A kind of regeneration agent for hot regeneration of asphalt pavement

A technology for asphalt pavement and rejuvenating agent, which is applied in building components, building insulation materials, construction, etc., can solve the problems of high cost of rejuvenating agent, high mixing temperature, poor peeling resistance of recycled pavement, etc., and achieves the temperature stability of recycled asphalt. With the effect of improved viscoelastic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A regeneration agent for hot regeneration of asphalt pavement, its raw materials include the following components: petroleum heavy oil: 22 parts; waste oil: 19.5 parts; furfural extraction oil: 27 parts; styrene-butadiene rubber: 5.6 parts; dimethyl phthalate Esters: 3.3 parts; Manganese dioxide: 2.5 parts; Carbon black: 4.1 parts; Carolamine: 3.6 parts; Benzophenone: 4.2 parts; Aluminum chloride: 2.1 parts; share. Mix petroleum heavy oil and gutter oil, heat to 85°C; mix styrene-butadiene rubber, dimethyl phthalate, manganese dioxide, carbon black, carolamine, benzophenone, aluminum chloride, methyl silicone oil , Chloroform is mixed with petroleum heavy oil and gutter oil, and heat-preserved and stirred to form a mixture; the mixture is heated to 105° C., and furfural is added to extract the oil, and stirred to form the regenerant.

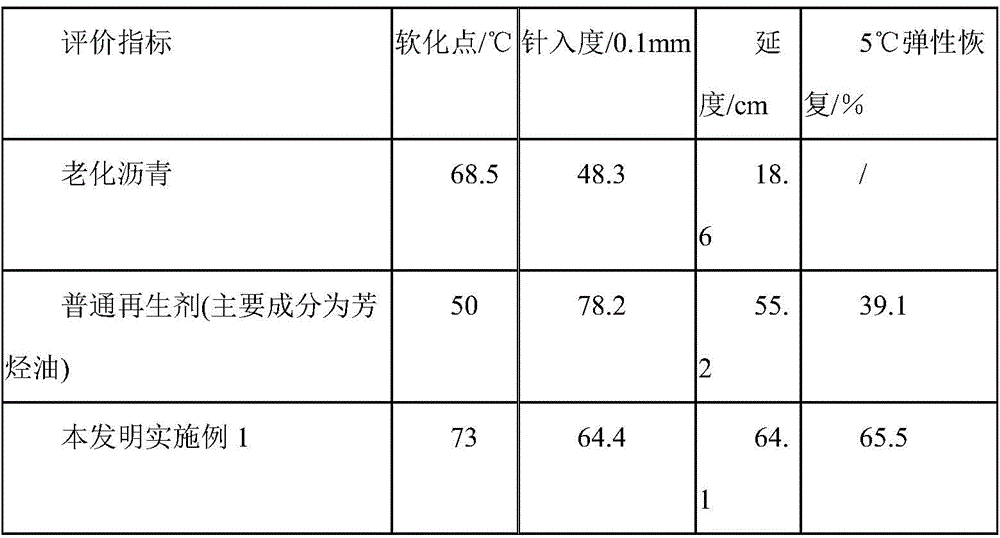

[0039] The regeneration effect of the regenerant prepared in this example is shown in Table 1. As shown in the table, the temperature s...

Embodiment 2

[0043] A regenerant for asphalt pavement heat regeneration, its raw material comprises the following components:

[0044] Petroleum heavy oil: 10.3 parts; waste oil: 16.2 parts; furfural extraction oil: 26 parts; styrene-butadiene rubber: 3.5 parts; dimethyl phthalate: 2.65 parts; manganese dioxide: 2.1 parts; carbon black: 3.4 parts ; Carolamide: 2.4 parts; Benzophenone: 2.8 parts; Aluminum chloride: 2.7 parts; Methyl silicone oil: 0.65 parts; Chloroform: 0.275 parts. Mix petroleum heavy oil and waste oil, heat to 88°C; mix styrene-butadiene rubber, dimethyl phthalate, manganese dioxide, carbon black, carolamine, benzophenone, aluminum chloride, methyl silicone oil , Chloroform is mixed with petroleum heavy oil and gutter oil, and heat-preserved and stirred to form a mixture; the mixture is heated to 98° C., and furfural is added to extract the oil, and stirred to form the regenerant.

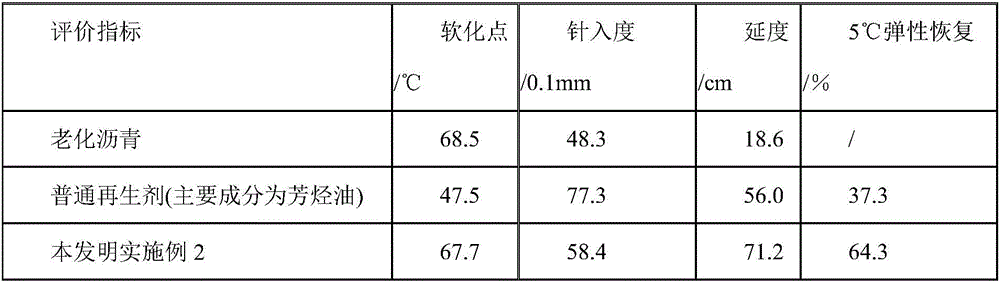

[0045] The regeneration effect of the regenerant prepared in this example is shown in Tab...

Embodiment 3

[0049] A regenerant for asphalt pavement heat regeneration, its raw material comprises the following components:

[0050] Petroleum heavy oil: 10.8 parts; waste oil: 17.2 parts; furfural extraction oil: 32 parts; styrene-butadiene rubber: 6 parts; dimethyl phthalate: 3.2 parts; manganese dioxide: 2.1 parts; carbon black: 3.4 parts ; Carolamide: 2.6 parts; Benzophenone: 2.3 parts; Aluminum chloride: 2.8 parts; Methyl silicone oil: 0.65 parts; Chloroform: 0.35 parts. Mix petroleum heavy oil and gutter oil and heat to 86°C; mix styrene-butadiene rubber, dimethyl phthalate, manganese dioxide, carbon black, carolamine, benzophenone, aluminum chloride, methyl silicone oil , chloroform is mixed with heavy petroleum oil and waste oil, and kept warm and stirred to form a mixture; the mixture is heated to 100° C., and furfural is added to extract the oil, and stirred to form the regenerant.

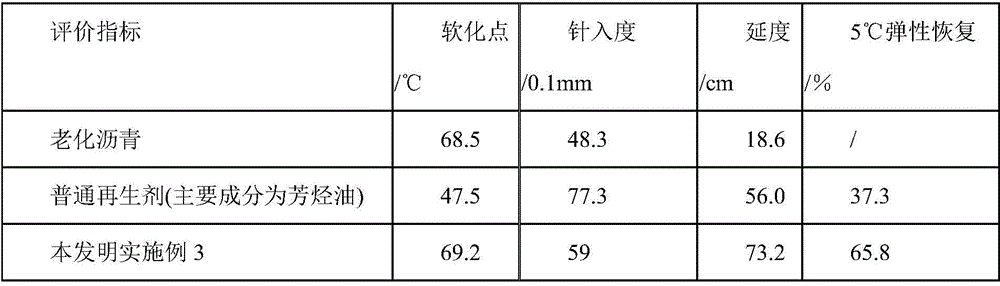

[0051] The regeneration effect of the regenerant prepared in this example is shown in Table 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com