Variable-camber section inner cylindrical surface airflow assisting abrasive flow polishing device

A processing device and variable curvature technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problem that the effect is not obvious, and the polishing of the inner wall surface of the tubular workpiece with variable curvature section is not suitable and uneven and other problems, to achieve the effect of low surface roughness, high surface accuracy and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with the accompanying drawings, the present invention will be described in detail below.

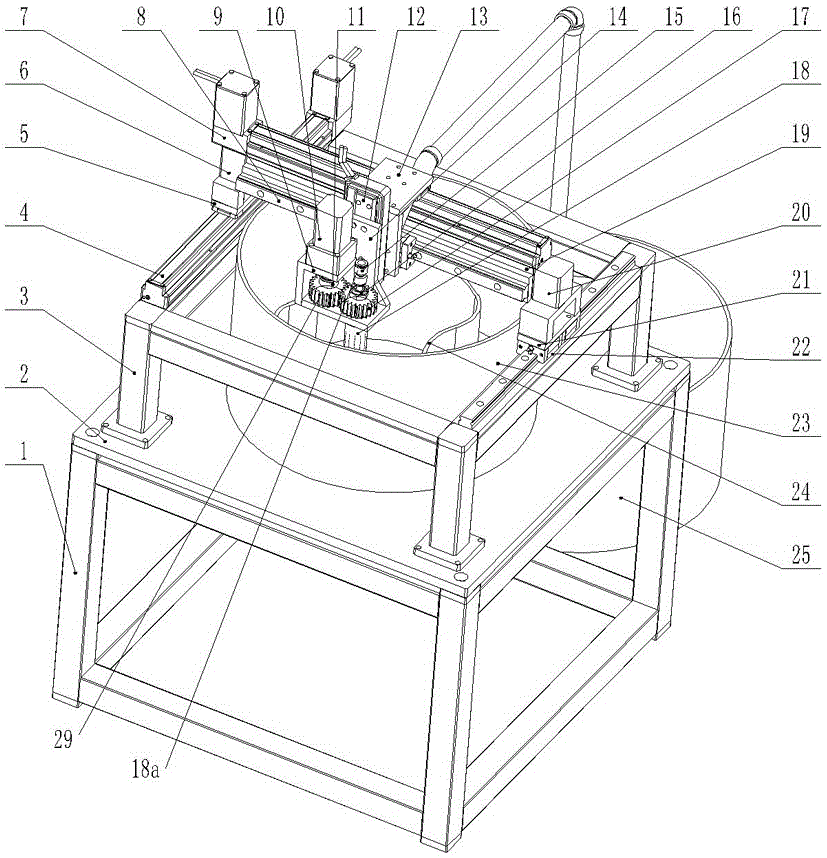

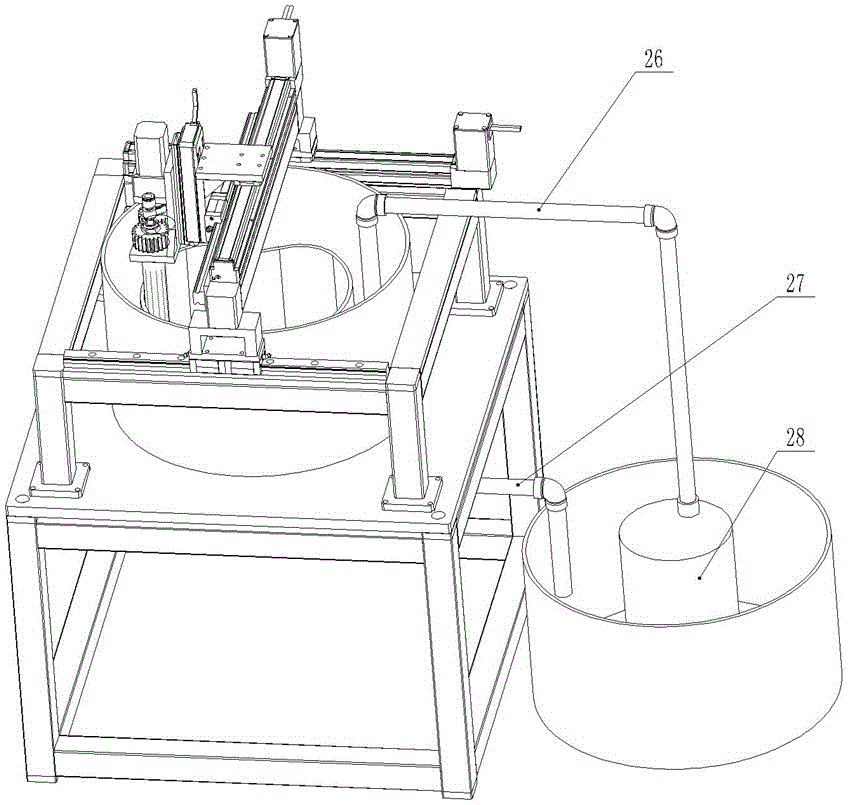

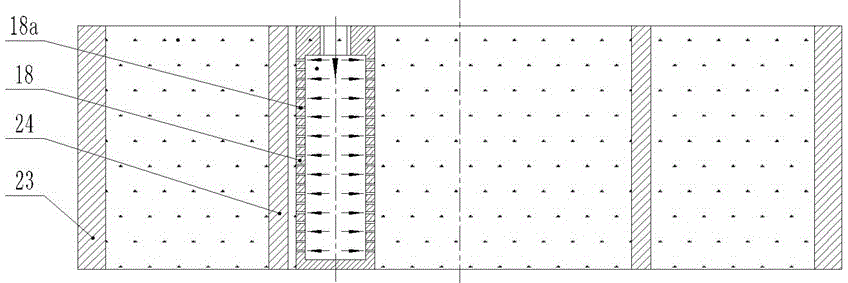

[0027] Refer to attached Figure 1-4, a cylindrical airflow assisted abrasive flow polishing processing device with a variable curvature cross-section of the present invention is used for polishing a tubular workpiece with a variable curvature cross-section, and it includes a mounting frame, which is a double-layer structure, including a frame 1 and a rack panel 2, the rack panel 2 is provided with a three-axis servo drive system installation frame 3, and the middle part of the surface of the rack panel 2 is equipped with a processing liquid storage tank 23; the three-axis servo drive system installation frame 3 is used for The precision three-axis servo drive system is installed, the abrasive particle flow circulation system is installed on the installation frame, the servo motor drive system is installed on the three-axis servo drive system mounting frame 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com