Selective water blocking agent made from oil residue or oily sludge and preparation method thereof

A water blocking agent and selective technology, applied in the field of selective water blocking agent and its preparation, can solve the problems of expensive extraction agent, secondary pollution, complicated operation, etc., to expand the swept volume of injected water, increase seepage resistance, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

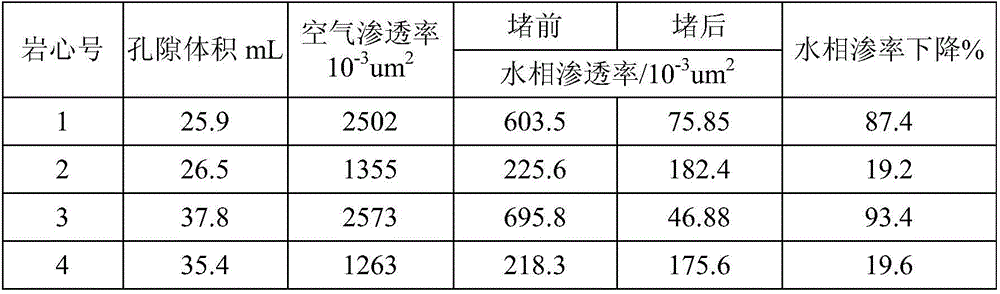

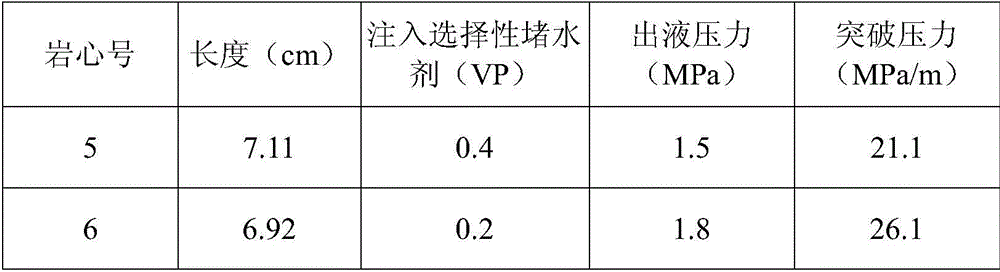

Examples

Embodiment 1

[0031] This embodiment provides a selective water shutoff agent made of oil residue. In terms of mass percentage, the raw materials for preparing the selective water shutoff agent are:

[0032] Oil residue: 20%, the oil residue has a sand content ratio of 10%, an oil content ratio of 20%, and a particle size of 10-100 μm;

[0033] Petroleum asphalt: 5%;

[0034] Cocamidopropyl Betaine: 0.2%;

[0035] Silok7007 (polyester hyperdispersant): 0.5%;

[0036] Rubber powder: 5%;

[0037] The balance is oilfield sewage.

[0038] The specific preparation process is:

[0039] (1) Heat the petroleum asphalt to 80-90°C to melt it;

[0040] (2) Cocamidopropyl betaine and hyperdispersant Silok7007 are added to the above-mentioned petroleum pitch, stirred evenly to obtain the first emulsion, and the stirring speed is 300r / min;

[0041] (3) adding oil residue and oilfield sewage into the above-mentioned first emulsion, stirring evenly to obtain the second emulsion;

[0042] (4) Add rub...

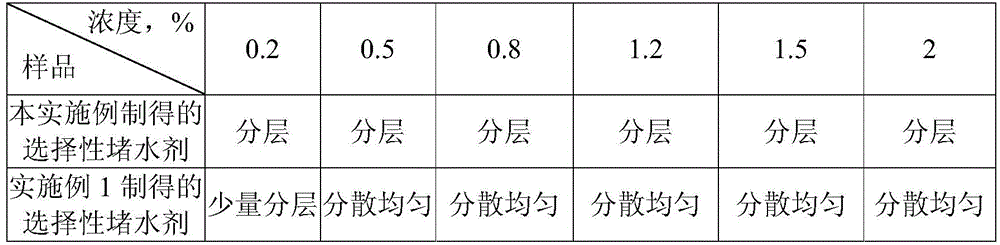

Embodiment 2

[0044] This embodiment provides a selective water shutoff agent that does not contain a hyperdispersant. In terms of mass percentage, the raw materials for preparing the selective water shutoff agent are:

[0045] Oil residue: 20%, the oil residue has a sand content ratio of 10%, an oil content ratio of 20%, and a particle size of 10-100 μm;

[0046] Petroleum asphalt: 5%;

[0047] Cocamidopropyl Betaine: 0.2%;

[0048] Rubber powder: 5%;

[0049] The balance is oilfield sewage.

[0050] The specific preparation process is:

[0051] (1) Heat the petroleum asphalt to 80-90°C to melt it;

[0052] (2) Cocamidopropyl betaine is added in the above-mentioned petroleum pitch, stir evenly, obtain the first emulsion, and stirring speed is 300r / min;

[0053] (3) adding oil residue and oilfield sewage into the above-mentioned first emulsion, stirring evenly to obtain the second emulsion;

[0054] (4) Add rubber powder to the above emulsion, and continue to stir for half an hour to ...

Embodiment 3

[0060] This embodiment provides a selective water shutoff agent made from oily sludge. In terms of mass percentage, the raw materials for preparing the selective water shutoff agent are:

[0061] Oily sludge: 30%, the oily sludge has a sand ratio of 20%, an oil ratio of 40%, and a particle size of 10-100 μm;

[0062] Coal tar pitch: 20%;

[0063] Lauramidopropyl Betaine: 1%;

[0064] Octylphenol polyoxyethylene ether OP-4 (polyether hyperdispersant): 2%;

[0065] Rubber powder: 10%;

[0066] The rest of the water.

[0067] The specific preparation process is:

[0068] (1) Heating the coal tar pitch to 80-90°C to melt it;

[0069] (2) Add lauryl amidopropyl betaine and hyperdispersant octylphenol polyoxyethylene ether OP-4 to the above-mentioned coal tar pitch, stir evenly to obtain the first emulsion, and the stirring speed is 300r / min;

[0070] (3) adding oily sludge and clear water to the above-mentioned first emulsion, stirring evenly to obtain a second emulsion;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com