Method for manufacturing bearing ring member

A manufacturing method and component technology, which are applied to vehicle components, rotating components that resist centrifugal force, bearing components, etc., can solve the problems of increased processing cost, increased material cost, low machinability, etc., and achieve the effect of suppressing manufacturing cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

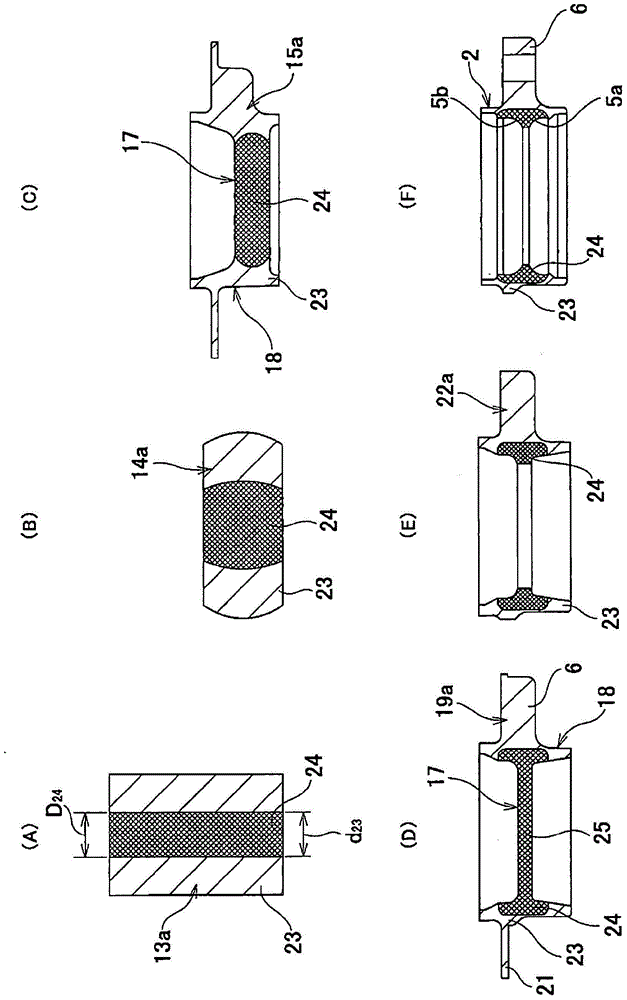

[0046] figure 1 (A)~ figure 1 (F) shows the first embodiment of the present invention. The object of the manufacturing method of the ferrule part of this example is the rolling bearing unit 1 for wheel support (refer to Figure 14 In addition to the outer ring 2 of ), the outer ring constituting various radial rolling bearings, the ball nut constituting the ball screw, and various ferrule parts with a raceway surface formed on the inner peripheral surface are also objects of this example .

[0047] In the manufacturing method of this example, first prepare figure 1 (A) The metal cylindrical blank 13a shown in FIG. In the case of this example, the blank 13a has the first metal part 23 and the figure 1 The second metal part 24 shown in diagonal grids. The first metal portion 23 is formed in a cylindrical shape by a metal member made of surface hardened steel such as machine structural steel or SCM420. When the second metal part 24 forms the outer ring raceways 5a, 5b of the ou...

no. 2 approach

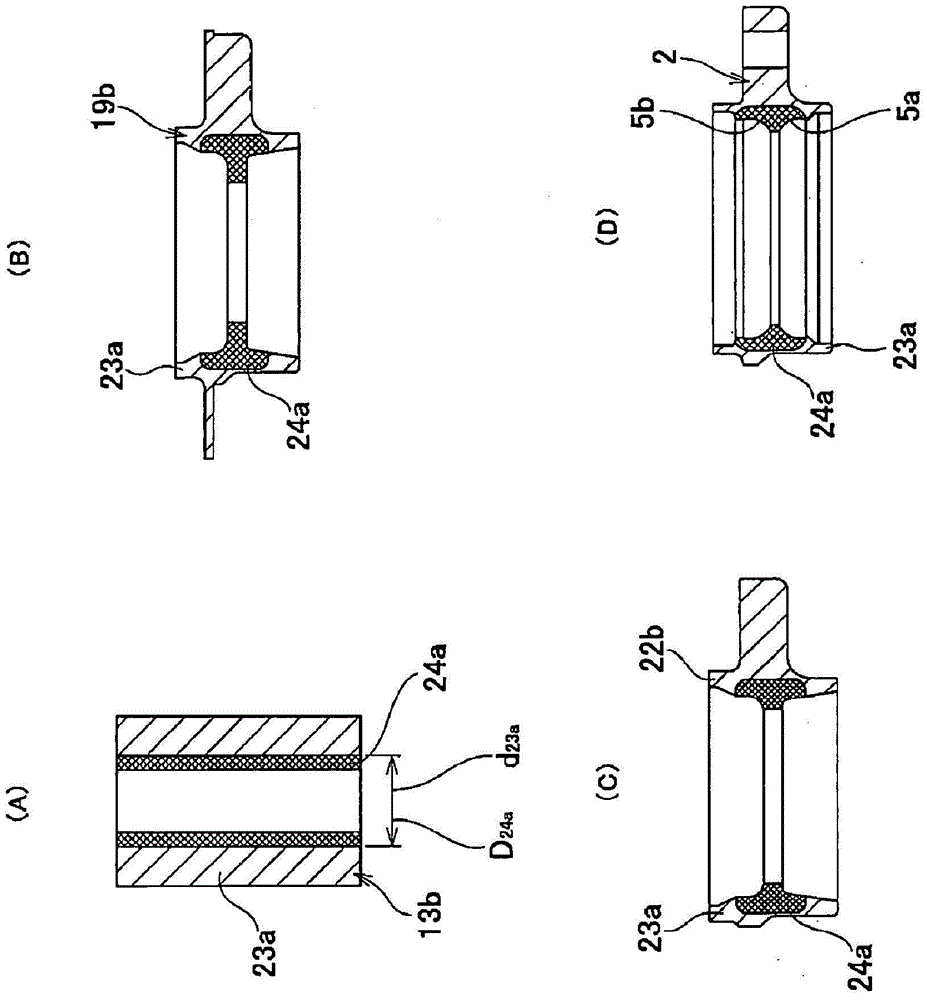

[0056] figure 2 (A) to figure 2 (D) shows the second embodiment of the present invention. In this example, as in the first embodiment, the rolling bearing unit 1 for wheel support (refer to Figure 14 ) Outer ring 2 is the object. In this example, prepare figure 2 The metal cylindrical blank 13b shown in (A). The blank 13b has a first metal part 23a and figure 2 The second metal part 24a is indicated by diagonal grids. The first metal portion 23a is formed in a cylindrical shape by a metal member made of surface hardened steel such as machine structural steel or SCM420. The second metal portion 24a is formed into a cylindrical shape by a metal member made of two types of high carbon chromium bearing steel (SUJ2) having higher fatigue strength or wear resistance than the first metal portion 23a when forming the outer ring raceways 5a, 5b. The outer diameter dimension D of the cylindrical metal member constituting the second metal portion 24a 24a And the inner diameter dimen...

no. 3 approach

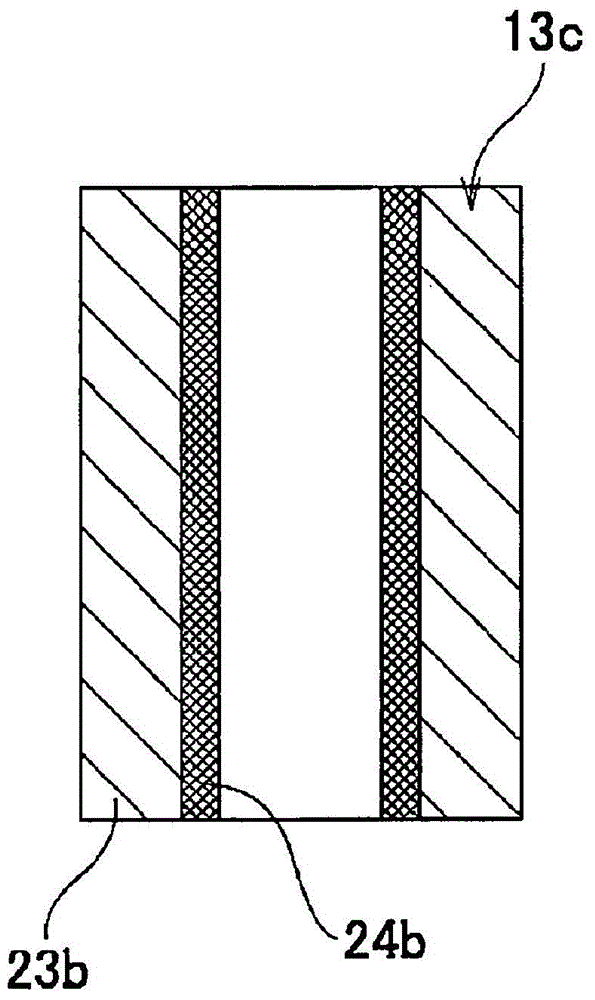

[0059] image 3 This shows the third embodiment of the present invention. In this example, as in the first embodiment, the rolling bearing unit 1 for wheel support (refer to Figure 14 ) Outer ring 2 is the object. In this example, prepare image 3 A cylindrical blank 13c made of metal is shown. The blank 13c is composed of a metal part such as mechanical structural steel and high-carbon chromium bearing steel. The radially outer cylindrical portion of the blank 13c, that is, the portion from the outer circumferential surface of the blank 13c to about 60% to 70% of the radial thickness, preferably from the outer circumferential surface of the blank 13c to the radial thickness Approximately 2 / 3 is the first metal part 23b. In addition, put the blank 13c in image 3 The cylindrical portion at the radially inner end shown in the diagonal lattice, that is, the portion from the inner peripheral surface of the blank 13b to about 30% to 40% of the radial thickness, preferably from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com