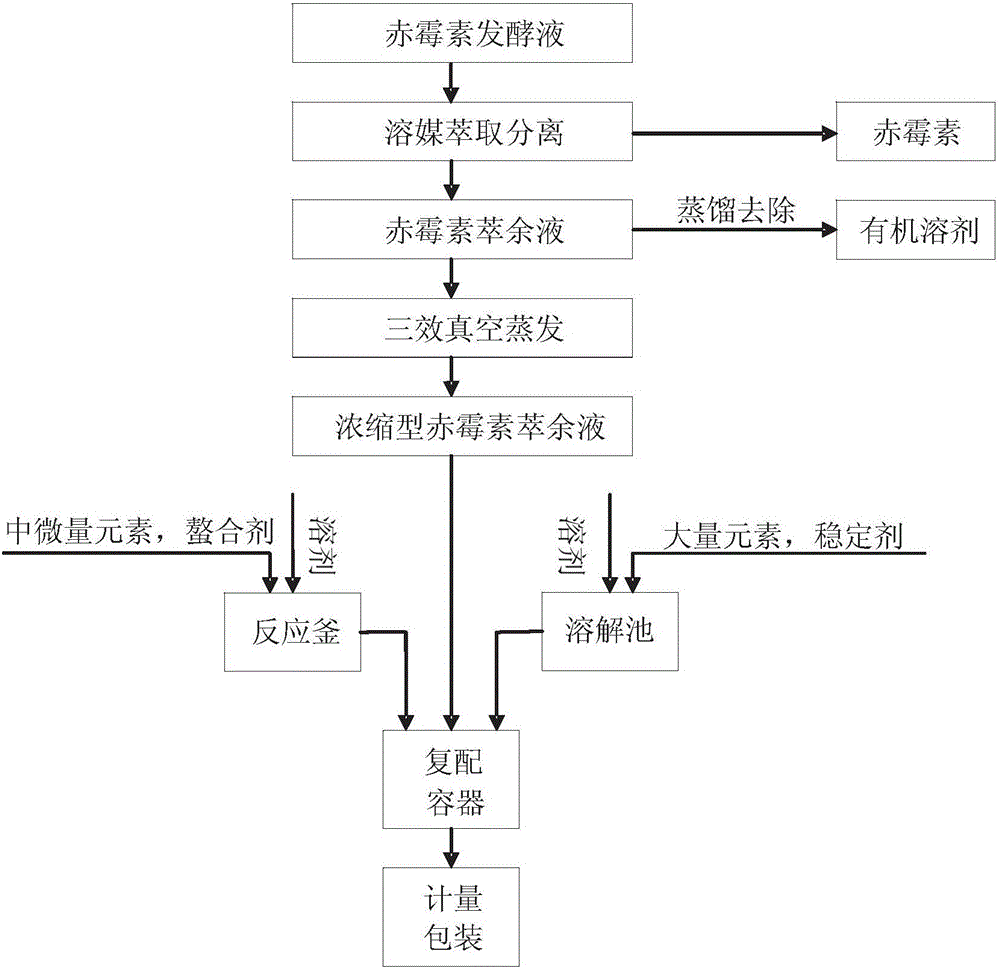

Image

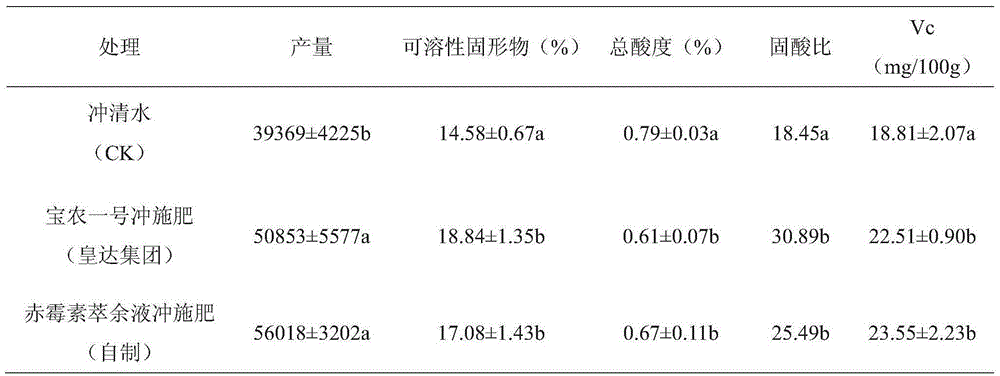

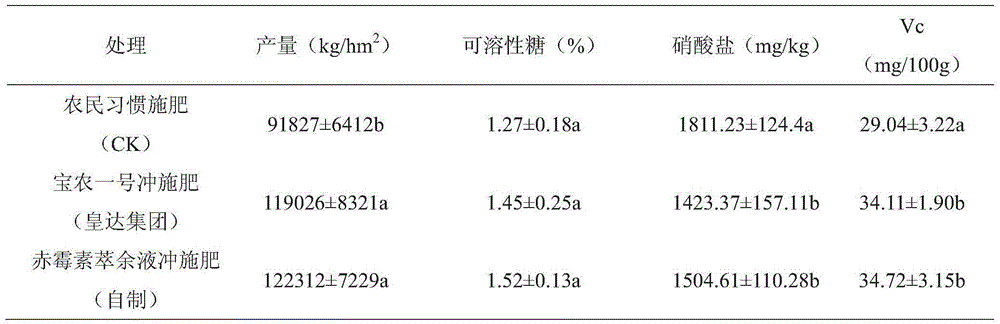

Examples

Embodiment 1

[0042] Step 1: Preparation of gibberellin raffinate concentrate

[0043] Extract 5 t of gibberellin fermentation liquid through solvent extraction to separate gibberellin active components to obtain 2.2 t of gibberellin extraction waste liquid; remove residual organic solvents from the above gibberellin extraction waste liquid by atmospheric distillation and evaporate in a three-effect vacuum Concentrate, the concentration ratio is more than 10 times, and the prepared gibberellin raffinate concentrated solution with a specific gravity of 1.3g / mL is 200kg; wherein, the amino acid content in the gibberellin raffinate concentrated solution is 10.1%.

[0044] Step 2: Adjustment of the pH value of the gibberellin raffinate

[0045] In the reaction kettle, use 1mol / L NaOH solution to adjust the gibberellin raffinate concentrate to pH 7 to obtain neutral gibberellin raffinate; wherein, the amount of NaOH is according to the formula pH=0.0234×NaOH+2.566 calculate.

[0046] Step 3: P...

Embodiment 2

[0054] Step 1: Preparation of gibberellin raffinate concentrate

[0055] Extract 5 t of gibberellin fermentation liquid through solvent extraction to separate gibberellin active components to obtain 2.2 t of gibberellin extraction waste liquid; remove residual organic solvents from the above gibberellin extraction waste liquid by atmospheric distillation and evaporate in a three-effect vacuum Concentrate, the concentration ratio is more than 10 times, and the prepared gibberellin raffinate concentrated solution with a specific gravity of 1.3g / mL is 200kg; wherein, the amino acid content in the gibberellin raffinate concentrated solution is 10.1%.

[0056] Step 2: Adjustment of the pH value of the gibberellin raffinate

[0057] In the reaction kettle, use 1mol / L NaOH solution to adjust the gibberellin raffinate concentrate to pH 7 to obtain neutral gibberellin raffinate; wherein, the amount of NaOH is according to the formula pH=0.0234×NaOH+2.566 calculate.

[0058] Step 3: P...

Embodiment 3

[0066] Step 1: Preparation of gibberellin raffinate concentrate

[0067] Extract 5 t of gibberellin fermentation liquid through solvent extraction to separate gibberellin active components to obtain 2.2 t of gibberellin extraction waste liquid; remove residual organic solvents from the above gibberellin extraction waste liquid by atmospheric distillation and evaporate in a three-effect vacuum Concentrate, the concentration ratio is more than 10 times, and the prepared gibberellin raffinate concentrated solution with a specific gravity of 1.3g / mL is 200kg; wherein, the amino acid content in the gibberellin raffinate concentrated solution is 10.1%.

[0068] Step 2: Adjustment of the pH value of the gibberellin raffinate

[0069] In the reaction kettle, use 1mol / L NaOH solution to adjust the gibberellin raffinate concentrate to pH 7 to obtain neutral gibberellin raffinate; wherein, the amount of NaOH is according to the formula pH=0.0234×NaOH+2.566 calculate.

[0070] Step 3: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com