Comprehensive purification method for indoor volatile organic contaminants, formaldehyde, mites, avian influenza viruses and atmospheric particulates

A technology for atmospheric particulate matter and avian influenza virus, which is applied in the field of indoor air purification, can solve problems such as no reported measures to prevent infected mites from spreading mites in humans, and no one has studied comprehensive treatment methods, so as to facilitate human-machine interaction and eliminate indoor air pollution. Odor and health protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the comprehensive purification method of indoor volatile organic pollutants, formaldehyde, mites, avian influenza virus and atmospheric particulate matter provided by this embodiment, firstly, a polymer adsorption material is installed indoors, and the polymer adsorption material adsorbs and catalyzes the purification of indoor atmospheric particulate matter, and then adopts Chlorine dioxide gas with a purity higher than 99.5% diffuses into the room. While oxidizing and purifying indoor organic pollutants, formaldehyde, mites and avian influenza viruses, chlorine dioxide gas can also enter the interior of the polymer adsorption material. The adsorbed atmospheric particulate matter is oxidized and purified and the polymer adsorption material is regenerated in situ. Through the combination of the adsorption and catalytic purification of the polymer adsorption material and the oxidation purification of chlorine dioxide gas, the organic pollutants, formaldehyde, mites and ...

Embodiment 2

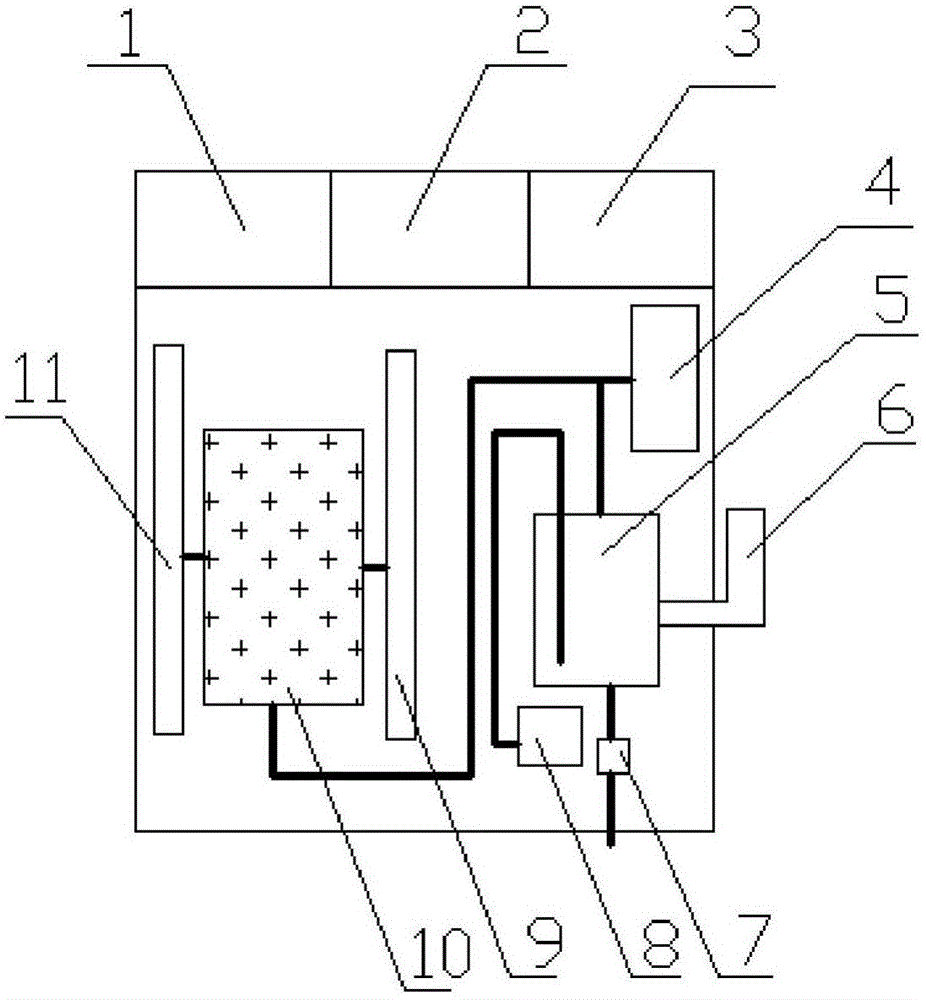

[0038] The comprehensive purification equipment for indoor volatile organic pollutants, formaldehyde, mites, avian influenza viruses and atmospheric particles provided in this embodiment, such as figure 1 As shown in the figure, it includes a polymer material adsorption device and a high-purity chlorine dioxide generating device. The polymer material adsorption device includes a polymer adsorption chamber 10. The polymer adsorption chamber 10 is equipped with a polymer adsorption material for adsorbing atmospheric particles. One side of the adsorption chamber 10 is provided with a fan 11, and the other side is provided with a polymer chamber diffuser 9. The indoor air enters the polymer adsorption chamber 10 through the fan 11 and is released by the polymer chamber diffuser 9 after being adsorbed and purified. The pure chlorine dioxide generating device includes an air compressor 8, a high-purity chlorine dioxide gas vaporizer 5, a chlorine dioxide liquid inlet 6 and a chlorine...

Embodiment 3

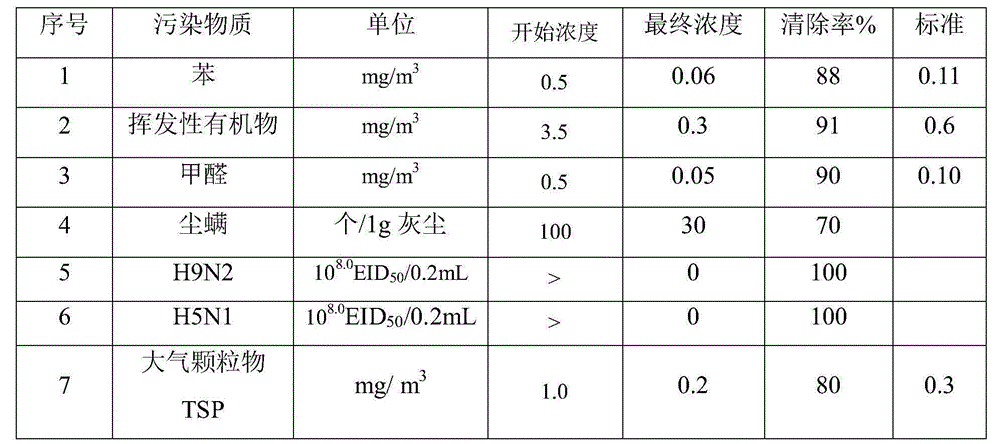

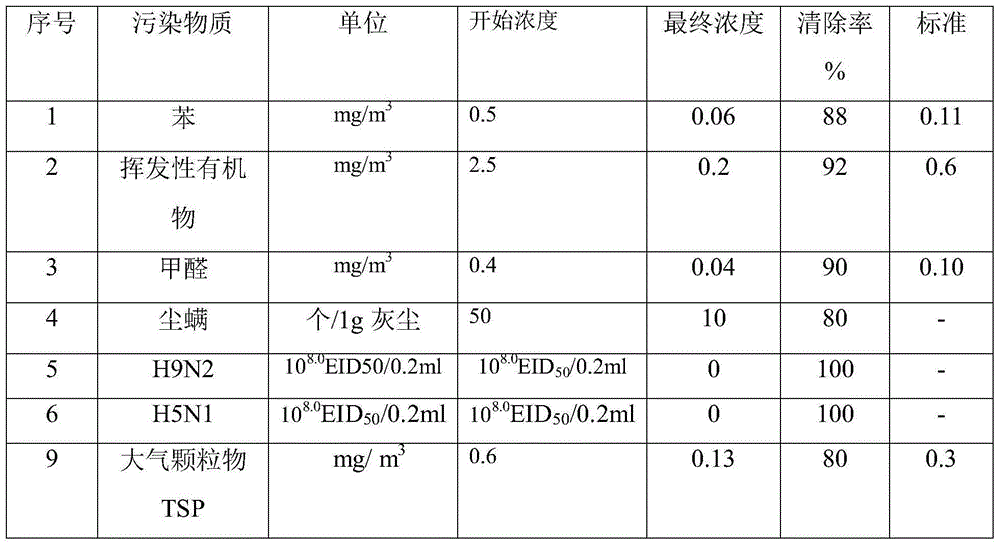

[0042] by 6m 3 The sealed environmental test chamber (made of stainless steel) is the test environment, and dust particles TSP are placed on the ground of the environmental test chamber; benzene, volatile organic pollutants, benzene, and formaldehyde are injected with a syringe; mites and chicken are placed on old clothes. flu virus.

[0043] The initial concentration of high-purity chlorine dioxide is shown in Table 1, and the equipment (the purification equipment in Example 2) is put into the environmental test chamber, and the gas distribution positive pressure technology is adopted. The molar ratio of : 4 is added to the high-purity chlorine dioxide gas gasifier 5 for reaction, and the gasification generates high-level chlorine dioxide gas with a purity of 100% and is mixed with compressed air. ClO after half an hour 2 Concentration is 100mg / m 3 , ClO after 1 h of diffusion 2 Concentration is 150mg / m 3 , Evaluate the final concentration of volatile organic pollutants,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com