Method of preparing various single-side multilayer single-functional and single-side and double-side multilayer multifunctional printed electronic product by virtue of light induction

An electronic product, light-induced technology, applied in the direction of electric recording technology, printed circuit, conductive pattern formation, etc., which can solve the problems of high efficiency, high resolution, and large-scale electronic circuit production, and achieve green Environmentally friendly and efficient production, no waste liquid, and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

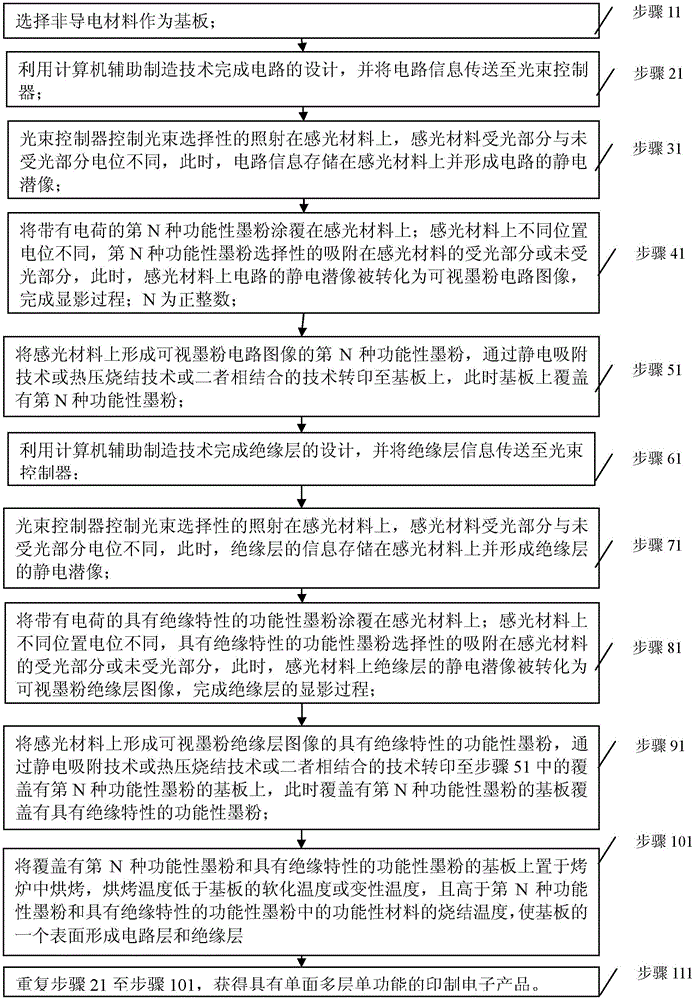

[0039] Specific implementation mode 1, refer to figure 1 Specifically explain this embodiment, the method for preparing a single-sided multi-layer single-function printed electronic product using light induction described in this embodiment, it includes the following steps:

[0040] Step 11, selecting a non-conductive material as the substrate;

[0041] Step 21, using computer-aided manufacturing technology to complete the design of the circuit, and sending the circuit information to the beam controller;

[0042] Step 31, the light beam controller controls the light beam to selectively irradiate the photosensitive material, and the potential of the light-receiving part of the photosensitive material is different from that of the non-light-receiving part. At this time, the circuit information is stored on the photosensitive material and forms an electrostatic latent image of the circuit;

[0043]Step 41, coating the Nth functional toner with charge on the photosensitive materi...

specific Embodiment approach 2

[0054] Embodiment 2. Based on Embodiment 1, the method for preparing a double-sided multilayer single-function printed electronic product includes the following steps:

[0055] Step 1-1, selecting a non-conductive material as the substrate;

[0056] Step 2-1, using computer-aided manufacturing technology to complete the design of the circuit, and sending the circuit information to the beam controller;

[0057] Step 3-1, the light beam controller controls the light beam to selectively irradiate the photosensitive material, and the potential of the light-receiving part of the photosensitive material is different from that of the non-light-receiving part. At this time, the circuit information is stored on the photosensitive material and forms an electrostatic latent image of the circuit;

[0058] Step 4-1, coating the Nth functional toner with charge on the photosensitive material; different positions on the photosensitive material have different potentials, and the Nth functiona...

specific Embodiment approach 3

[0068] Specific Embodiment Three. The method for preparing a single-sided multi-layer single-function printed electronic product using light induction described in this embodiment includes the following steps:

[0069] Step A, selecting a non-conductive material as the substrate;

[0070] Step B, using computer-aided manufacturing technology to complete the design of the circuit, and sending the circuit information to the beam controller;

[0071] Step C, the light beam controller controls the light beam to selectively irradiate the photosensitive material, and the potential of the light-receiving part of the photosensitive material is different from that of the non-light-receiving part. At this time, the circuit information is stored on the photosensitive material and forms an electrostatic latent image of the circuit;

[0072] Step D, coating the Nth functional toner with charge on the photosensitive material; different positions on the photosensitive material have different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com