Submerged arc horizontal position welding testing device

A test device and horizontal welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of less use of hydraulic power steel pipes, different diameters and sizes, and complex steel plate materials, so as to improve welding quality and improve Flux recovery rate, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

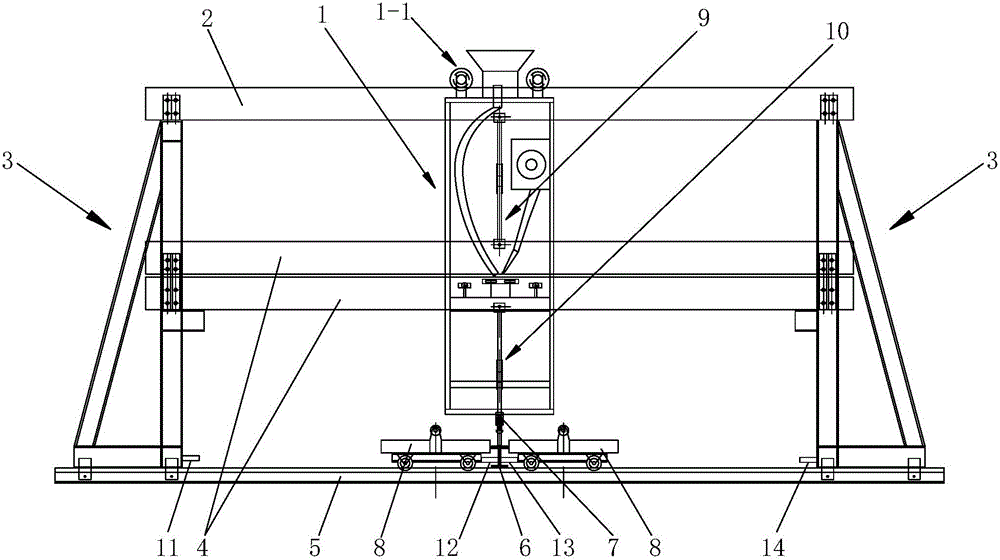

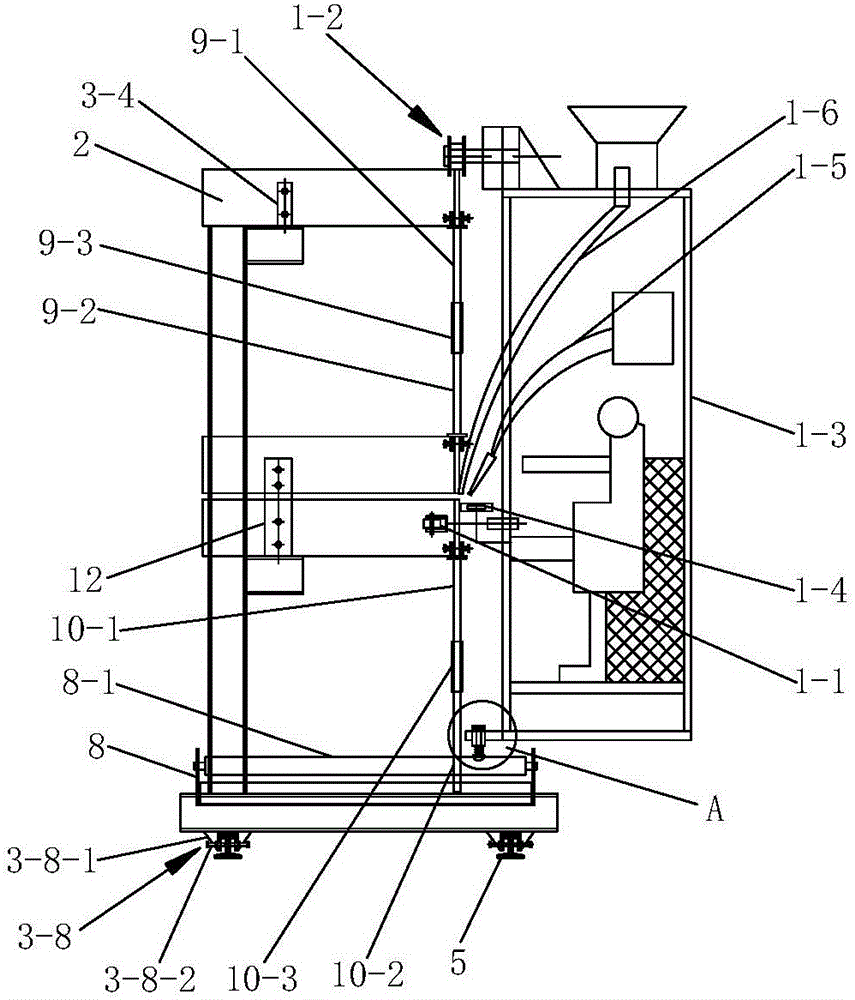

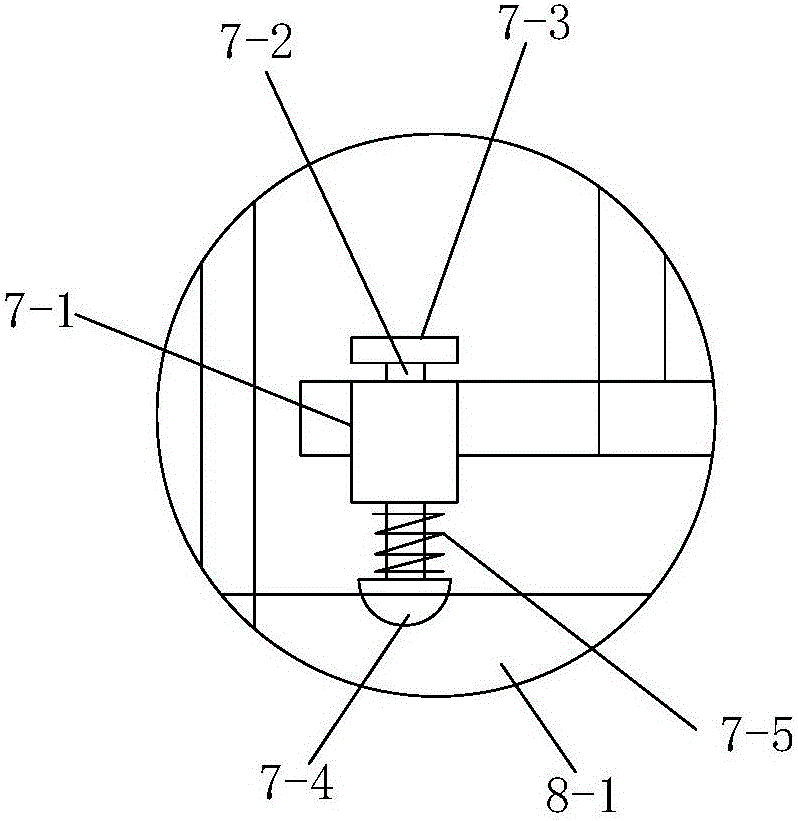

[0065] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown a submerged arc horizontal welding test device includes a submerged arc transverse seam welding machine 1, a support track 5 and two support column mechanisms 3 arranged on the support track 5, and the two support column mechanisms 3 There are two test plates matched with the guide wheel 1-1 of the submerged arc transverse seam welding machine 1, both of the test plates are curved test plates 4 or flat test plates 16, and the two support A simulated track for guiding the moving wheels 1-2 of the submerged arc transverse seam welding machine 1 to walk is arranged between the column mechanism 3. The simulated track is a curved surface simulated track 2 or a plane simulated track 15, and the simulated track is located on the test bench. Above the board, the middle parts of the two supporting column mechanisms 3 are provided with a curved panel locking mechanism 3-6 and a flat panel locking mechanism 3-5, an...

Embodiment 2

[0086] Such as Figure 12 , Figure 13 and Figure 14 As shown, the difference between this embodiment and Embodiment 1 lies in that: the two test boards are plane test boards 16 , and the simulated track is a plane simulated track 15 .

[0087] In this embodiment, by installing the plane test plate 16 and the plane simulation track 15, the welding process evaluation can be effectively performed.

[0088] Such as Figure 12 As shown, the upper end of the first upper screw rod 9-1 of the upper auxiliary support member 9 is fixedly connected to the plane simulation track 15, and the lower end of the second upper screw rod 9-2 is fixedly connected to the flat test plate 16. ; The upper end of the first lower screw rod 10 - 1 of the lower auxiliary support member 10 is fixedly connected with the plane test plate 16 , and the lower end of the second lower screw rod 10 - 2 is fixedly connected with the support rod 6 .

[0089] In this embodiment, when the upper auxiliary support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com