Chlorella polysaccharide extraction method

An extraction method and chlorella technology, applied in the field of marine biology, can solve the problems of not being widely used, narrow extraction range and high operating cost, and achieve the effects of promoting rapid dissolution, avoiding nutrient loss and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

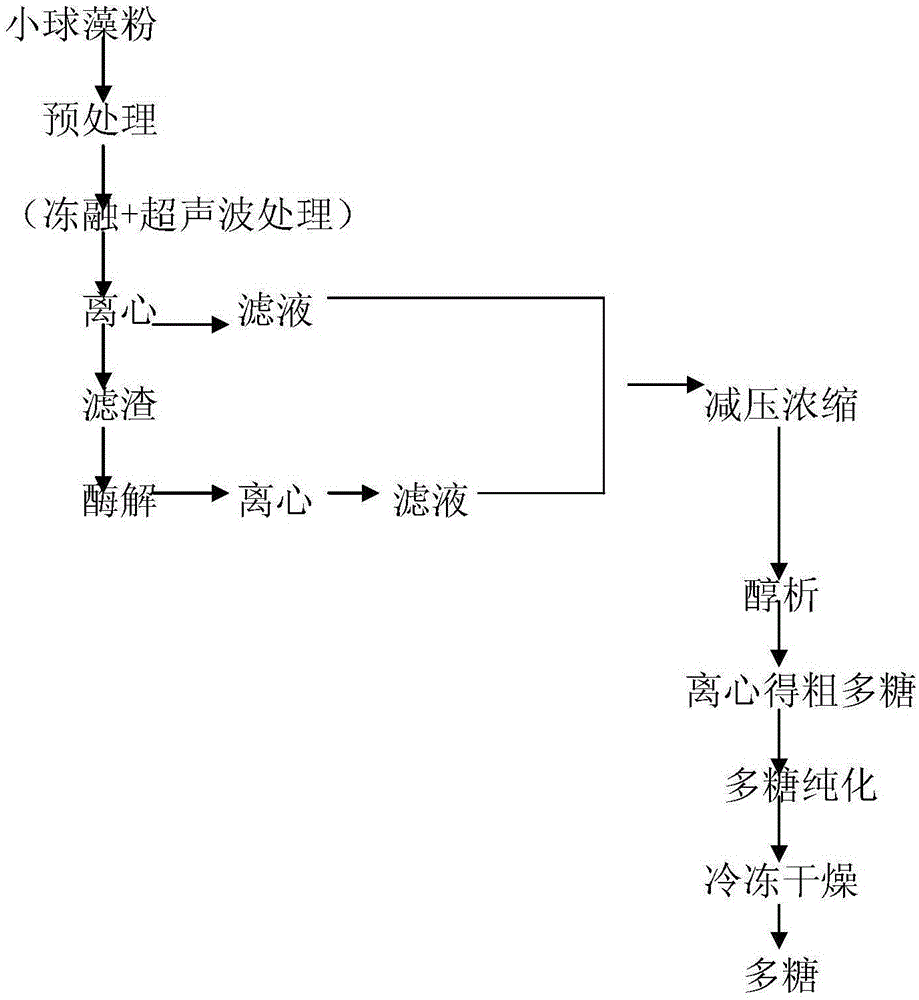

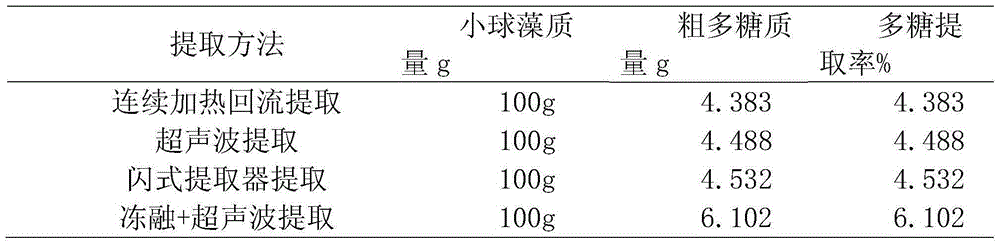

Method used

Image

Examples

Embodiment 1

[0015] 1. Pretreatment: Weigh 100g of chlorella powder and dissolve it in 500ml of distilled water to prepare a suspension with a concentration of 5%, put it in a 60°C water bath for 1 hour and keep stirring;

[0016] 2. Freeze-thaw and ultrasonic treatment: freeze the chlorella suspension at ~20°C and thaw at room temperature. Repeat the freeze-thaw process 4 times, freezing for 12 hours each time; then add 3 mL of phosphate buffer solution with a pH of 7.0 and a concentration of 0.01 mol / L, sonicate (400 W, time 4 min), and centrifuge in an ultracentrifuge at 2000 r / min for 5 min. Filtrate, the filtrate is standby;

[0017] 3. Enzymatic hydrolysis of the filter residue: add 200ml of distilled water to the filter residue in step 2 to prepare a 10% solution, add 1.0ml of trypsin, enzymolysis temperature 60°C, enzymolysis time 2h, centrifuge, speed control 4000r / min, time 10min, Filtrate, the filtrate is standby;

[0018] 4. Concentration under reduced pressure and alcohol an...

Embodiment 2

[0046] 1. Pretreatment: Weigh 200g of chlorella powder and dissolve it in 1000ml of distilled water to prepare a suspension with a concentration of 5%, put it in a water bath at 60°C for 1 hour and keep stirring;

[0047] 2. Freeze-thaw and ultrasonic treatment: freeze the chlorella suspension at ~20°C and thaw at room temperature. Repeat the freeze-thaw process 4 times, freezing for 12 hours each time; then add 5 mL of phosphate buffer solution with a pH of 7.0 and a concentration of 0.01 mol / L, sonicate (500 W, time 5 min), centrifuge at 2000 r / min for 5 min, and filter. The filtrate is ready for use;

[0048]3. Enzymatic hydrolysis of the filter residue: add 300ml of distilled water to the filter residue in step 2 to prepare a 15% solution, add 1.5ml of trypsin, enzymolysis temperature 55°C, enzymolysis time 2h, centrifuge, speed control 3500r / min, time 10min, Filtrate, the filtrate is standby;

[0049] 4. Concentration under reduced pressure and alcohol analysis: combine...

Embodiment 3

[0053] 1. Pretreatment: Weigh 50g of chlorella powder and dissolve it in 500ml of distilled water to prepare a suspension with a concentration of 10%, put it in a water bath at 60°C for 1 hour and keep stirring;

[0054] 2. Freeze-thaw and ultrasonic treatment: freeze the chlorella suspension at ~20°C and thaw at room temperature. Repeat the freezing and thawing process 4 times, freezing for 12 hours each time; then add 4.5 mL of phosphate buffer solution with a pH of 7.0 and a concentration of 0.01 mol / L, ultrasonicate (600 W, time 6 min), centrifuge at 2500 r / min for 5 min, filter , the filtrate is standby;

[0055] 3. Enzymatic hydrolysis of the filter residue: add 100ml of distilled water to the filter residue in step 2 to prepare a 20% solution, add 0.5ml of trypsin, enzymolysis temperature of 55°C, enzymolysis time of 2h, centrifuge at a speed of 4000r / min for 10min, Filtrate, the filtrate is standby;

[0056] 4. Concentration under reduced pressure and alcohol analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com