Automatic perforating machine with camera tracking and humidity controlling functions and perforating method

A humidity control and camera technology, applied in metal processing, sampling devices, etc., can solve problems such as damage, waste of labor, cross-contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention is described in detail below in conjunction with accompanying drawing:

[0087] The invention provides an automatic punching machine with camera tracking and humidity control, which can effectively solve the phenomenon of blood spot deviation caused by static electricity and improve the efficiency of punching and sampling due to the integrated humidity control. Due to the integrated camera tracking, the punching effect can be further detected to ensure the correct reliability of punching sampling; in addition, the present invention can fully automatically control the entire punching and sampling process, and while ensuring a simple structure, it also has automatic It has the advantages of high control precision in the punching sampling process.

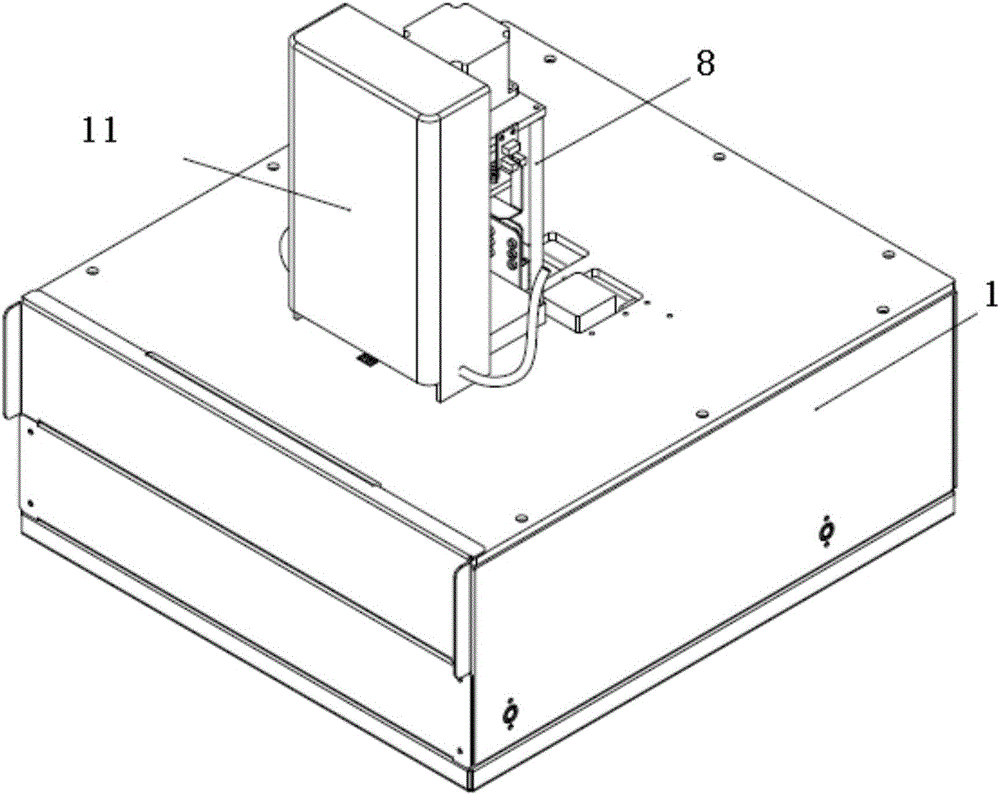

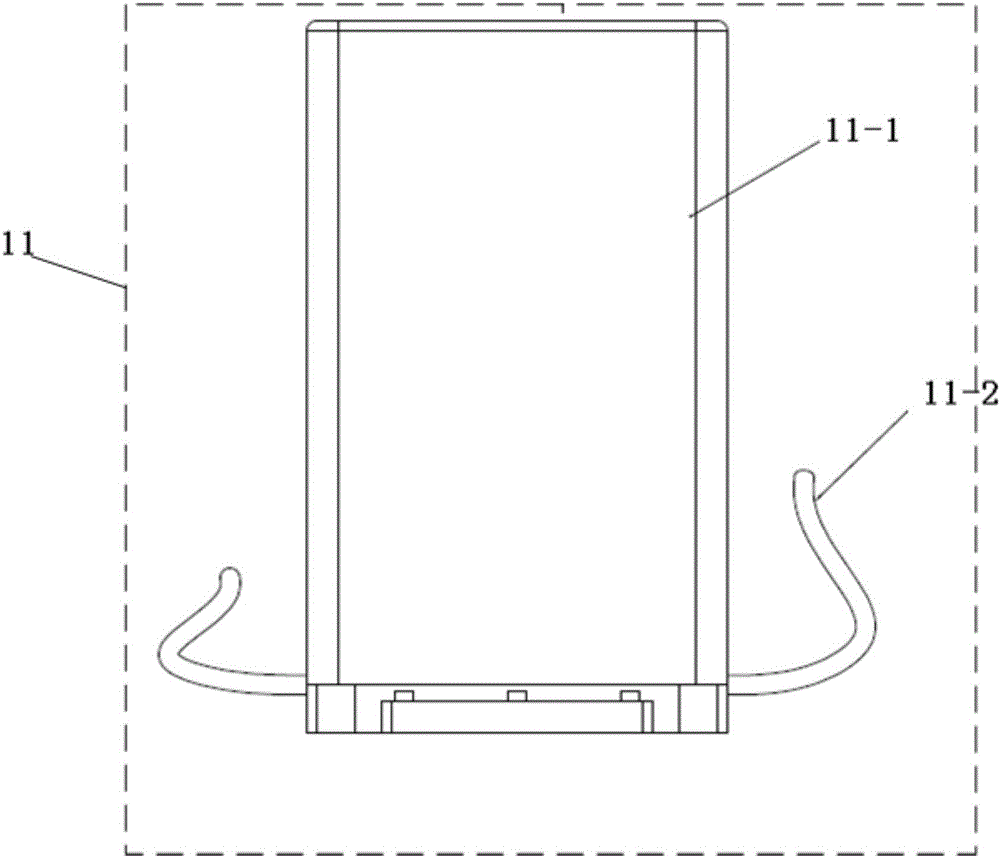

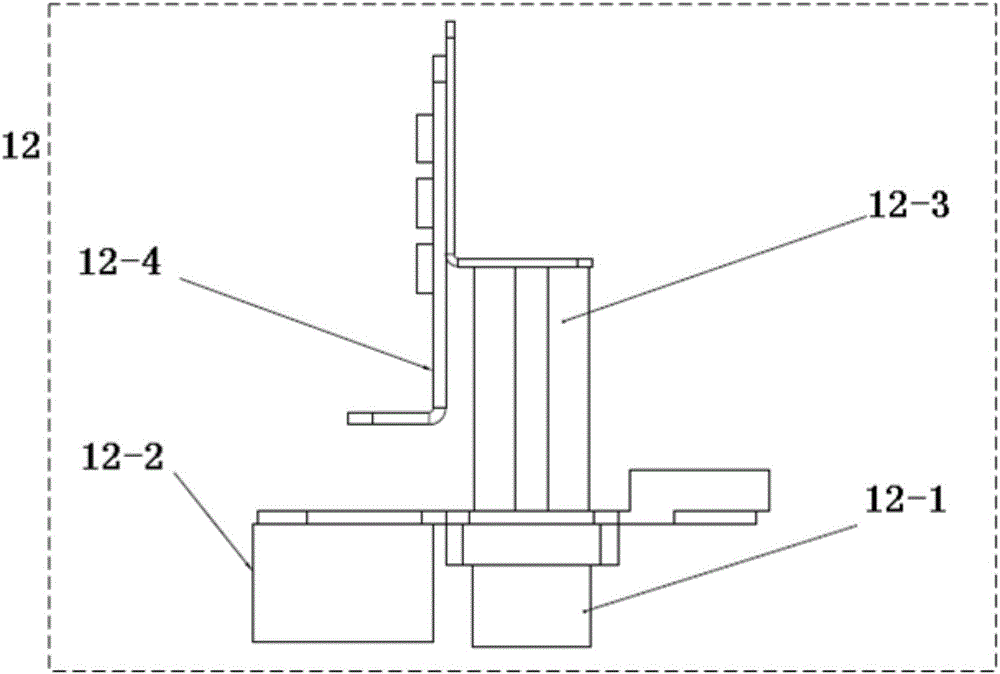

[0088] Specifically, the automatic punching machine with camera tracking and humidity control provided by the present invention, such as figure 1 As shown, it is a schematic diagram of the overall structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com