Safe and reliable two-section type covering and uncovering device for ladle

A technology of ladle and capping, which is applied to transmissions, metal processing equipment, belts/chains/gears, etc., can solve problems such as small space, prolong service life, reduce steelmaking costs, and avoid smoke and dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

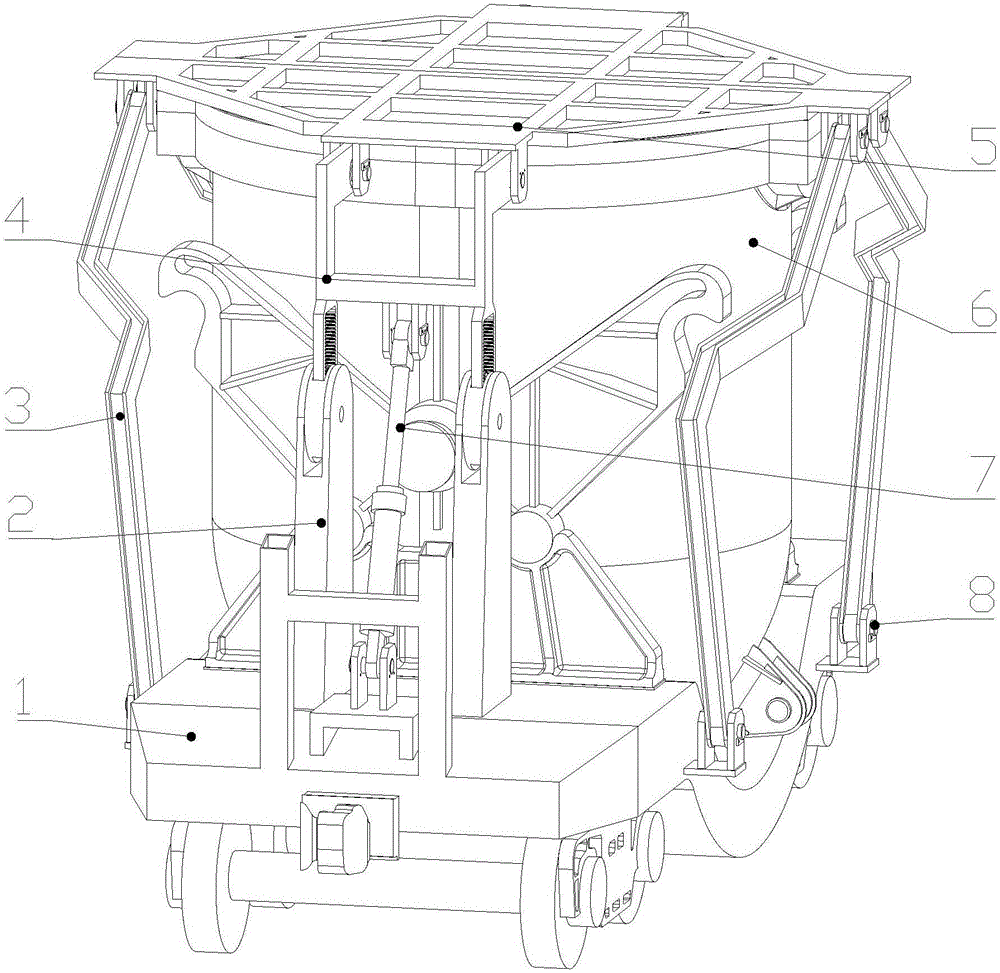

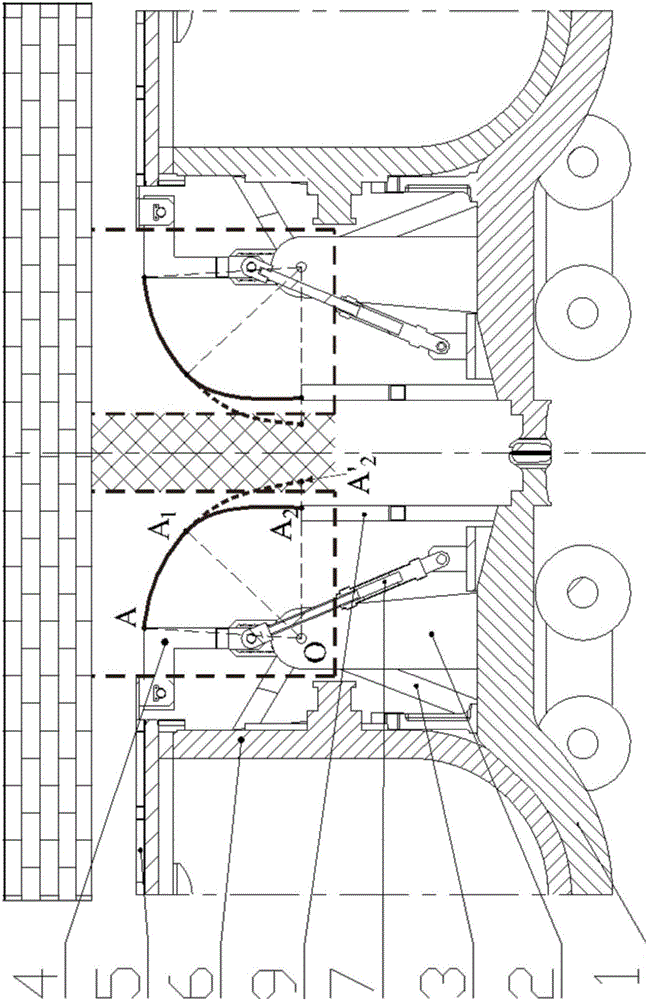

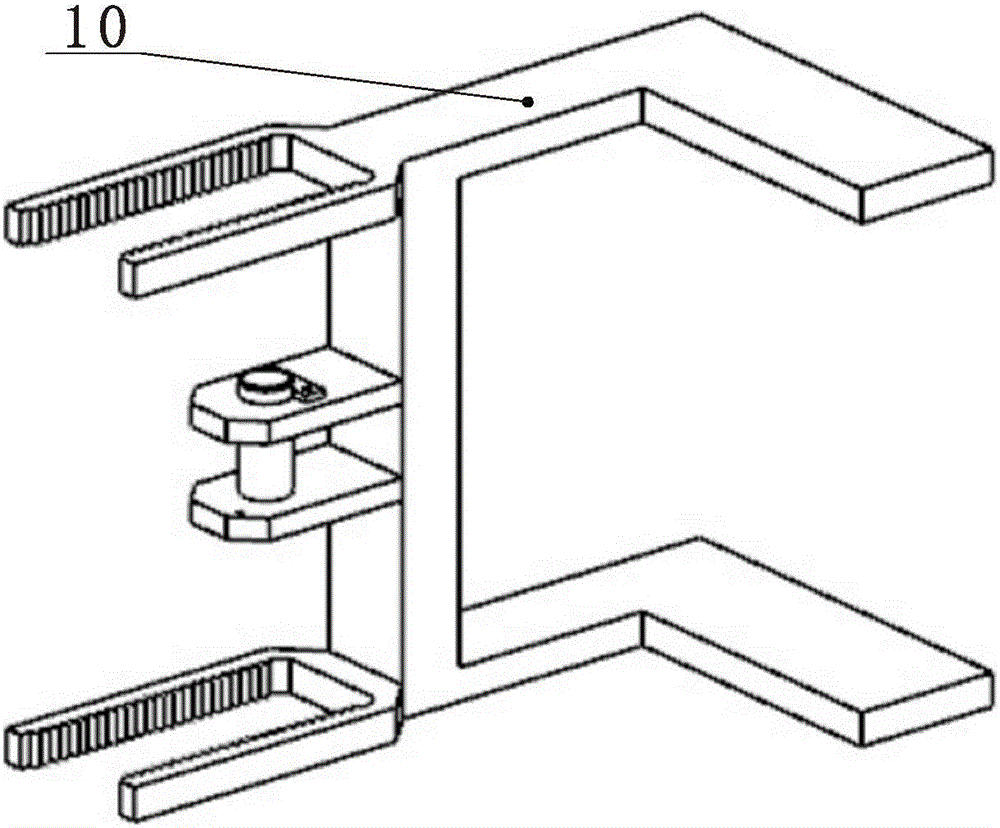

[0024] The safe and reliable double-lobe type molten iron ladle cover removing device of the present invention comprises a molten iron ladle cover 5 , an electro-hydraulic push rod 7 and a base 2 . The two ends of the ladle cover 5 are rotatably connected with the guide rocker 3 and the telescopic rocker 4 through the high temperature resistant pin 8 respectively. The high temperature resistant pin shaft 8 is provided with a groove, and the high temperature resistant pin 25 is fixed in the groove with a connecting screw 26 . The other end of the guide rocker 3 is rotationally connected with the molten iron transport vehicle 1 through a high temperature resistant pin 8 . The telescopic rocker 4 includes a rocker arm 10 and a gear transmission box, the gear transmission box includes a box body, and the box body is composed of a first box body 22 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com