Preformed automobile-damping expandable rubber belt with good oil surface construction and preparation method therefor

A technology for automobile shock absorption and preforming, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., it can solve the problems of high VOC content and poor environmental performance, so as to improve production efficiency and save energy. , Good effect of low temperature construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

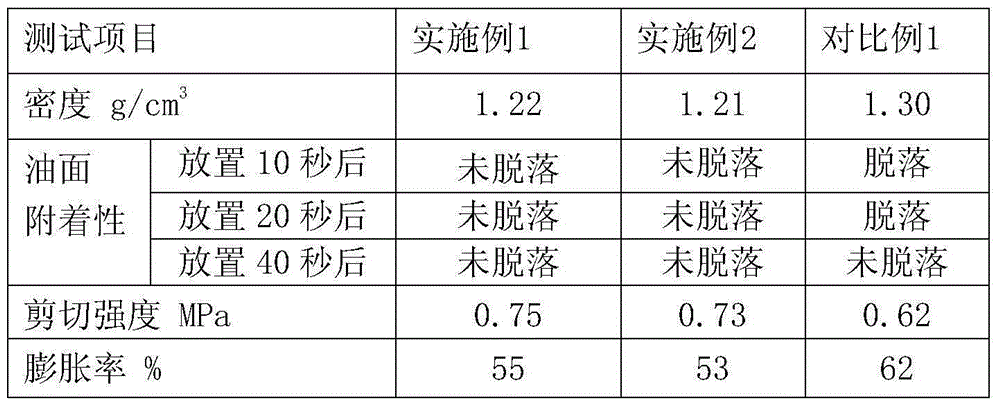

Examples

preparation example Construction

[0025] The embodiment of the present invention also provides a preparation method of a preformed automobile shock-absorbing expansion tape with good oil surface construction, which is used to produce the expansion tape of the present invention. The raw materials for preparing the expansion tape are obtained according to the formula of the present invention, including the following steps:

[0026] 1) After mixing solid epoxy resin, solid non-polar rubber and liquid rubber evenly, knead in a pressurized kneader for 7 to 11 minutes;

[0027] 2) After mixing the remaining raw materials, gradually add the pressurized kneader, add one-third of the total weight of the mixed raw materials each time, and knead in the pressurized kneader for 5 to 8 minutes; After all the remaining raw materials are added and mixed uniformly, the expansion tape matrix composition is obtained;

[0028] 3) Extrude the expanded tape base composition prepared above through a rubber extruder according to the ...

Embodiment 1

[0033] This embodiment provides a preformed automobile shock-absorbing expansion tape with good oil surface construction. The preparation method of the expansion tape is as follows:

[0034] In parts by weight, add butadiene rubber BR900025 parts by weight, liquid polybutadiene (1,2-LPB) 18 parts by weight, and solid epoxy resin E205 parts by weight into a pressurized kneader, kneading for 10 minutes;

[0035] 16 parts by weight of naphthenic oil, 0.4 parts by weight of dicyandiamide, 0.8 parts by weight of DTDM, 0.8 parts by weight of CZ, 9 parts by weight of foaming agent AC, 6 parts by weight of zinc oxide, 9 parts by weight of spray carbon black and light After preparing 25 parts by weight of calcium carbonate, gradually add to the pressurized kneader, add 1 / 3 of the total weight each time, and knead for 8 minutes after each addition; add all raw materials and mix them evenly to obtain the expansion tape matrix composition Adopt rubber extruder to extrude the expansion tap...

Embodiment 2

[0037] This embodiment provides a preformed automobile shock-absorbing expansion tape with good oil surface construction. The preparation method of the expansion tape is the same as in Example 1, except that the raw materials used are different, as follows:

[0038] SBR150225 parts by weight of styrene-butadiene rubber, 18 parts by weight of liquid polybutadiene (1,2-LPB), 5 parts by weight of solid epoxy resin E205 parts by weight, 16 parts by weight of naphthenic oil, 0.4 parts by weight of dicyandiamide, 0.8 parts by weight of DTDM Part, CZ0.8 weight part, whipping agent AC9 weight part, zinc oxide 6 weight parts, spray carbon black 9 weight parts and light calcium carbonate 25 weight parts, its preparation method is with embodiment 1. Obtain the example 2 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com