Preparation methods of silver nanowires for conductive ink and silver nanowire electrode

A silver nanowire and conductive ink technology, applied in the field of printed electronics, can solve the problems of cumbersome preparation process of silver nanomaterials, inability to use large-scale production and application, harsh experimental conditions, etc., and achieve high yield, uniform size, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

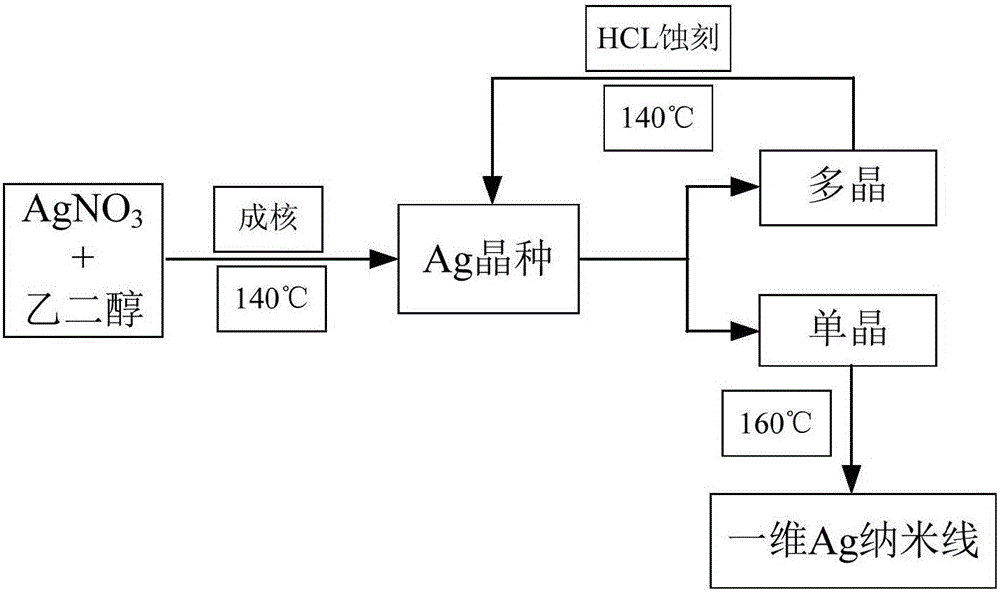

[0018] The embodiment of the present invention provides a method for preparing silver nanowires for conductive ink, comprising the following steps:

[0019] S01. Dissolving the silver ion salt and the protective agent in a reducing solvent to form a mixed solution, adding an etchant to the mixed solution to prepare a precursor solution;

[0020] S02. The precursor solution is heated and stirred twice to prepare silver nanowires for conductive inks, wherein, the method for twice heated and stirred is:

[0021] The first heating and stirring treatment: heating and stirring at 135-145°C for 110-130min;

[0022] The second heating and stirring treatment: heating and stirring at 155-165° C. for 25-35 minutes.

[0023] Specifically, in the above step S01, the mixed solution simultaneously contains silver ion salt, a protective agent, and a reducing solvent.

[0024] Wherein, the silver ion salt is an organic or inorganic silver ion salt that can exist as a cation in the reducing s...

Embodiment 1

[0044] A method for preparing a flexible electrode, comprising the following steps:

[0045] Q11. preparing conductive ink silver nanowires, comprising the following steps:

[0046] S11. Add 100mgAgNO 3 Dissolve 100mg of PVP in 30ml of EG, and add 2ulHCl (1M) to it after dissolving evenly to prepare a precursor solution;

[0047] S12. Pour the precursor solution into a flask and heat and stir twice in turn,

[0048] Wherein, the first heating and stirring treatment is placed in a heat-collecting magnetic stirrer at 140° C. and heated and stirred for 2 hours. The reaction equation of the first heating and stirring treatment is as follows:

[0049] 2HOCH 2 CH 2 OH→2CH 3 CHO+2H 2 O(S121)

[0050] 2Ag + +2CH 3 CHO→CH 3 CHO-OHCCH 3 +2Ag+2H + (S122)

[0051] 4HNO 3 +3Ag→3AgNO 3 +NO+2H 2 O(S123),

[0052] Wherein, the reaction formula S123 embodies the reaction process in which the polycrystalline nucleus is etched.

[0053] In the second heating and stirring treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com