Particle granularity measuring apparatus based on divergent ultrasonic attenuation and method thereof

A measuring device, ultrasonic technology, applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of actual fluctuation difference, limited sensor size, impossible to generate plane waves, etc., to achieve the effect of high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

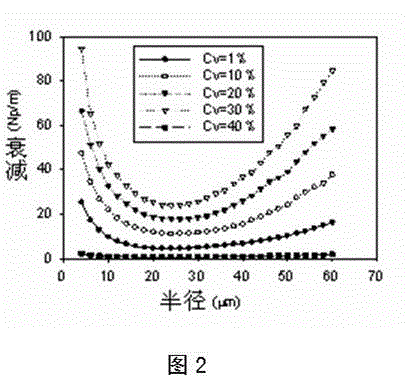

[0029] The device for measuring the particle size based on the method of divergent ultrasonic waves provided by the embodiment of the present invention is characterized in that the particle size can be accurately measured by using the sound change of the divergent ultrasonic waves.

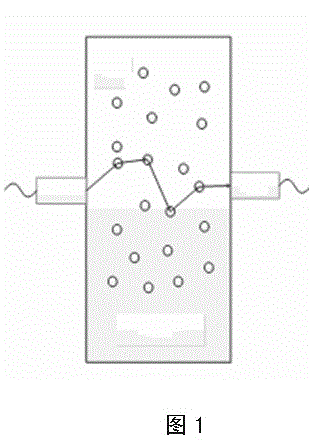

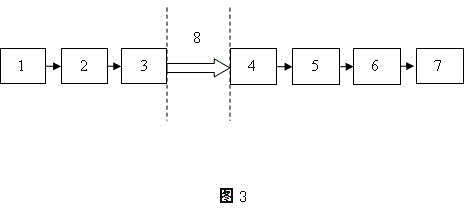

[0030] The basic principle of divergent ultrasonic measurement is that it uses the incident divergent ultrasonic wave to be scattered and absorbed by the granular medium, and its transmitted sound intensity will be attenuated. Through modeling based on the Monte-Carlo method, the attenuation value can be predicted theoretically and the attenuation can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com