Modified polyester hot melt adhesive and preparation method for adhesive film thereof

A polyester hot-melt adhesive and modified polyester technology, applied in the direction of polyurea/polyurethane adhesives, film/sheet adhesives, adhesives, etc., can solve the problem of poor, brittle metal-epoxy resin Adhesive effect, poor toughness and other problems, to achieve the effect of good low temperature toughness, good elasticity and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

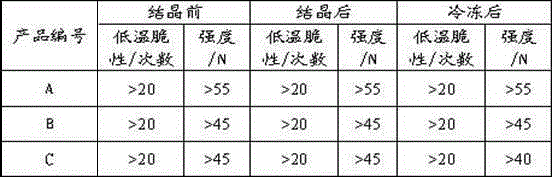

Examples

Embodiment 1

[0024] A low-temperature-resistant modified polyester hot-melt adhesive film is characterized in that its composition and mass content include: 35 parts of polyester hot-melt adhesive, 65 parts of thermoplastic polyurethane elastomer, and 0.5 part of antioxidant; its preparation method includes Follow the steps below:

[0025] (1) Selection of raw materials;

[0026] (2) Polyester hot melt adhesive, thermoplastic polyurethane elastomer and antioxidant are mixed evenly in the high mixer;

[0027] (3) Put the uniformly mixed raw materials into the twin-screw extrusion granulation unit, melt blending and extruding;

[0028] Extrusion temperature: the temperature from the barrel to the head is 170°C, 175°C, 175°C, 175°C, 175°C, 180°C;

[0029] Host speed: 100rpm;

[0030] Feeding speed: 20rpm;

[0031] (4) The extruded mixture is water-cooled and granulated, and the extruded pellets are dried in a vacuum oven for 12 hours at a temperature of 80°C, and then the dried pellets ar...

Embodiment 2

[0033] A low-temperature-resistant modified polyester hot-melt adhesive is characterized in that its composition and mass content include: 45 parts of polyester hot-melt adhesive, 55 parts of thermoplastic polyurethane elastomer, and 0.5 part of antioxidant; its preparation method includes the following step:

[0034] (1) Selection of raw materials;

[0035] (2) Polyester hot melt adhesive, thermoplastic polyurethane elastomer and antioxidant are mixed evenly in the high mixer;

[0036] (3) Put the uniformly mixed raw materials into the twin-screw extrusion granulation unit, melt blending and extruding;

[0037] Extrusion temperature: the temperature from the barrel to the head is 170°C, 175°C, 175°C, 175°C, 175°C, 180°C;

[0038] Host speed: 100rpm;

[0039] Feeding speed: 20rpm;

[0040] (4) The extruded mixture is water-cooled and granulated, and the extruded pellets are dried in a vacuum oven for 12 hours at a temperature of 80°C, and then the dried pellets are extrude...

Embodiment 3

[0042] A low-temperature-resistant modified polyester hot-melt adhesive, characterized in that its composition and mass content include: 80 parts of polyester hot-melt adhesive, 20 parts of thermoplastic polyurethane elastomer, and 0.5 part of antioxidant; its preparation method includes the following step:

[0043] (1) Selection of raw materials;

[0044] (2) Polyester hot melt adhesive, thermoplastic polyurethane elastomer and antioxidant are mixed evenly in the high mixer;

[0045] (3) Put the uniformly mixed raw materials into the twin-screw extrusion granulation unit, melt blending and extruding;

[0046] Extrusion temperature: the temperature from the barrel to the head is 170°C, 175°C, 175°C, 175°C, 175°C, 180°C;

[0047] Host speed: 100rpm;

[0048] Feeding speed: 20rpm;

[0049] (4) The extruded mixture is water-cooled and granulated, and the extruded pellets are dried in a vacuum oven for 12 hours at a temperature of 80°C, and then the dried pellets are extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com