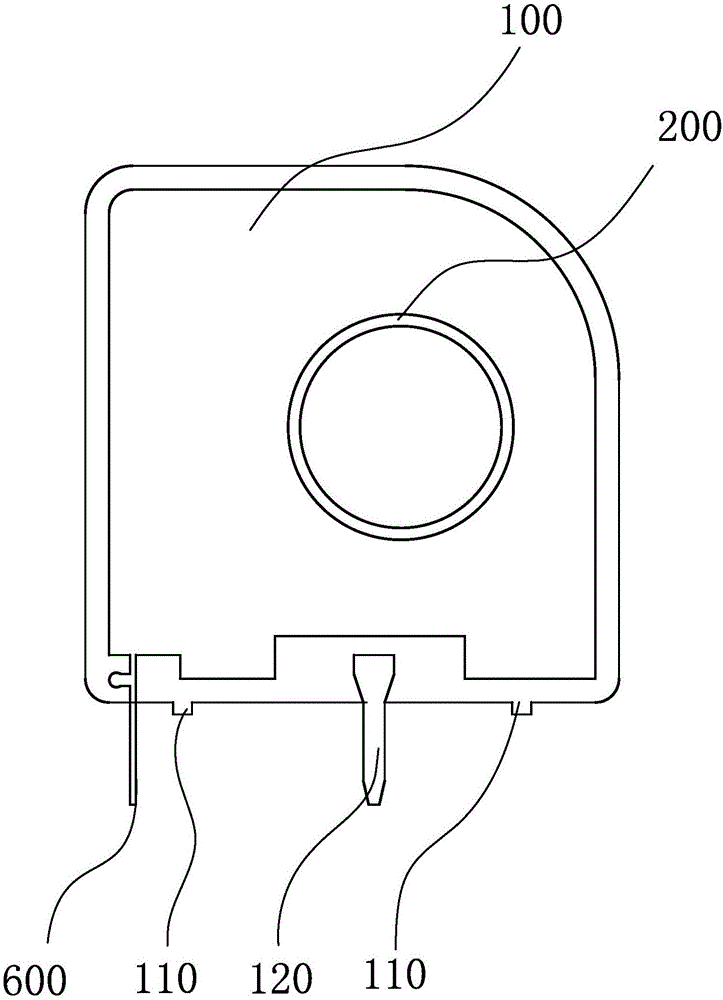

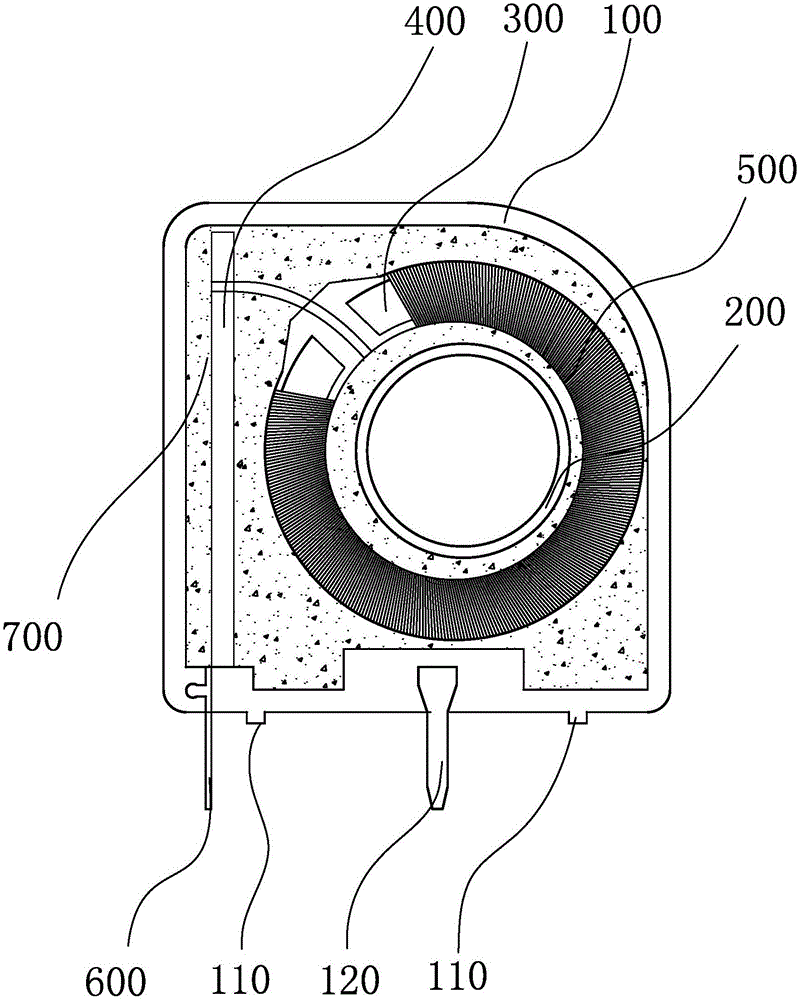

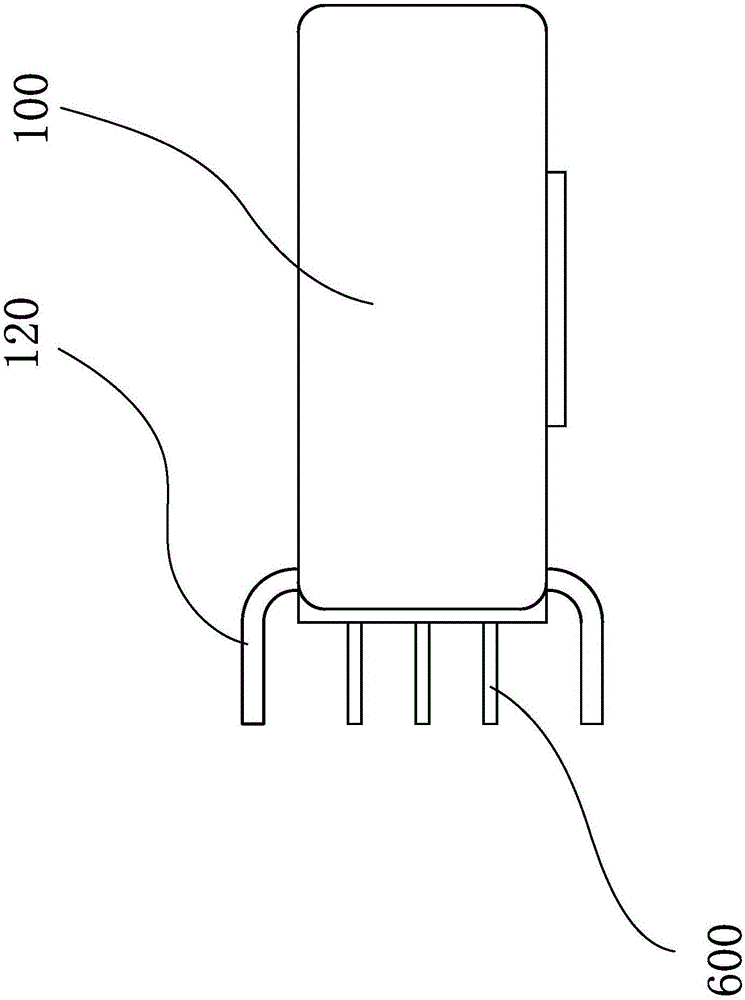

Closed-loop Hall current sensor

A current sensor, closed-loop Hall technology, applied in the field of sensors, can solve the problems of low precision, inconvenient installation, poor anti-interference ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The raw materials were weighed according to the composition and parts by weight of the ring mounting part in Example 1 in Table 1. Among them, the fibrous material is carbon fiber, the metal powder is iron powder with a particle size of 150nm, the antistatic agent is fatty acid polyol ester, the toughening agent is nano-calcium carbonate coated with POE-g-MAH, and the flame retardant is phosphorus-g-MAH. The nitrogen flame retardant, the formaldehyde absorber melamine, the formic acid absorber is sodium oxide, and the antioxidant is a commercially available antioxidant.

[0068] During preparation, the annular mounting part is made by injection molding, extrusion, extrusion or blow molding.

Embodiment 2

[0070] The raw materials were weighed according to the composition and parts by weight of the annular mounting part of Example 2 in Table 1. Among them, the fibrous material is carbon fiber, the metal powder is iron powder with a particle size of 150nm, the antistatic agent is fatty acid polyol ester, the toughening agent is nano-calcium carbonate coated with POE-g-MAH, and the flame retardant is phosphorus-g-MAH. The nitrogen flame retardant, the formaldehyde absorber melamine, the formic acid absorber is sodium oxide, and the antioxidant is a commercially available antioxidant.

[0071] During preparation, the annular mounting part is made by injection molding, extrusion, extrusion or blow molding.

Embodiment 3

[0073] The raw materials were weighed according to the composition and parts by weight of the ring mounting part of Example 3 in Table 1. Among them, the fibrous material is carbon fiber, the metal powder is iron powder with a particle size of 150nm, the antistatic agent is fatty acid polyol ester, the toughening agent is nano-calcium carbonate coated with POE-g-MAH, and the flame retardant is phosphorus-g-MAH. The nitrogen flame retardant, the formaldehyde absorber melamine, the formic acid absorber is sodium oxide, and the antioxidant is a commercially available antioxidant.

[0074] During preparation, the annular mounting part is made by injection molding, extrusion, extrusion or blow molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com