Sandwich layer artificial stone and making method thereof

An artificial stone and sandwich technology, applied in the field of building materials, can solve the problems of long production time, high construction cost, complicated decoration process, etc., and achieve the effect of increased strength and toughness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

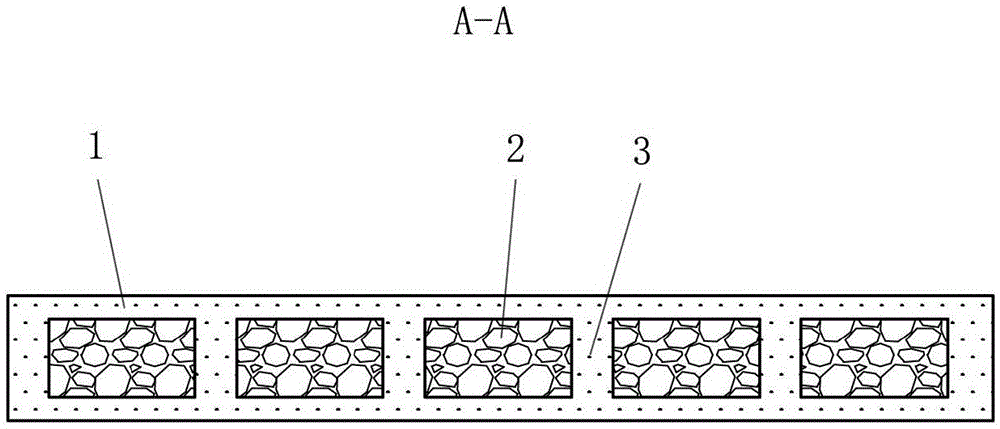

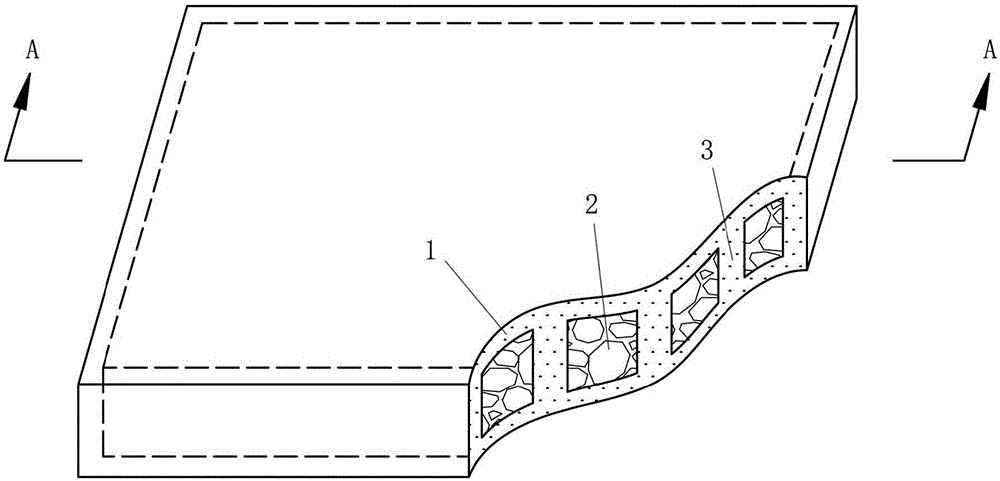

[0023] refer to figure 1 and figure 2 , the present embodiment designs and manufactures the sandwich interlayer artificial marble of 600mmх600mm. Use a vacuum-capable sealed mold, mix natural marble stone powder and paste resin with a weight percentage of 10:1 to make a marble stone powder slurry; use a weight percentage of 1:2 full-water polyurethane and ceramsite to evenly mix to make a 25mm thickness The whole water polyurethane ceramsite board 2, in the whole water polyurethane ceramsite board 2, the average is about 10cm 2 Make 4 through holes with a diameter of 8mm evenly in the range.

[0024] First pour a layer of 3mm thick marble stone powder slurry on the bottom of the mold, place a 25mm thick full-water polyurethane ceramsite board 2 on the marble stone powder slurry, and pour 3mm and 20mm thick ceramsite boards on and around the full-water polyurethane ceramsite board. Marble stone powder slurry, so that the upper and lower layers and the surrounding and the th...

Embodiment 2

[0026] refer to figure 1 and figure 2 , present embodiment makes the sandwich interlayer artificial jade slab of 500mmх500mm, and its artificial stone 1 upper and lower layers and surrounding thickness are set to 2mm and 15mm. A vacuum-sealable mold is used, and the jade powder slurry is made by mixing natural building jade stone powder and paste resin with a weight percentage of 10:1; a 20mm thick is made of a 1:2 weight percentage of full-water polyurethane and ceramsite. 2 of all-water polyurethane ceramsite boards, each about 10cm 2 Make 4 through holes with a diameter of 6mm evenly in the range.

[0027] First pour a layer of 2mm thick stone powder slurry on the bottom of the mold, place a 20mm thick full-water polyurethane ceramsite board 2 on it, and pour jade powder slurry on it, so that the upper and lower layers and the surrounding and middle through holes All are filled with jade powder slurry, and are connected with the upper and lower artificial stones to beco...

Embodiment 3

[0029]To make 600mmх300mm sandwich interlayer artificial stone, choose various natural stone mixed stone powder, use the ratio of about 10:1 by weight to mix natural stone mixed stone powder and cured resin to make stone mixed stone powder slurry; use 1:1 ratio to make 15mm Thick full water polyurethane ceramsite board 2, on the full water polyurethane ceramsite board 2, every about 10cm 2 Make 3 through holes with a diameter of 8mm evenly in the range.

[0030] Use a vacuum sealed mold to cast sandwich interlayer mixed stone powder artificial stone. After pouring a layer of 3mm thick mixed stone powder slurry on the bottom layer, place a 15mm thick full-water polyurethane ceramsite board 2, and then pour 3mm and 20mm thick on and around it. When the mixed stone powder slurry is completely filled with the upper layer, surroundings and all through holes, the mold is vibrated, pressed and vacuumed to make the entire interlayer artificial stone evenly, densely and evenly integrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com