Predictive control method, device and system for precision hydrostatic guide rail

A hydrostatic guideway and predictive control technology, applied in fluid pressure actuation devices, special data processing applications, instruments, etc., can solve the problems of complex and variable control of processing loads, lag, etc., to facilitate intelligent control and eliminate response Hysteresis, control the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

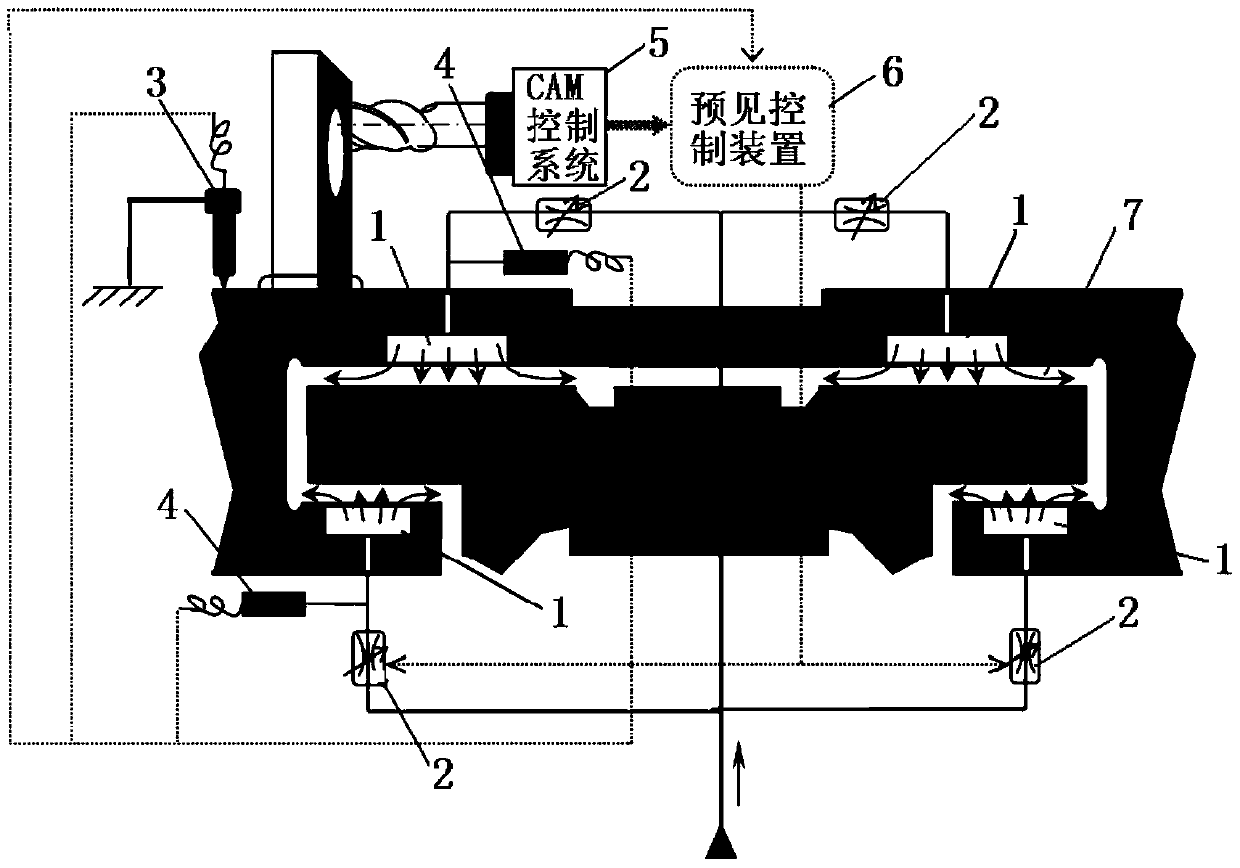

[0036] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

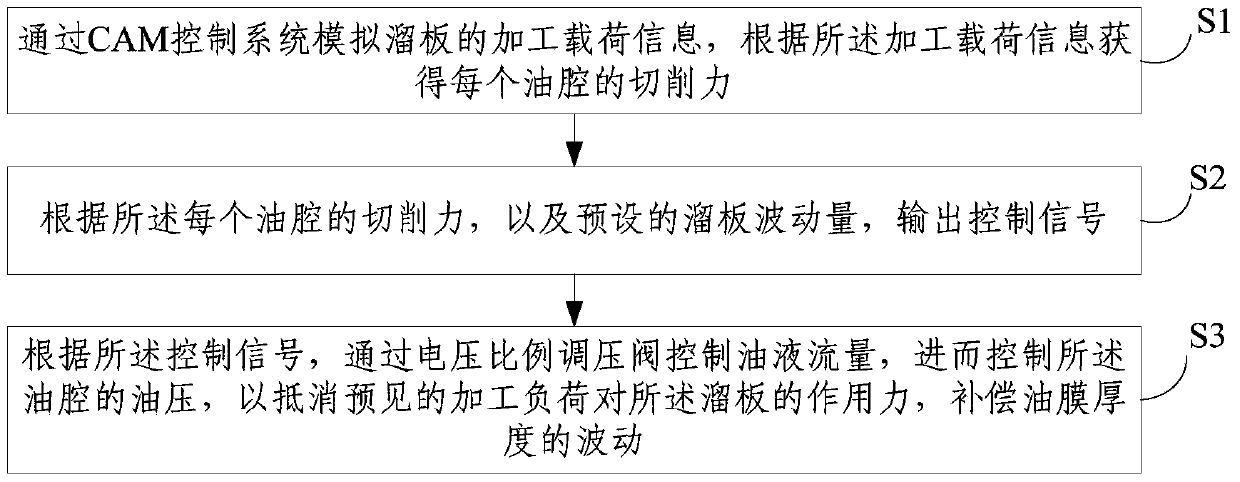

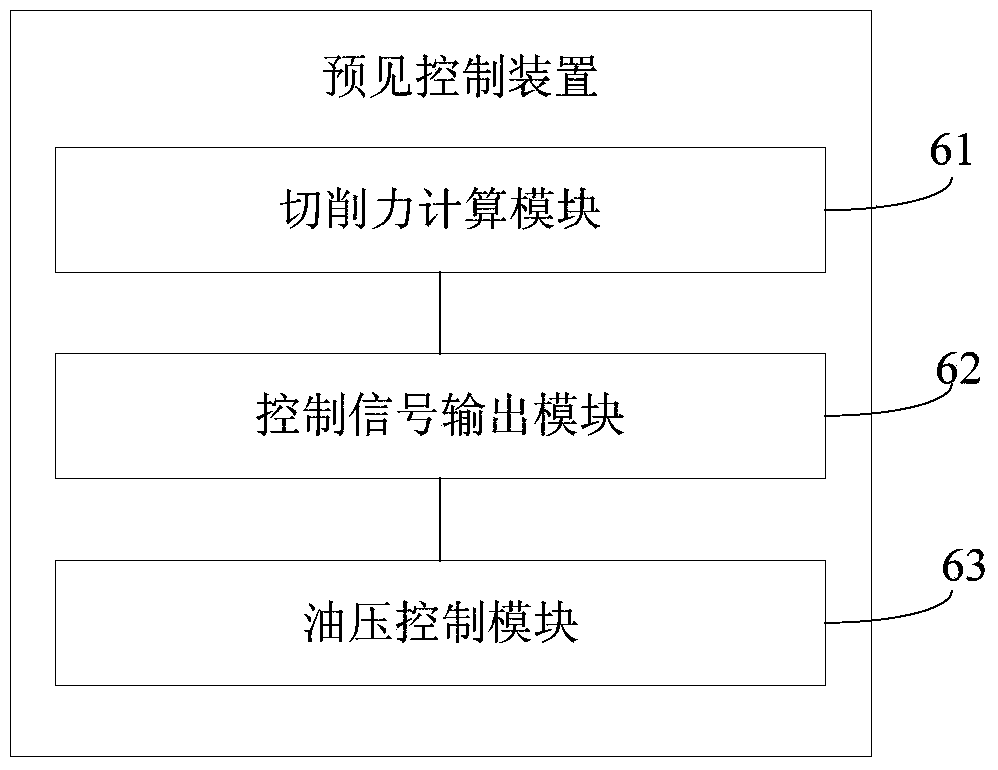

[0037] figure 1 It shows a schematic flowchart of a predictive control method for a precision hydrostatic guide rail provided by an embodiment of the present invention, including the following steps:

[0038] S1: Simulate the processing load information of the slide plate through the CAM control system, and obtain the cutting force of each oil chamber according to the processing load information.

[0039] Under the background of precision numerical control machining technology, the CAM control system that pre-plans the toolpath path according to the initial and final parameters of the workpiece and the numerical control (NC) program has come out, and the relationship between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com