A shaft connecting rod transmission system and an opposed piston engine

A technology of connecting rod transmission and opposed pistons, which is applied in transmission devices, machines/engines, mechanical equipment, etc., can solve the problems of complex limit mechanism, mechanical wear and noise, impact of left and right baffles, etc., and achieve simplified transmission system and Gas distribution system, reduce mechanical wear and noise, and eliminate the effect of transition impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

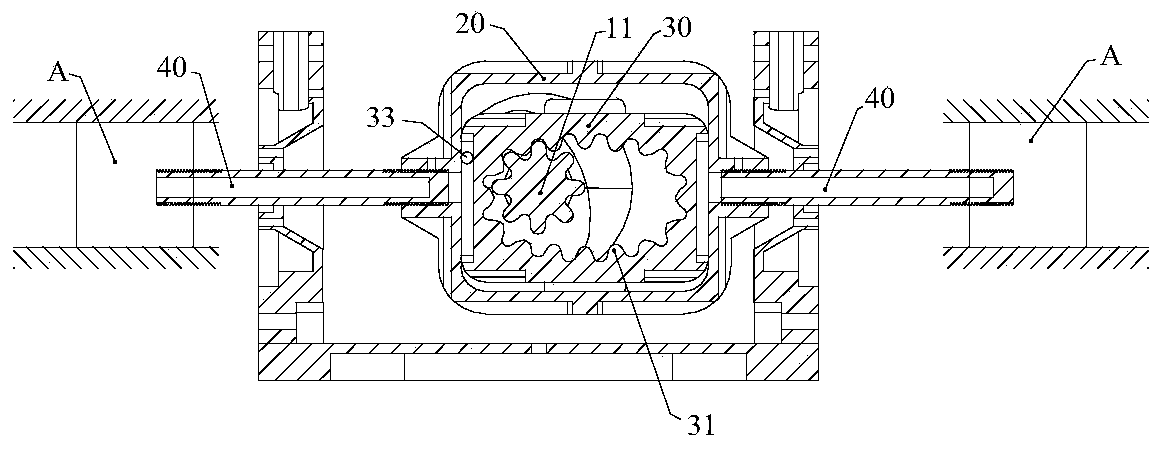

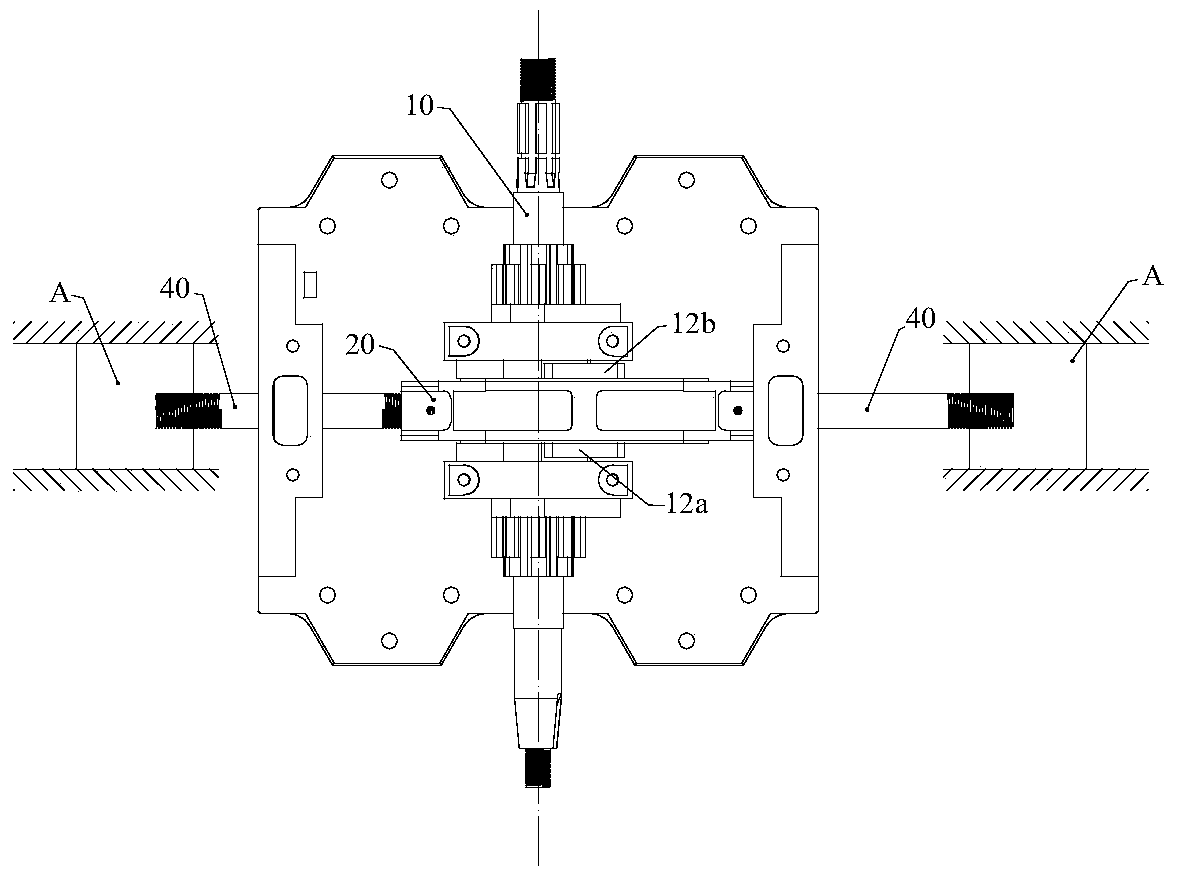

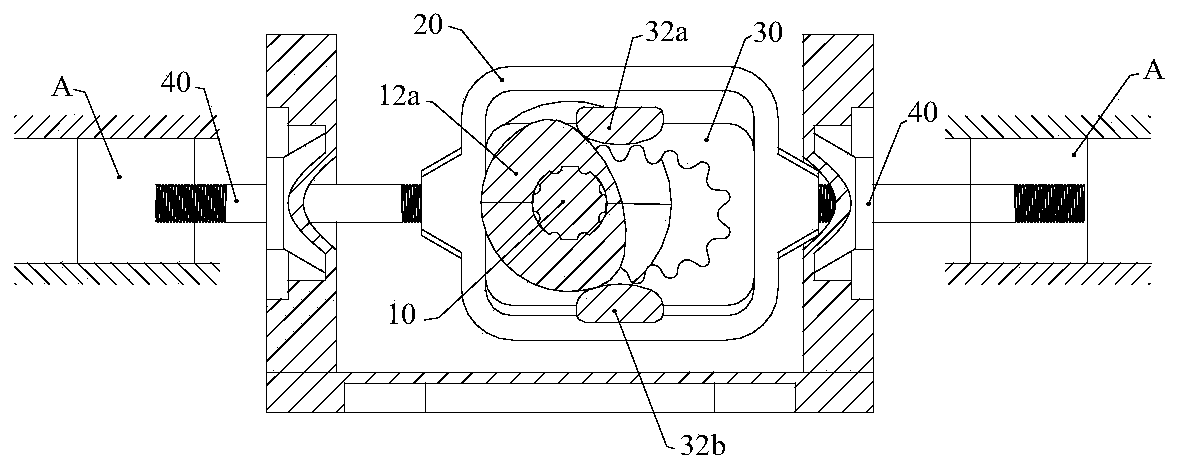

[0042] Figure 6 to Figure 9 Shown is a two-stroke, opposed-piston engine. Taking the axis of the main shaft 10 as the reference center, the pistons close to the axis are called "inner pistons", and the pistons farther from the axis than the "inner pistons" are called "outer pistons". Equally, the axle-type connecting rod that is fixedly connected with " inside piston " is referred to as " inside axle-type connecting rod ", and the axle-type connecting rod that is fixedly connected with " outside piston " is called " outer frame shape axle-type connecting rod ".

[0043] refer to Figure 6 , Figure 7 , the opposed-piston engine of the present invention includes at least one pair of rectilinear reciprocating units arranged on the planes on both sides of the axis of the main shaft 10, and its rectilinear reciprocating unit A includes an inner piston 51a and an outer piston 51b arranged in the cylinder 50. The shaft connecting rod 40 includes an inner shaft connecting rod 40a...

Embodiment 2

[0054] Figure 10 and Figure 11 What is shown is a four-stroke opposed-piston engine, including at least one pair of linear reciprocating units arranged on the planes on both sides of the axis of the main shaft 10 , and the linear reciprocating body A is a piston 51 arranged in a cylinder 50 . The shaft connecting rod 40 is an inner shaft connecting rod 40a whose outer end is fixedly connected to the piston 51, the push-pull frame 20 is the first push-pull frame 20a, and the inner end of the inner shaft type connecting rod 40a is connected to the first push-pull frame. One side of 20a is fixedly connected. An intake valve 57 and an exhaust valve 58 are arranged on the outer end cover 52b of the cylinder 50, and a timing system is arranged between the main shaft 10, the intake valve 57, and the exhaust valve 58, and the timing system operates in a four-stroke mode. Gas distribution.

[0055] Described timing system can adopt multiple conventional devices, as belt timing sys...

Embodiment 3

[0062] Figure 12 and Figure 13 Shown is a two-stroke opposed-piston engine, the opposed-piston engine includes at least a pair of linear reciprocating units arranged on the planes on both sides of the axis of the main shaft 10, and the linear reciprocating body A is arranged in the cylinder 50 Piston 51. The shaft connecting rod 40 is an inner shaft connecting rod 40 a whose outer end is fixedly connected to the piston 51 , and the push-pull frame 20 is the first push-pull frame 20 a. The inner end of the inner shaft connecting rod 40a is fixedly connected to one side of the first push-pull frame 20a, and an exhaust valve 58 is arranged on the outer end cover 52b of the cylinder 50, and a timing system is arranged between the main shaft 10 and the exhaust valve 58. , the timing system cooperates with the air inlet 55 controlled by the piston stroke to perform air distribution in a two-stroke working mode.

[0063] refer to Figure 13 , the timing system includes the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com